Electrolytic manganese solution containing new additive, and preparation method and application thereof

A preparation method, the technology of electrolytic manganese, applied in the direction of photography technology, instrument, photography auxiliary technology, etc., can solve the problems of no practical application, increase of operating cost, reduction of current density, etc., to achieve easy supplement and preparation, meet the needs of industrialization, capacitance The effect of density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

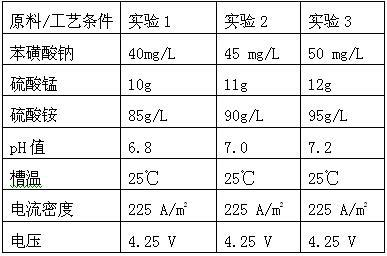

[0021] Sodium benzenesulfonate is used as the electrolytic manganese liquid additive product to prepare according to the following raw material ratio and method (g / L): sodium benzenesulfonate 25~90 mg / L, manganese sulfate concentration 7~35g / L, ammonium sulfate concentration 68~120g / L, adjust the pH value with ammonia water or sodium hydroxide to make the pH value = 5.0~8.3, and prepare selenium-free electrolytic manganese liquid products. Its best preparation raw materials and high-purity electrolytic manganese preparation method: sodium benzenesulfonate 40~45mg / L, manganese sulfate 11~12g / L, ammonium sulfate 80~85g / L, pH=7.0~7.2. The present invention involves using sodium benzenesulfonate as the electrolytic manganese liquid additive product and the high-purity electrolytic metal manganese product obtained by producing it in process control conditions, which can be widely used in the iron and steel industry, aluminum alloy industry, magnetic material industry, Aerospace ind...

Embodiment 2

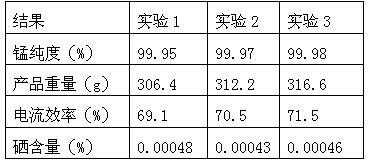

[0027] The composition of the selenium-free electrolytic manganese liquid product used is blended with other additives and the implementation process conditions are as follows:

[0028]

[0029] The result is as follows:

[0030]

[0031] It can be seen from the results of the examples that the addition of selenium dioxide (experiment 6), sodium sulfite (experiment 5) and ammonium sulfite (experiment 4) all reduced the purity of the electrolytic manganese product, and the addition of hydroquinone (experiment 7) and dodecylbenzene Sodium sulfonate (experiment 8) can obtain high-purity electrolytic manganese products, but the current efficiency is reduced.

Embodiment 3

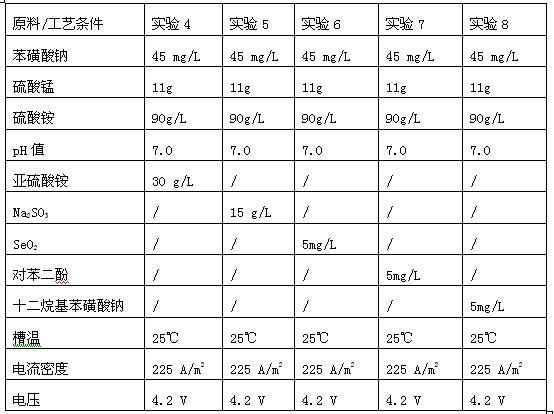

[0033] The selenium-free electrolytic manganese liquid product that the example of the present invention adopts forms and implements production process control condition as follows:

[0034]

[0035] The results obtained are as follows:

[0036]

[0037] It can be seen from the example results that the results of Experiment 11 are relatively ideal, with both high-purity electrolytic manganese products and high current efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com