Preparation technology of novel gas chromatography detector

A preparation process and technology of gas chromatograph, which is applied in the field of preparation process of new gas chromatographic detectors, can solve the problems of unsuitable application in occasions with strict requirements for explosion protection, unsuitable for online applications, etc., and achieve excellent sensitivity, high yield, The effect of increasing the density of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

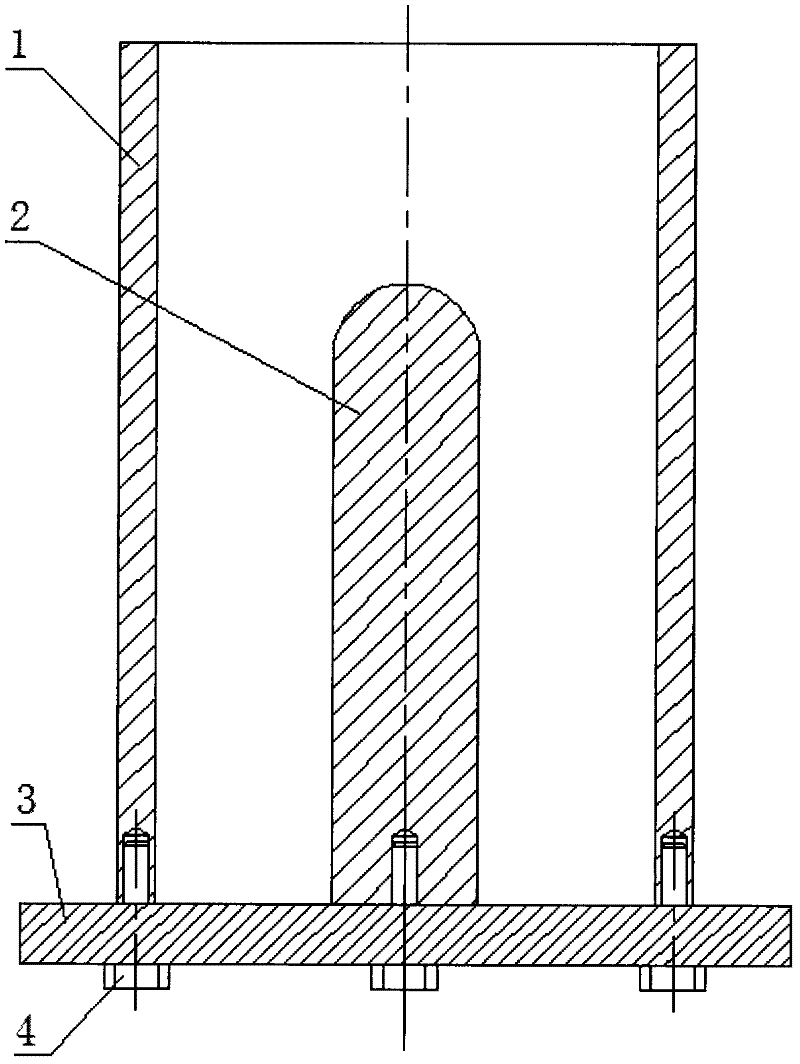

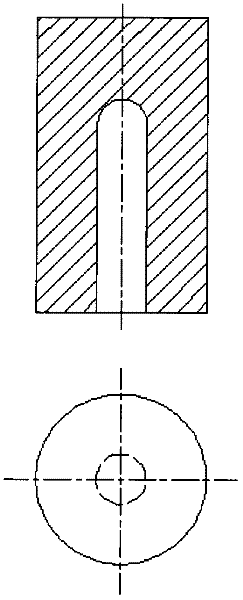

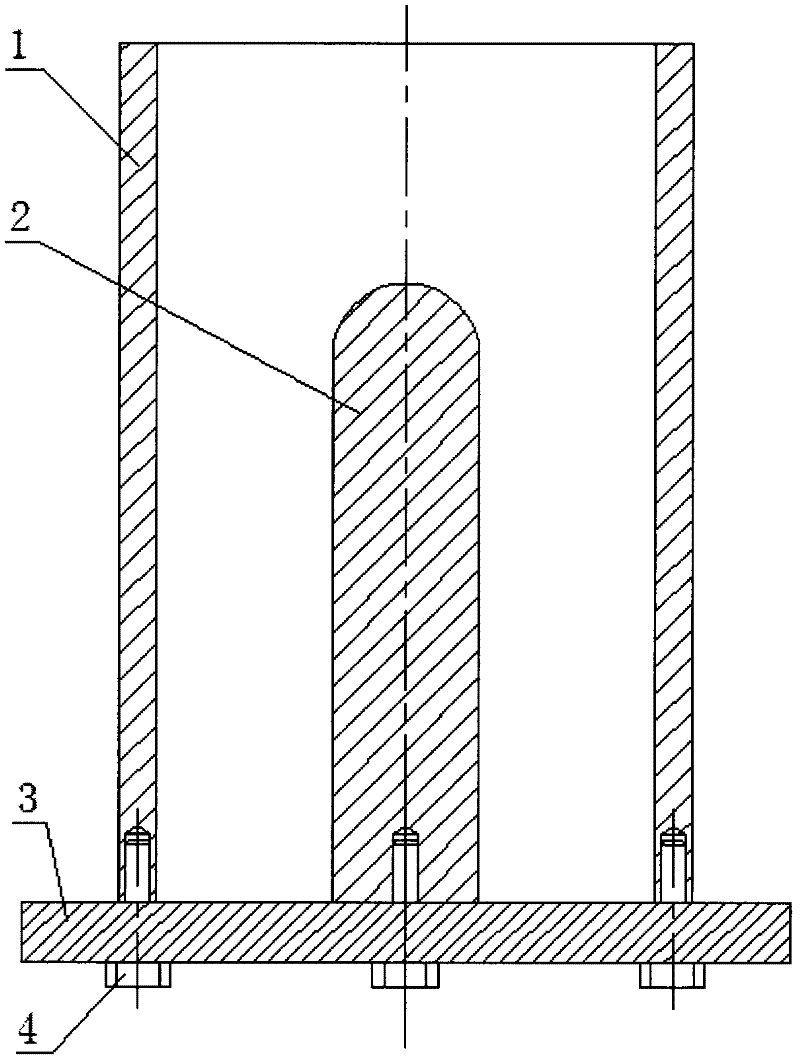

[0028] The raw material of the slurry is 3% molSc 2 o 3 and 8% mol Y 2 o 3 Stable ZrO 2Powder, the average particle size d(0.5) is 0.7μm, and gum arabic is added as a dispersant and binder, and distilled water is used as a solvent. When the volume fraction of the solid phase of the slurry is 18 vol%, and the amount of gum arabic added accounts for 3.0% of the weight of the dry material, it is ball milled in a ball mill for 30 minutes. Pour the slurry that has been sieved and vacuum defoamed into a gypsum mold, and pour out the remaining slurry after standing for 5.5 minutes. After demoulding, the green body is taken out, pre-sintered at 1200°C, trimmed after cooling, and then secondarily sintered at 1600°C to make a long tube detector base. Put the detector substrate into the HF solution and soak it, then clean it and dry it, use a clean and dry small brush to apply a uniform thin layer of the prepared platinum electrode slurry on the electrode part of the sensor substrat...

Embodiment 2

[0030] The raw materials and steps of slurry adjustment are the same as in Example 1. When the amount of gum arabic added accounted for 4% of the weight of the dry material, it was ball-milled in a ball mill for 50 minutes. The grouting time is the same as that of Example 1, and the pre-firing and sintering temperature are the same as that of Example 1. Platinum electrodes are sintered at 1200°C. The measured density is 5.716×10 3 Kg / m 3 , the metal particles on the surface were observed to increase and densify by scanning electron microscopy, and the number of micropores increased and the number decreased.

[0031] It shows that the increase of ball milling time can make the particle size of raw materials smaller. It shows that with the increase of electrode sintering temperature, the electrode metal grains grow gradually, which promotes the increase of the hole diameter on the electrode surface. Experiments show that the electrode sintering temperature is the best at (9...

Embodiment 3

[0033] The raw materials and steps of slurry adjustment are the same as in Example 1. The amount of gum arabic added, the ball milling time and the grouting time are the same as in Example 1. The calcining temperature is the same as in Example 1, but when the sintering temperature is 1400°C, the density of the detector substrate is 5.133×10 3 Kg / m 3 . It shows that the higher the sintering temperature, the greater the density of the detector matrix and the better the compactness, but it can fully meet the several application requirements described in the present invention at 1700 °C, and if the temperature continues to increase, over-burning will occur. And the high temperature has high requirements on the equipment, and the cost is also greatly increased.

[0034] The gypsum master mold of the present invention has a simple structure and is easy to adjust the length and inner diameter of the gypsum mold cavity so as to produce detector substrates of different sizes accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com