Preparation method for grapheme thin film with local monoatomic layer

A single atomic layer graphite, multi-layer graphene technology, applied in coating, ion implantation plating, metal material coating process and other directions, to achieve the effect of improving the success rate, simple operation and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The multi-layer graphene film is suspended on the Cu grid of the carrier platform, and then the carrier platform is placed in a transmission electron microscope;

[0025] Multi-layer graphene film in 10 -6 Pa heated to 450°C in vacuum for 30 minutes, with a dose of 285A / cm 2 1. An electron beam with a beam diameter of 13nm was irradiated for 25 minutes to obtain a graphene film with a single atomic layer thickness. The relevant results are shown in the attached figure 1 and figure 2 .

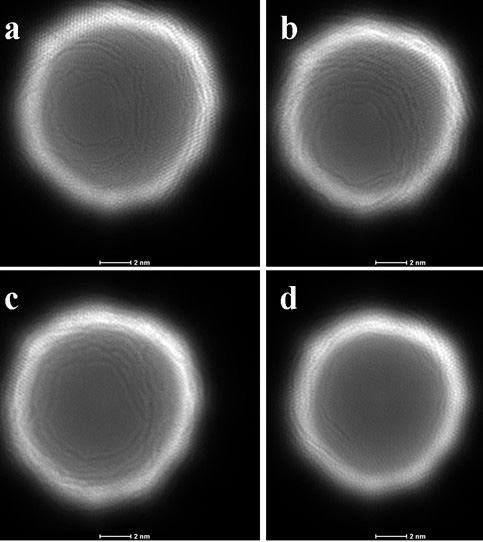

[0026] figure 1 It is a transmission electron micrograph of the thinning process of the graphene thin film obtained by the present invention; from a to b in the figure, it can be clearly seen that the area of single-layer graphene expands.

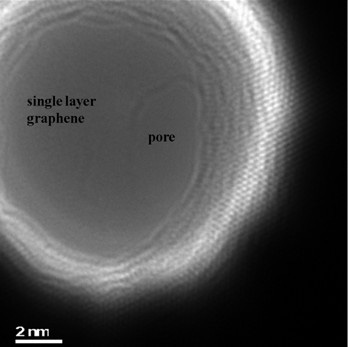

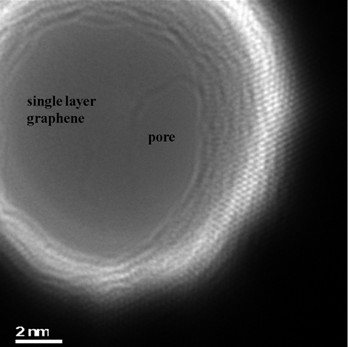

[0027] figure 2 It is a transmission electron microscope image of graphene with monoatomic layer thickness after thinning obtained by the present invention. Since the processing process is visible, the thickness of the graphene before th...

Embodiment 2

[0029] The multi-layer graphene film is suspended on the carrier platform SiN substrate, and then the carrier platform is placed in a transmission electron microscope;

[0030] Multi-layer graphene film in 10 -6 After heating to 1000° C. in Pa vacuum for 30 minutes, an electron beam with a beam diameter of 10 nm was irradiated for 5 minutes to obtain a graphene film with a single atomic layer thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com