First-stage rutin extraction equipment

An extraction equipment and technology for rutin, applied in the field of first-level rutin extraction equipment, can solve the problems of low extraction rate, low degree of automation, low rutin purity, etc., and achieve improved extraction purity and extraction rate, high degree of automation, The effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

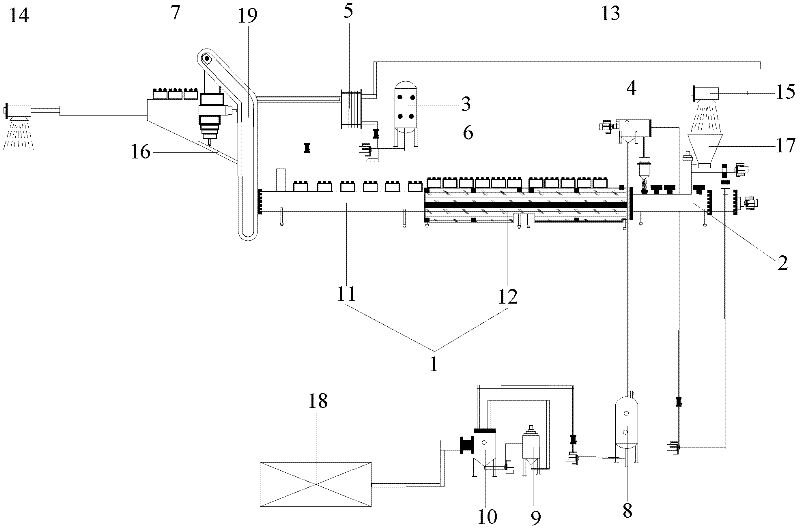

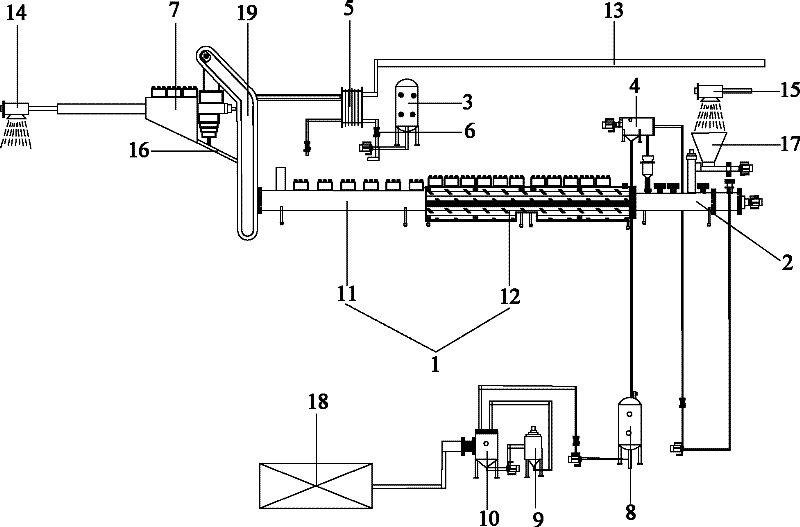

[0035] See figure 1 , which is a schematic structural view of the first stage rutin extraction equipment in the present invention.

[0036] The first-stage rutin extraction equipment provided by the present invention includes a screw propeller 2, a countercurrent ultrasonic extraction pipeline 1, a slag discharge mechanism, a rotary drum filter 4, an extraction liquid storage tank 8, a rotary disc filter 10, a spiral The propeller 2 is connected to the countercurrent ultrasonic extraction pipeline 1, the countercurrent ultrasonic extraction pipeline 1 is connected to the slag discharge mechanism, the countercurrent ultrasonic extraction pipeline 1 is connected to the rotary filter 4, and the rotary filter 4 is connected to the extraction liquid storage tank 8 , The extraction li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com