Ballast water treatment plant for ocean-going vessel

A technology for ocean-going ships and treatment devices, which is applied in the field of ballast water treatment devices for ocean-going ships, can solve the problems of complicated piping systems and do not use them, and achieve the effects of reducing discharge time, convenient maintenance, and good economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

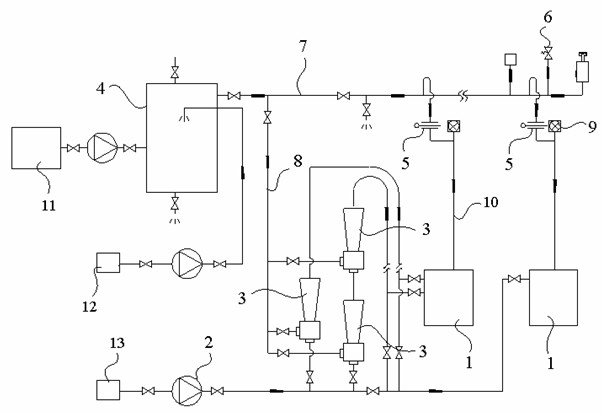

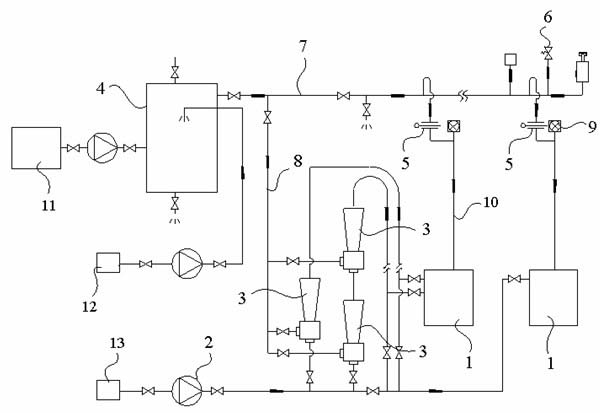

[0014] The present invention will be further explained below in conjunction with specific drawings.

[0015] Such as figure 1 As shown, the ballast water treatment device of an ocean-going ship includes a ballast tank 1 , a ballast pump 2 , a Venturi injector 3 and an inert gas generator 4 . The ballast pump 2 is arranged on the pipeline 14 that the ballast tank 1 communicates with the seawater 13 . There are 3 Venturi injectors 3, and 2 of them are connected in parallel with the other after being connected in series. The water outlet pipeline is connected with the ballast tank 1, and valves are arranged on each pipeline. The inert gas generator 4 communicates with the ballast tank 1 through the inert main pipe 7, and a double flange 5 is provided on the pipeline 10 communicating between the ballast tank 1 and the inert main pipe 7, and a ventilating pipe 7 is provided on the inert main pipe 7. Valve 6, vent valve 6 is a pneumatic vent valve. A magnetic breathable cap 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com