Preparation method of activated carbon adsorbent loaded with titanium dioxide

A technology of activated carbon adsorption and titanium dioxide, which is applied in the field of preparation of activated carbon and activated carbon adsorbent, can solve problems such as not found, and achieve the effects of simple operation, easy promotion of industrialization and marketization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

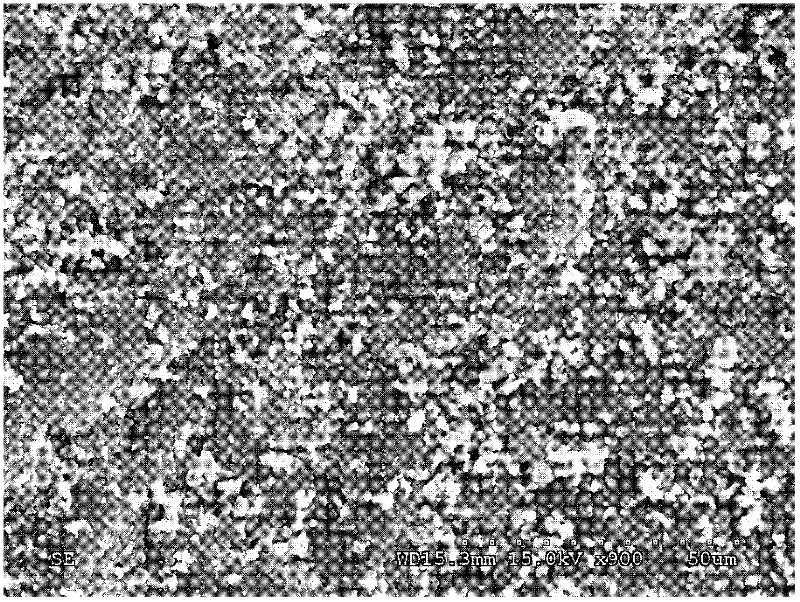

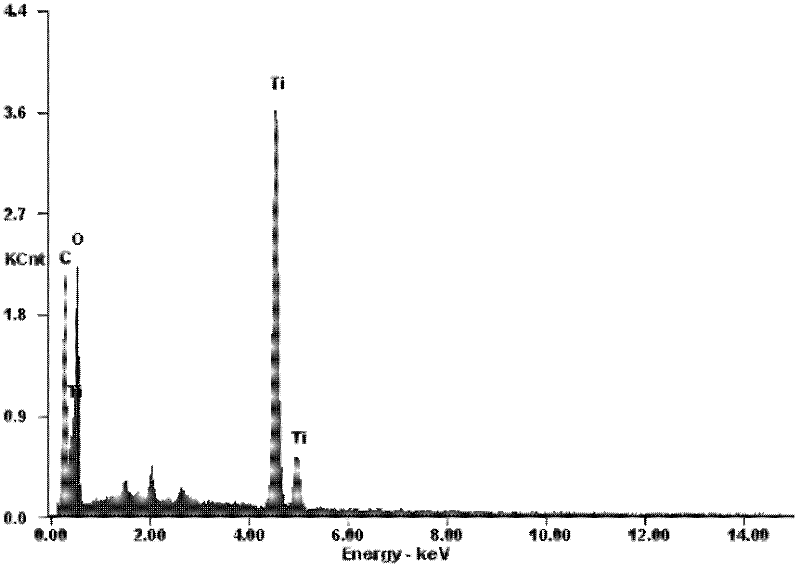

Image

Examples

Embodiment 1

[0023] (1) Screen the commercial activated carbon AC-1 before use, sieve through 10-20 meshes, place the obtained activated carbon in a beaker filled with deionized water twice the volume of activated carbon, and place it in an aqueous solution In a digitally controlled ultrasonic cleaner, ultrasonicate at room temperature for 1 hour to remove powder and oily substances in the activated carbon, wash with deionized water, filter with suction, and dry;

[0024] (2) Mix 33.7ml deionized water, 6.5ml concentrated HCl solution and 9.8ml TiCl 3 The solution was sequentially added to the polytetrafluoroethylene liner of the 100ml stainless steel reaction kettle, and configured as 0.5mol / L TiCl 3 - HCl solution;

[0025] (3) Add 20 g of granular activated carbon obtained in step (1) to the solution prepared in step (2), tighten the stainless steel reaction kettle, place it in an electric constant temperature blast drying oven for hydrothermal treatment, and treat it at 160 ° C for 24...

Embodiment 2

[0028] (1) Screen the commercial activated carbon AC-2 before use, sieve through 10-20 meshes, place the obtained activated carbon in a beaker filled with deionized water twice the volume of activated carbon, and place it in an aqueous solution In a digitally controlled ultrasonic cleaner, ultrasonicate at room temperature for 1.5 hours to remove powder and oily substances in activated carbon, wash with deionized water, filter with suction, and dry;

[0029] (2) Mix 33.7ml deionized water, 6.5ml concentrated HCl solution and 9.8ml TiCl 3 The solution was sequentially added to the polytetrafluoroethylene liner of the 100ml stainless steel reaction kettle, and configured as 0.5mol / L TiCl 3 - HCl solution;

[0030] (3) Add 20 g of granular activated carbon obtained in step (1) to the solution prepared in step (2), tighten the stainless steel reaction kettle, place it in an electric constant temperature blast drying oven for hydrothermal treatment, and treat it at 160 ° C for 24 ...

Embodiment 3

[0032] (1) Screen the commercial activated carbon AC-3 before use, sieve through 10-20 meshes, place the obtained activated carbon in a beaker filled with deionized water twice the volume of activated carbon, and place it in an aqueous solution In a digitally controlled ultrasonic cleaner, ultrasonicate at room temperature for 2 hours to remove powder and oily substances in the activated carbon, wash with deionized water, suction filter, and dry;

[0033] (2) Mix 33.7ml deionized water, 6.5ml concentrated HCl solution and 9.8ml TiCl 3 The solution was sequentially added to the polytetrafluoroethylene liner of the 100ml stainless steel reaction kettle, and configured as 0.5mol / L TiCl 3 - HCl solution;

[0034] (3) Add 20 g of granular activated carbon obtained in step (1) to the solution prepared in step (2), tighten the stainless steel reaction kettle, place it in an electric constant temperature blast drying oven for hydrothermal treatment, and treat it at 160 ° C for 24 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com