Supercritical water treatment reactor for organic wastes

A supercritical water and reactor technology, which is used in the removal of solid waste, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as reducing the corrosion rate of the reactor and reducing the deactivation rate of the catalyst. , to reduce the cost, avoid blockage, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

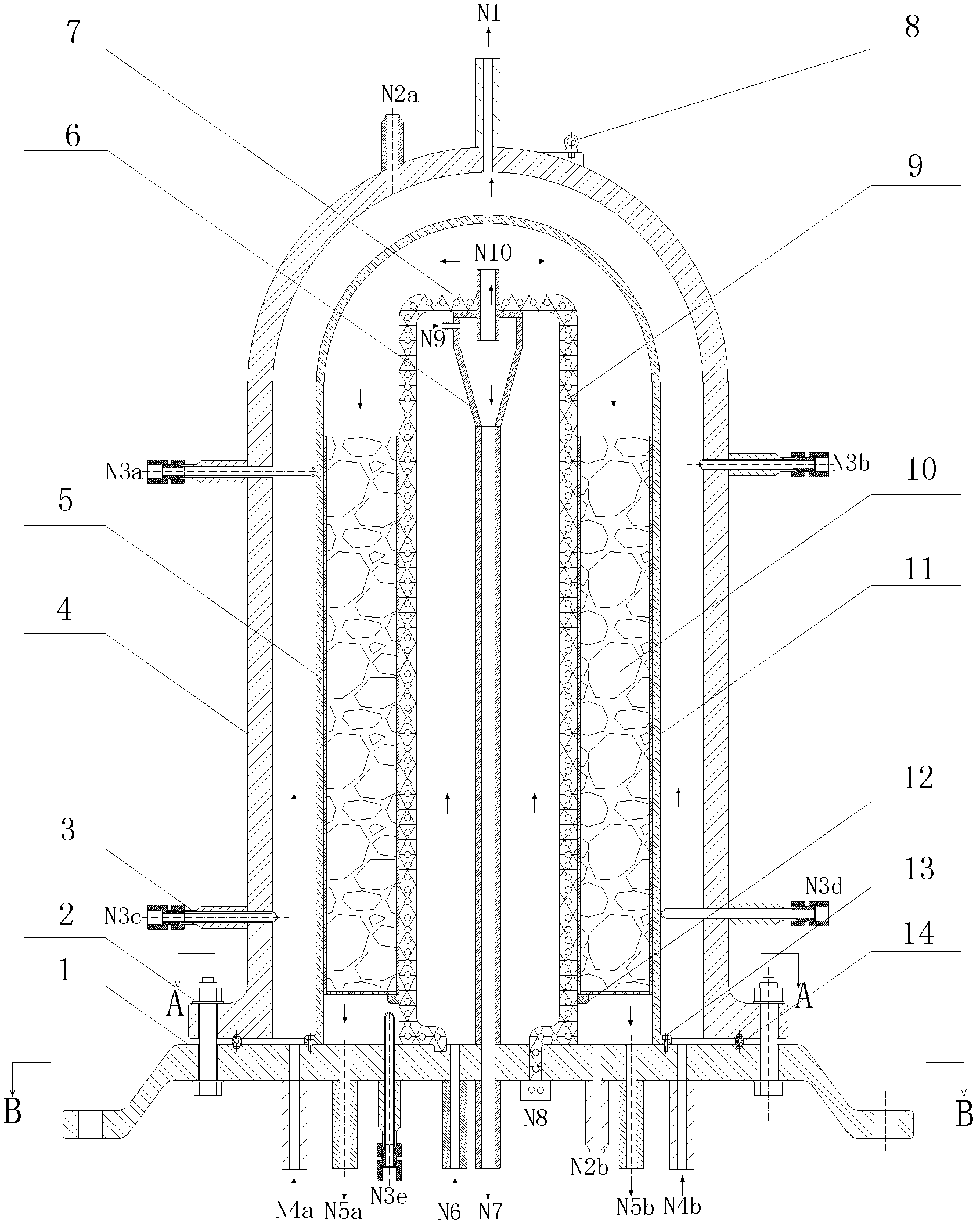

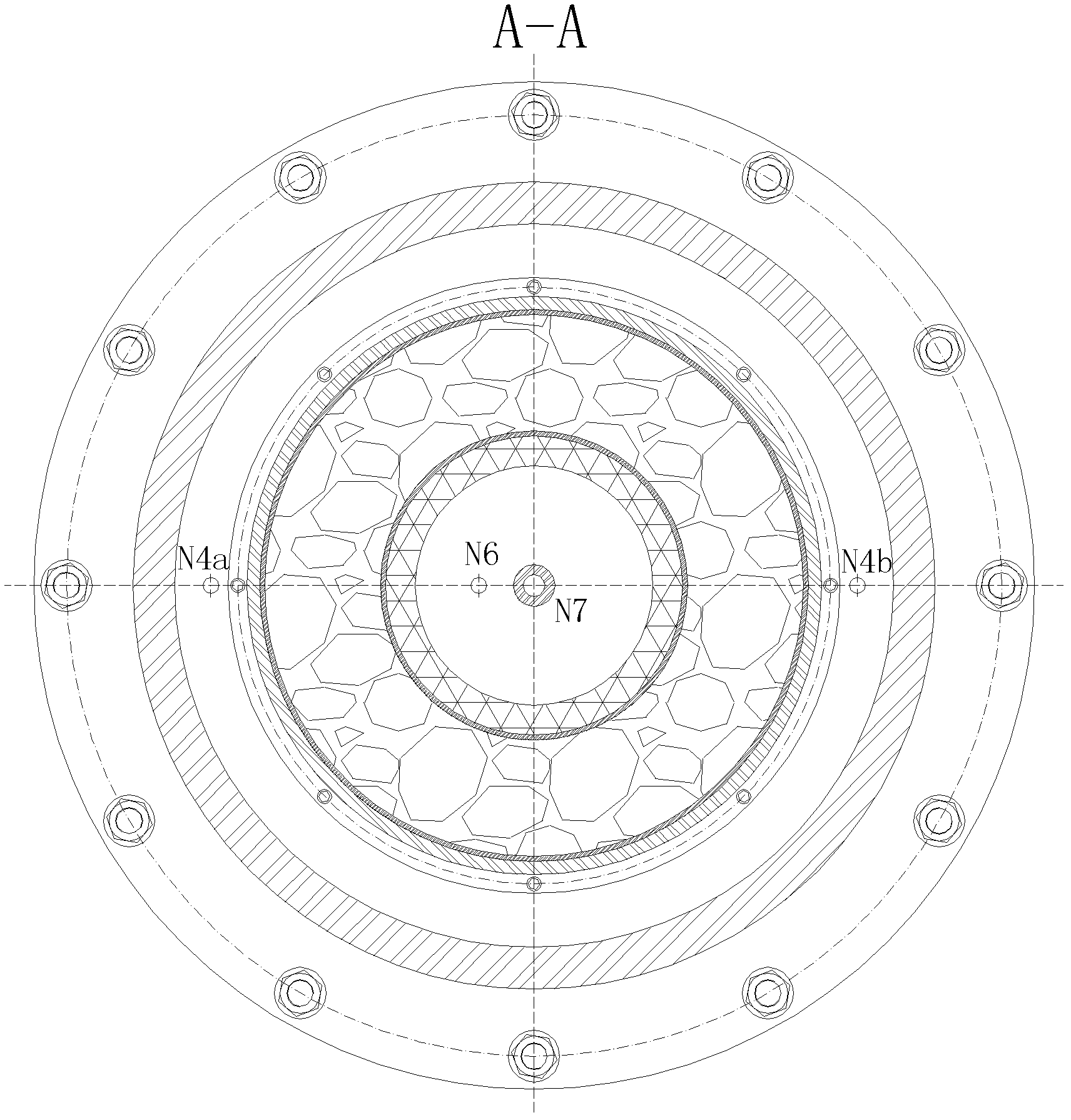

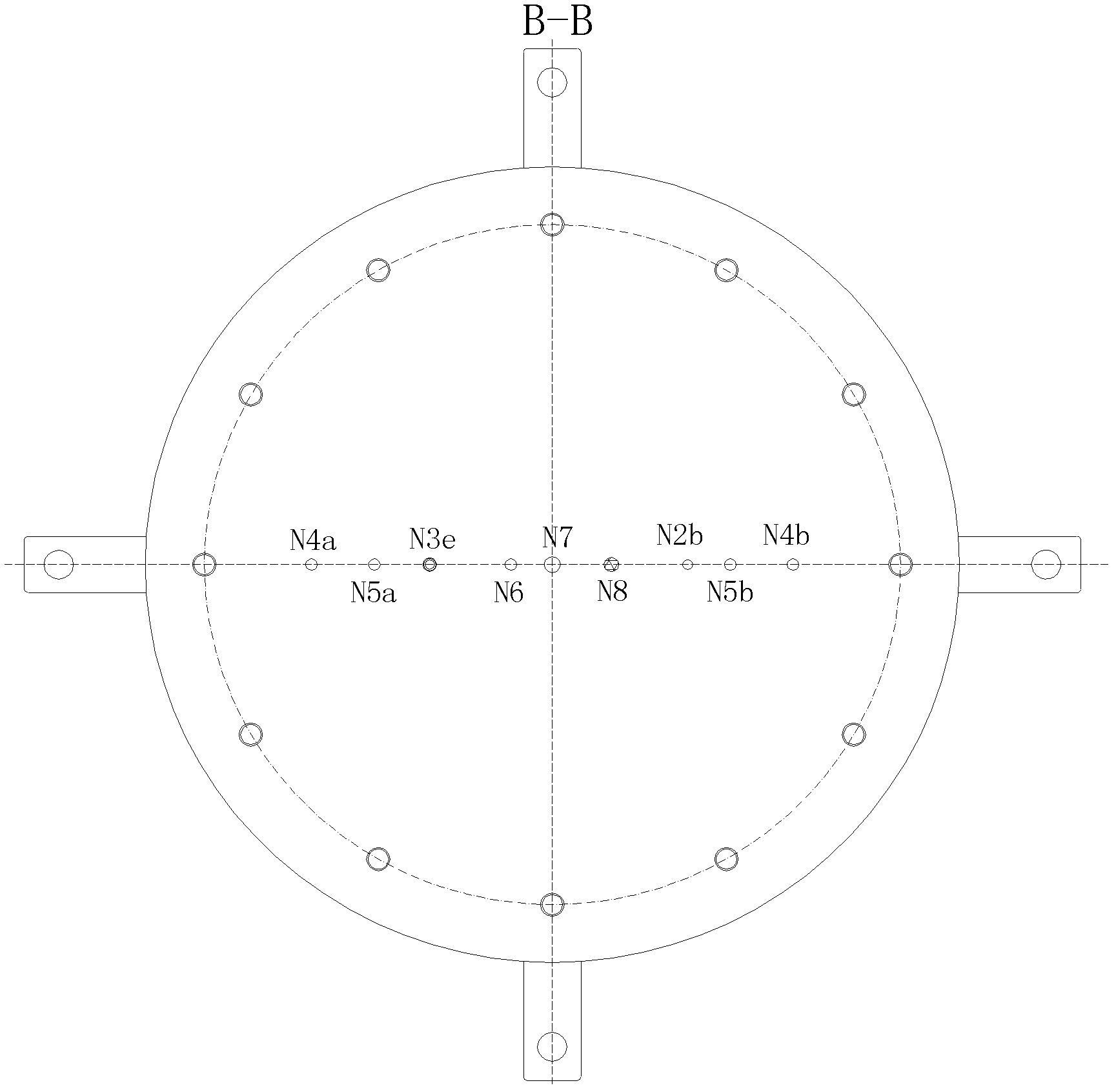

[0020] Reference figure 1 , figure 2 with image 3 , A reactor for supercritical water treatment of waste organic matter, including a pressure-bearing wall 4 connected by a bolt assembly 2 (sealed with an octagonal gasket 14) on the base 1, an insulating heat-conducting wall 7 with an electric heating wire 9 inside, and a screw 13 The corrosion-resistant wall 11 fixed on the base 1, the hydrocyclone 6 for salt separation, the catalyst box 5 for loading the catalyst, the support ring 12 for supporting the catalyst box 5 on the insulating heat conducting wall 7, and the bearing The thermocouple interfaces N3a, N3b, N3c, N3d, N3e on the pressure wall and the base for measuring the temperature distribution, the pressure gauge and safety valve interfaces on the pressure wall and the base for installation N2a, N2b, and the base for communication The inlets N4a and N4b for the clean cooling water, the outlet N1 for the clean cooling water on the top of the pressure-bearing wall, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com