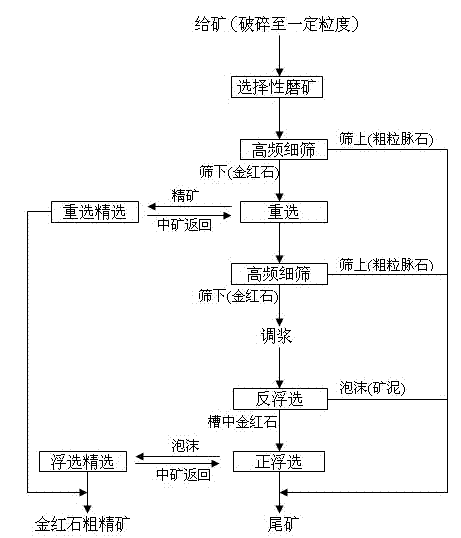

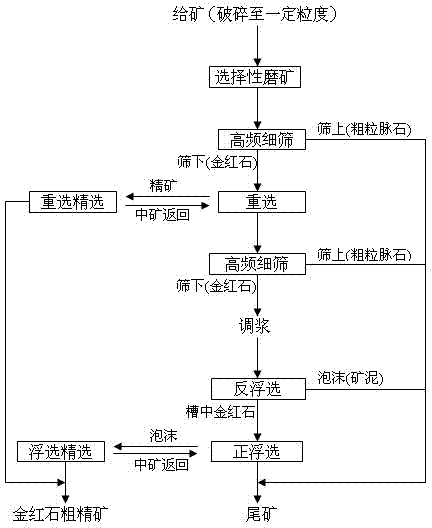

Rutile roughing technology consisting of selective ore grinding, coarse particle gravity separation and fine particle floatation

A selective and grinding technology, which is applied in the field of mineral processing engineering, can solve the problems of large rutile loss, large water consumption, and chemical consumption, so as to improve the flotation separation index, reduce the consumption of chemical agent, and improve the gravity selection index. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A rutile mine in Shaanxi contains rutile TiO 2 1.98%, the gangue minerals are mainly vermiculite, hydromica, hornblende, etc., and also contain a small amount of iron-containing minerals magnetite, hematite and clay minerals. The particle size of rutile intercalation is fine, generally ranging from 0.01 to 0.1mm, which belongs to fine-grained and micro-fine particle uneven intercalation. Most rutile is arranged in intermittent stripes and streaks in the form of monomers and aggregates along the slab direction of the ore. Some are mixed with vermiculite and hydromica to form agglomerates, and some are wrapped by hornblende and biotite. Due to the severe weathering of the raw ore, the raw ore is washed with double-layer vibrating screens (the upper sieve hole is 45mm, and the lower sieve hole is 6mm) and high-pressure water is used to wash the ore. mm, the returned sand and crushed products are combined into the grinding, the steel forging diameter is 40mm, the overflow ...

Embodiment 2

[0023] A rutile mine in Henan contains rutile TiO 2 2.09%, rutile intercalation particle size is fine, generally ranging from 0.01 to 0.2mm, belonging to fine-grained, uneven micro-grain intercalation, which is refractory rutile ore. The raw ore is crushed and screened to 12mm and fed into the ore grinding. The steel forging diameter of the grinding medium is 40mm. The grinding product is sieved by a high-frequency fine sieve with a sieve hole of 0.15mm. Containing rutile TiO 2 0.31%. The underscreen material is fed into the spiral chute for one coarse and three fines, and the medium ore is re-grinded and returned for re-election. The yield of the spiral chute re-selected coarse and concentrated ore is 1.45%, the grade is 49.80%, and the recovery rate is 34.52%. Gravity separation tailings are sent to the second high-frequency fine sieve for sieving, the sieve hole is 0.1mm, and the yield of tailings on the sieve is 23.14%, containing rutile TiO 2 0.28%. Dehydrate under th...

Embodiment 3

[0025] A rutile mine in Henan contains rutile TiO 2 2.10%, rutile intercalation particle size is fine, generally ranging from 0.01 to 0.2mm, belonging to fine grains, micro-fine grain uneven intercalation, and refractory rutile ore. The raw ore is crushed and screened to 12mm and fed into the ore grinding. The steel forging diameter of the grinding medium is 60mm. The grinding product is sieved by a high-frequency fine sieve with a sieve hole of 0.3mm. Containing rutile TiO 2 0.25%. The underscreen is fed into the spiral chute for one coarse and three fines, and the middle ore is re-grinded and returned for re-election. The yield rate of the spiral chute re-selected coarse and concentrated ore is 1.40%, the grade is 50.80%, and the recovery rate is 35.12%. Gravity separation tailings are sent to the second high-frequency fine sieve for sieving, the sieve hole is 0.09mm, and the yield of tailings on the sieve is 24.14%, containing rutile TiO 2 0.27%. Dehydrate under the sie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com