Method for preparing large-area two-dimensional organic semiconductor crystalline film through two-step method

An organic semiconductor, large-area technology, which is applied in the field of two-step preparation of large-area two-dimensional organic semiconductor crystalline thin films, can solve the problems of cumbersome steps and poor film quality, and achieves low preparation cost, simple preparation steps, and high level of operation. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

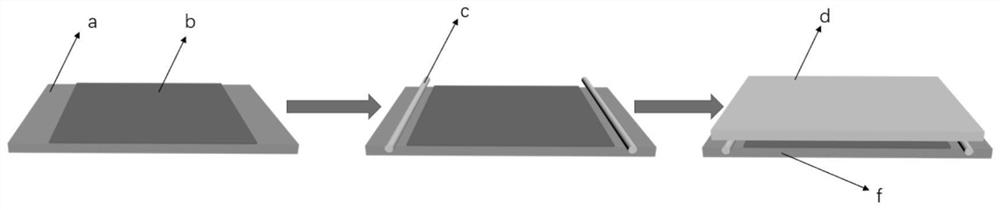

[0032] Such as figure 1 As shown, the rectangular cavity device of the present invention includes a lower substrate a, silver wires c placed on the left and right sides of the lower substrate a, and an upper substrate d placed on the silver wire, wherein the lower substrate a and the upper substrate d are placed oppositely, The silver wire c separates the lower substrate a from the upper substrate d to form a rectangular cavity f. The C8-BTBT raw material b is coated on the lower substrate a and crystallized in the rectangular cavity f.

[0033] The two-step method of the present invention prepares the method for large-area two-dimensional organic semiconductor crystalline film comprising the following steps:

[0034] (1) Coating raw materials for the lower substrate: the substrates used need to be ultrasonically cleaned with acetone, isopropanol, and deionized water for 15 minutes, and then dried with a nitrogen gun before use. Both the upper and lower substrates are grown wi...

Embodiment 2

[0043] The two-step method of the present invention prepares the method for large-area two-dimensional organic semiconductor crystalline film comprising the following steps:

[0044](1) Coating raw materials for the lower substrate: the substrates used need to be ultrasonically cleaned with acetone, isopropanol, and deionized water for 20 minutes, and then dried with a nitrogen gun before use. Both the upper and lower substrates are grown with 200 nanometers of SiO 2 SiO 2 / Si wafer; take about 0.05 mg C 8 - BTBT raw materials are evenly applied to the lower substrate, leaving silver wires on the edges of both sides, and there should be no lumps of raw materials, otherwise it will be easily adsorbed to the upper substrate when the substrate is covered, resulting in growth failure;

[0045] (2) Construct a rectangular growth cavity: Place 150 micron silver wires on both sides of the lower substrate coated with raw materials. After placing the silver wires, cover the upper subs...

Embodiment 3

[0051] The steps of growing and patterning a two-dimensional organic semiconductor crystalline film using a mask are as follows:

[0052] (1) Construct a growing rectangular cavity, and spread a layer of C evenly on the lower substrate 8 - BTBT raw material, then place a 10mm x 10mm reticle under the upper substrate so that the reticle is at C 8 - On the BTBT raw material layer, a mask such as Figure 9 ;

[0053] (2) Place the rectangular growth cavity on a heating platform for heating, the temperature is 250° C., and the heating time is controlled to 2 minutes. After the growth is over, the patterned film grows out with a small amount of bilayers, such as Figure 10 As shown, this will serve as a patterned master for the next step of recrystallization growth.

[0054] (3) if Figure 11 As shown, the patterned pre-crystallized master was heated and grown at 120 °C for 2 minutes, and the patterned master was heated and grown, and the quality of the monolayer film was impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com