Preparation method for tin-based oxide nanorods

A technology of oxides and nanorods, applied in the field of materials, can solve the problems of expensive surfactants, complicated preparation process, uneven mixing, etc., and achieve the effects of reduced preparation cost, low post-treatment temperature and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

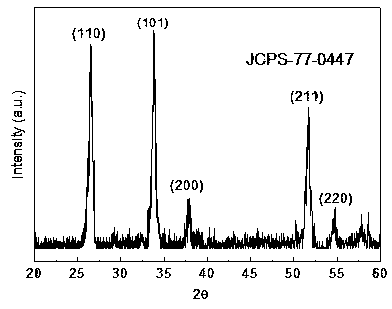

Image

Examples

Embodiment 1

[0038] Weigh 0.0929 g of Y 2 o 3 , placed in a beaker with an appropriate amount of 1:1 nitric acid solution, heated to dissolve, and then weighed 2.8042 grams of SnCl 4 ·5H 2 O, 0.211 gram of ethylene glycol, 0.1601 gram of ammonium nitrate and 0.3728 gram of KCl are added therein and heated to dissolve. When the solution is concentrated to a viscous state, it is put into a microwave oven and heated until a self-propagating combustion reaction occurs, and the combustion product is in Incubate at 400°C for 4 hours in the air, wash and dry to obtain Sn0.8 Y 0.2 o 2-δ Nano stave.

Embodiment 2

[0040] Weigh 0.3145 grams of Y (NO 3 ) 3 ·6H 2 O, 3.15477 g SnCl 4 ·5H 2 0, 0.0931 gram of ethylene glycol, 0.1601 gram of ammonium nitrate and 0.3728 gram of KCl are placed in a beaker with an appropriate volume of deionized water, heated while stirring to dissolve the reactant completely, continue heating, and when the solution is concentrated to After it is close to the viscous state, put it into a microwave oven and heat it until the self-propagating combustion reaction occurs. The combustion product is kept at 400°C for 4 hours in the air, washed, and dried to obtain Sn 0.8 Y 0.2 o 2-δ Nano stave.

Embodiment 3

[0042] Weigh 3.5053 grams of SnCl respectively 4 ·5H 2 O, 0.124 gram of ethylene glycol, 0.6404 gram of ammonium nitrate and 0.3728 gram of KCl are placed in a beaker with an appropriate volume of deionized water, heated and stirred to dissolve the reactant completely, continue heating, and when the solution is concentrated to nearly After the viscous state, put it into a microwave oven and heat until the self-propagating combustion reaction occurs. The combustion product is kept at 400°C in the air for 4 hours, washed and dried to obtain tin dioxide nanorods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com