Method for joint production of sulfuric acid and refined iron powder by mixed burning of ferrous sulfate and pyrite

A technology of ferrous sulfate and pyrite, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problem of low comprehensive utilization rate of ferrous sulfate waste residue, and reduce the consumption of pyrite resources in sulfuric acid production , Alleviate the pressure of railway transportation and protect the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

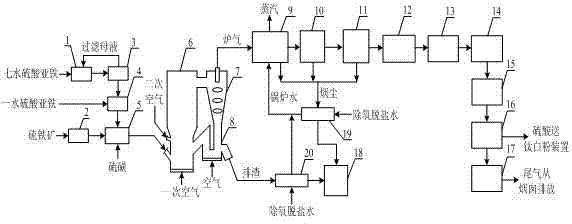

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] The present invention is described below using examples, but the present invention is not limited to these examples. In these examples: process ferrous sulfate heptahydrate (dry basis) according to the method of the present invention and contain following shown components: w (FeSO 4 ·7H 2 O) 93.17%, w (MgSO 4 ·7H 2 O) 3.32%, w (MnSO 4 ·5H 2 O) 1.26%, w [Al 2 (SO 4 ) 3 18H 2 O]0.41%, w (CaSO 4 2H 2 O) 0.19%, w (TiOSO 4 ) 0.15%, other water-insoluble substances ( w ) 1.50%.

[0031] According to the spent acid that the method for the present invention handles concentrates and separates out ferrous sulfate monohydrate (dry base) contains the following components: w (FeSO 4 ) 42.93%, w [Fe 2 (SO 4 ) 3 ]3.81%, w (MgSO 4 ) 16.66%, w (MnSO 4 ) 2.85%, w [Al 2 (SO 4 ) 3 ]2.43%, w (CaSO 4 ) 0.84%, w (TiO 2 ) 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com