C10 self-compacting concrete and preparation method for same

A self-compacting concrete and concrete technology, applied in the field of building materials, can solve the problems of easily damaged machinery and cutter head, unfavorable shield and pipe jacking construction, and high compressive strength, and achieves a wide range of uses, guarantees work performance, guarantees The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

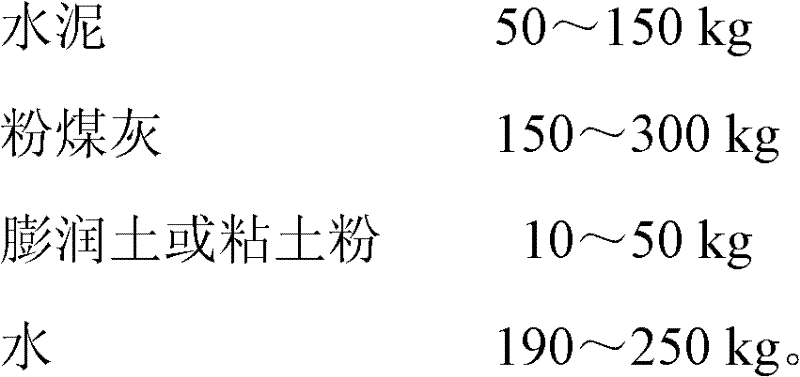

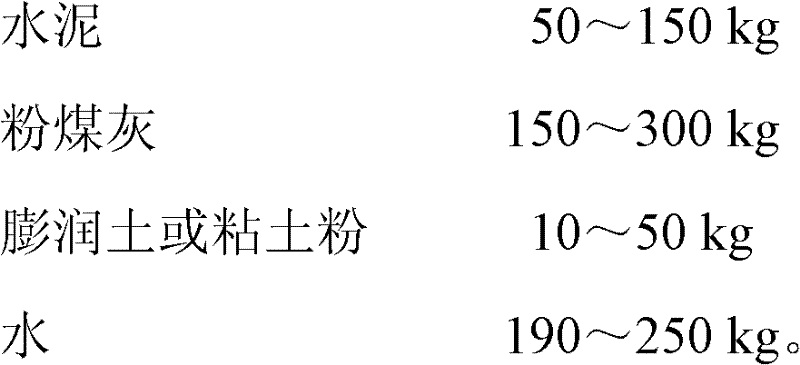

Method used

Image

Examples

Embodiment 1

[0022] Concrete mix ratio: 60kg of cement, 250kg of fly ash, 900kg of medium sand, 920kg of 5-10mm stone, 20kg of bentonite, 220kg of water, and 3.3kg of high-performance water reducer. The concrete prepared according to this mix ratio has been applied in the underground pipe jacking enclosure structure of the Nangui Road Station Crossing Tunnel Project of the Guangzhou-Foshan Intercity Rail Transit, with a total production of 600m 3 . The concrete has good workability, the slump reaches 250mm, and the 28-day compressive strength reaches 10.6MPa. There is no water seepage in the concrete diaphragm wall, the jacking machine is normal, and there is no abnormal damage to the cutter head.

Embodiment 2

[0024] Concrete mix ratio: 150kg of cement, 150kg of fly ash, 930kg of medium sand, 940kg of 5-10mm stone, 10kg of bentonite, 190kg of water, and 2.9kg of high-performance water reducer. The concrete prepared according to this mix ratio is used in the GZH-12 standard shield construction of Guangdong Guanhui Intercity Rail Transit Passenger Dedicated Line, and the total production of concrete is about 6500m 3 , the shield machine advances normally, and there is no abnormal damage to the cutter head and cutter head. The slump reaches 240mm, the standard curing is 28 days, and the compressive strength reaches 16.1MPa.

Embodiment 3

[0026] Concrete mix ratio: 50kg of cement, 300kg of fly ash, 850kg of medium sand, 870kg of 5-10mm stone, 50kg of clay powder, 250kg of water, and 4.2kg of high-performance water reducer. The concrete prepared according to this mix ratio has been applied in the pipe jacking ground reinforcement structure of the 220KV Kexiang Road high-voltage overhead line relocation project in Guangzhou City, with a total production of 1500m 3 . The concrete has good workability, the slump reaches 260mm, and the 28-day compressive strength reaches 9.8MPa. There is no water seepage in the concrete diaphragm wall, the jacking machine is normal, and there is no abnormal damage to the cutter head.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com