High-power high-voltage electric heater

A high-voltage, high-power technology, which is applied in the direction of ohmic resistance heating parts, heating element shape, ohmic resistance electrode, etc., can solve the problem of increased installation space requirements for electric heating elements, large power requirements for electric heaters, and electric heating. The problem of large heat loss of the device is solved, and the electrode connection structure is safe and reliable, the operation is convenient, and the actual pressure is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

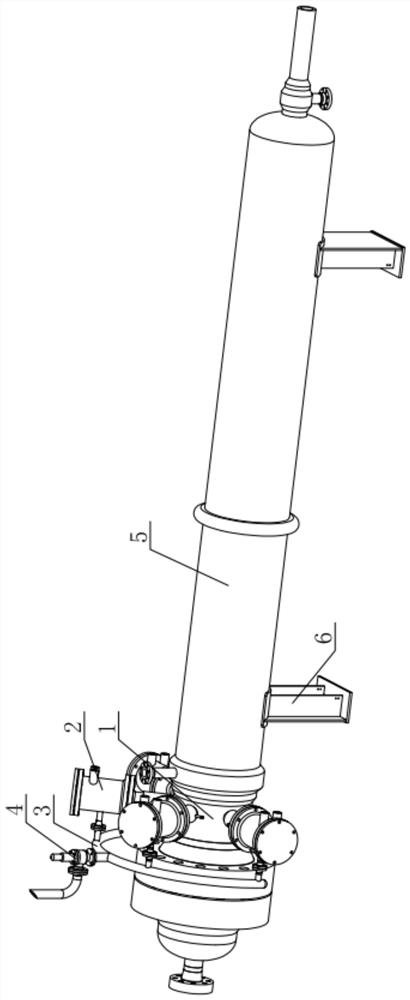

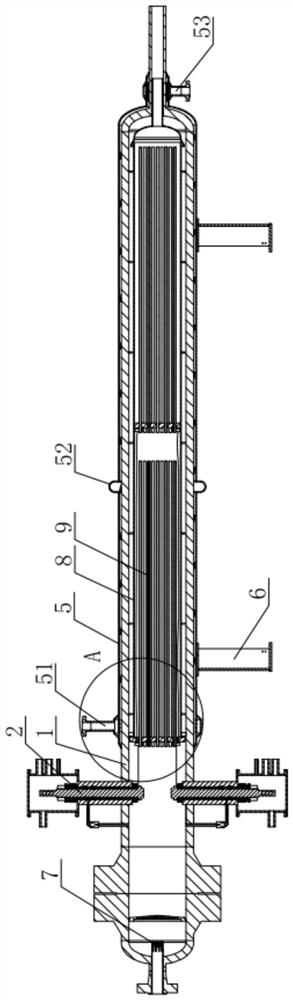

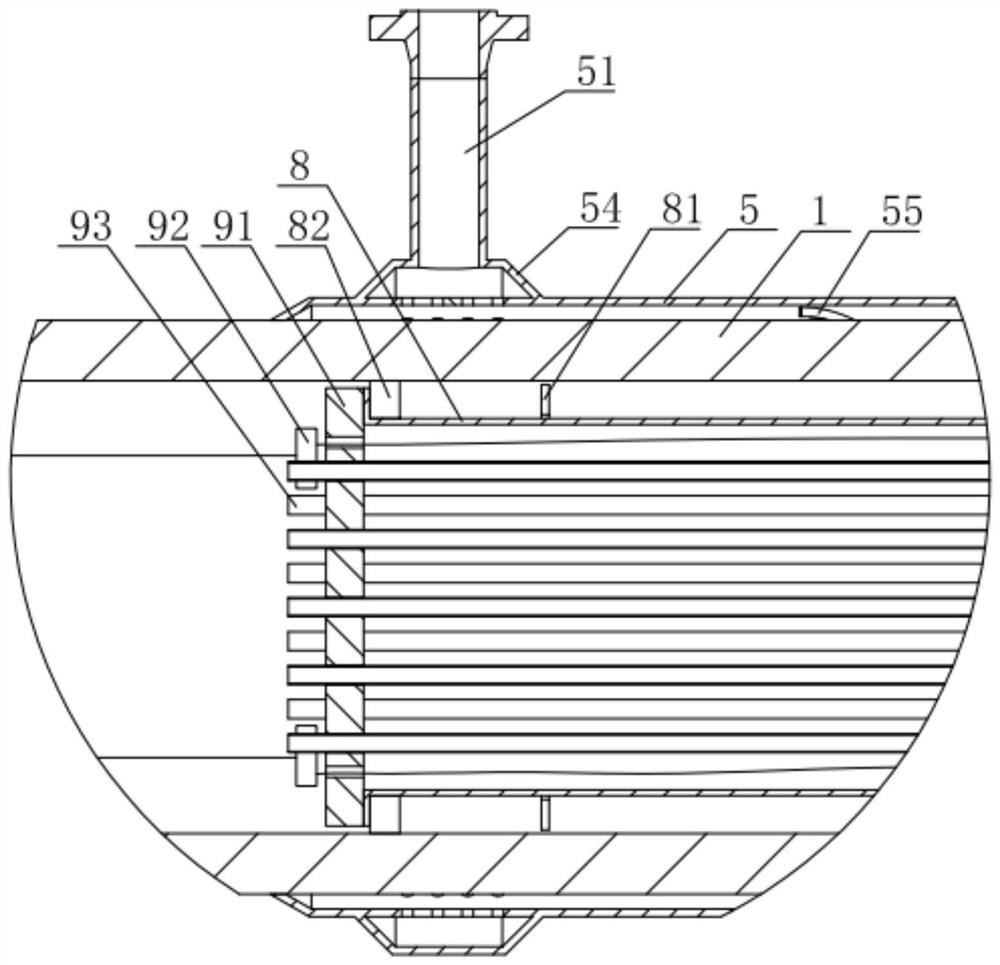

[0033] Such as figure 1 with figure 2 As shown, the high-power high-voltage electric heater of this embodiment includes a casing 1 that runs through the front and back, and the outer wall of the casing 1 is fitted with a casing 5 at intervals to form a closed space, and the two ends of the casing 5 are respectively provided with oil inlets 53 And the oil outlet 51; the inside of the shell 1 is sleeved with a pipe body 8 along the length direction, and multiple sets of heating components 9 are installed in the pipe body 8 at intervals along the length direction; the wall of the shell 1 located in front of the shell 5 A plurality of electrode assemblies 2 of the same group of power supplies are installed at intervals along the circumferential direction, and multiple sets of heating assemblies 9 are electrically connected to the group of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com