Preparation method for dissimilar metal plate loose lining

A technology of dissimilar metals and plates, which is applied in the field of preparation of loose linings of dissimilar metal plates, can solve problems such as the difficulty of explosive forming, and achieve the effects of low manufacturing cost, convenient operation, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Loose lining clad base material: copper-nickel alloy, material is HSn62-1; thickness is 2mm;

[0033] Steel plate base material: the material is Q345R, the thickness is 6mm;

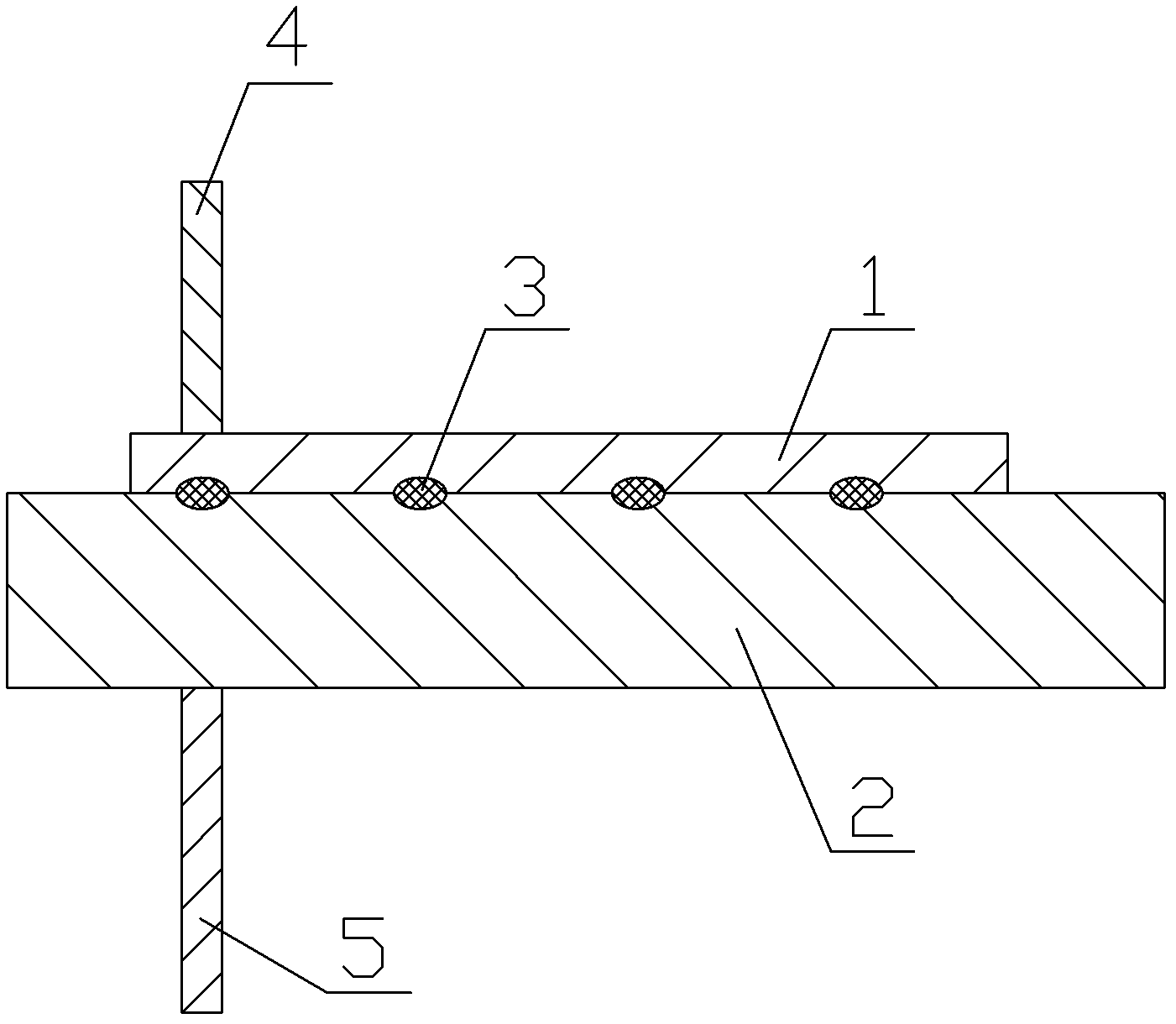

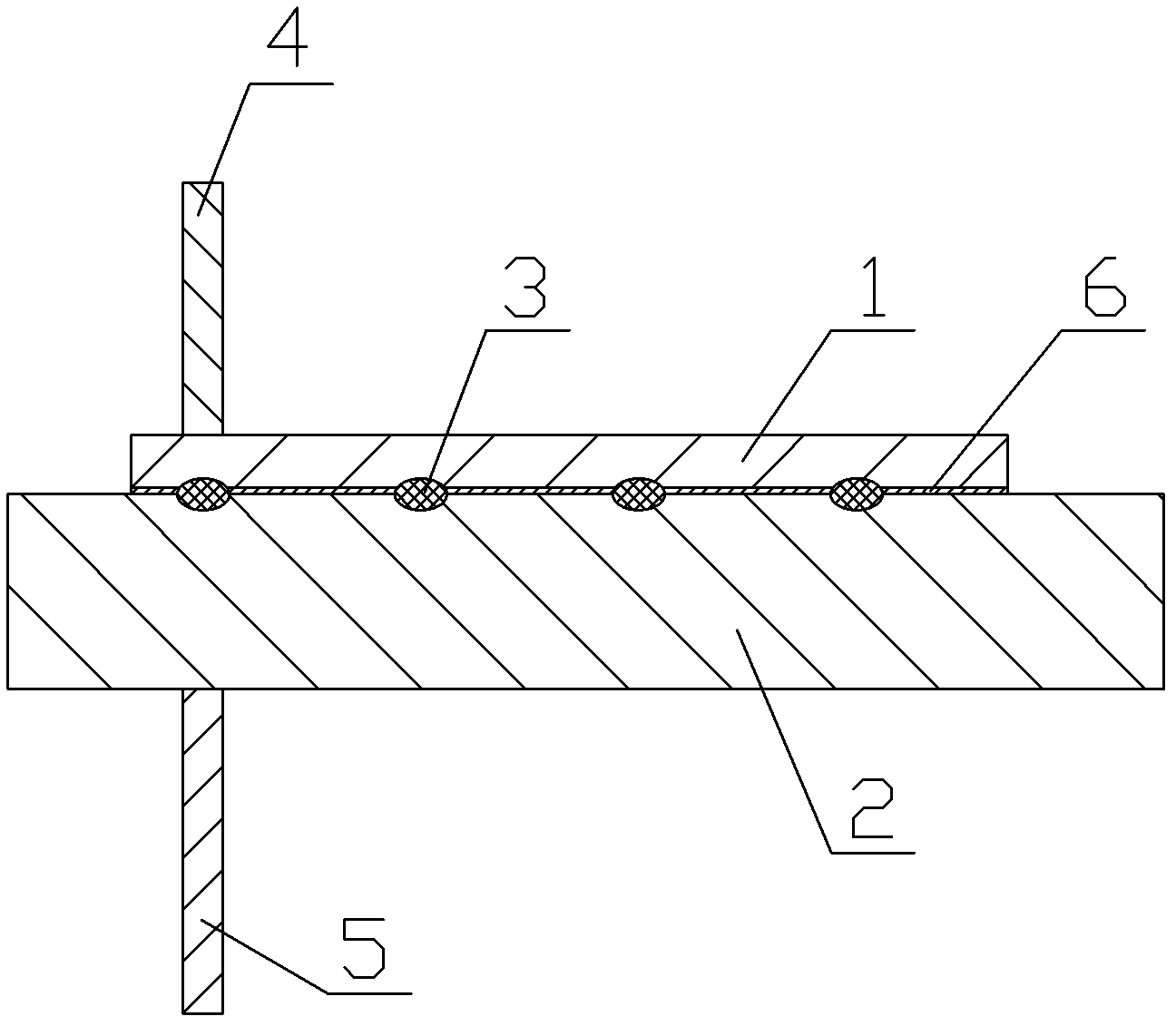

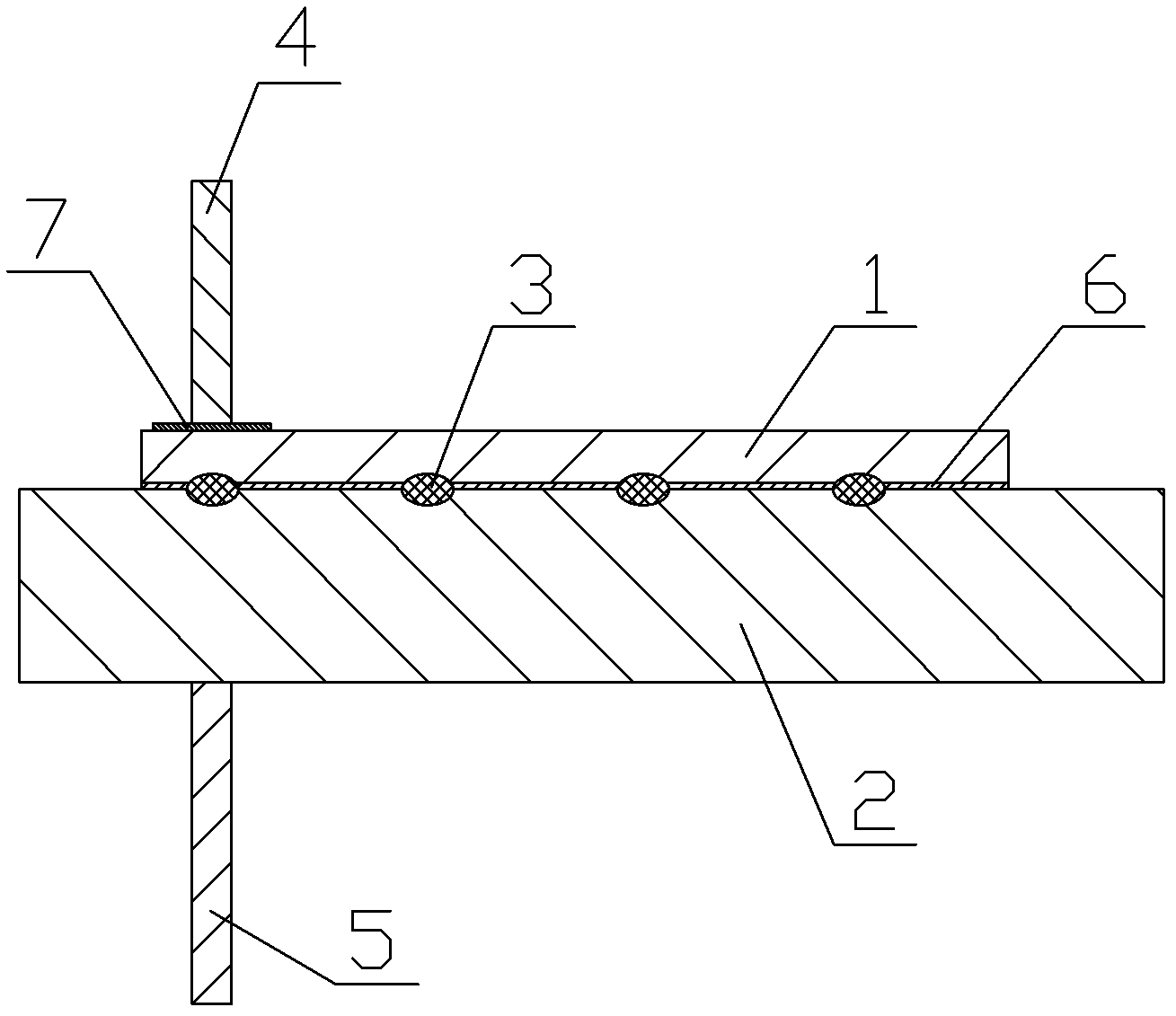

[0034] welded structure such as figure 1 ;

[0035] Step 1, using a grinding wheel to grind the weld area of the base metal 2 of the steel plate, and then polishing with a thousand impeller to remove the oxide film in the weld area;

[0036] Step 2: Use a thousand impeller to polish the weld area of the loose-lined clad base metal 1, and wipe the weld area within 50 mm with acetone or absolute ethanol;

[0037] Step 3. Align the weld area of the loose-lined and clad-layer base material 1 processed in step 2 with the weld area of the steel plate base material 2 after mechanical grinding and polishing in step 1, and use clamps to align the loose-lined and clad-layer base material Material 1 and steel plate base material 2 are fixed together;

[0038] Step 4. Place the loose-lined and cla...

Embodiment 2

[0041] This embodiment is the same as Embodiment 1, except that the thickness of the base material of the loose lining clad layer is 6 mm, and the thickness of the base material of the steel plate is 20 mm.

Embodiment 3

[0043] This embodiment is the same as Embodiment 1, except that the thickness of the base material of the loose lining clad layer is 0.8 mm, and the thickness of the base material of the steel plate is 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com