Fracturing prepad fluid

A technology of pre-fluid and active agent, applied in drilling composition, chemical instruments and methods, etc., to achieve the effect of facilitating flowback, changing wettability, and reducing the viscosity of crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

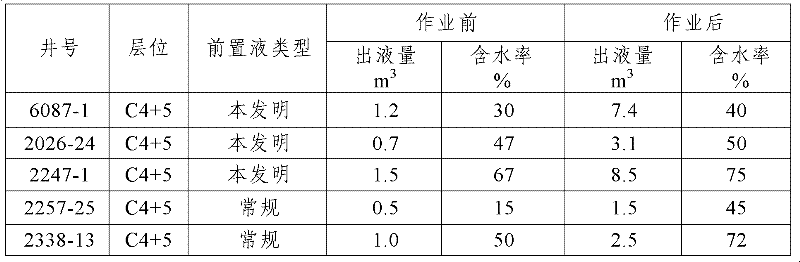

Examples

Embodiment 1

[0024] A fracturing prefluid in this embodiment is made by mixing the following raw materials in mass percentage: 1% of biological enzyme, 0.1% of clay stabilizer, 0.001% of fluorocarbon surfactant, 0.01% of wetting reversal agent, compound Active agent 0.01%, the balance is water; The clay stabilizer is anti-swelling agent COP-1, the fluorocarbon surfactant is fluorocarbon alkyl succinate sulfonate, and the wetting reversal agent is Organosilicon surfactant, the composite active agent is formed by mixing nonylphenol polyoxyethylene ether, sodium dodecylsulfonate and sodium lignosulfonate according to the mass ratio of 1:2:1; the biological enzyme The mass content of protein is 10%, the mass content of alcohol dehydrogenase is 35%, and the mass content of xylanase is 20%.

[0025] The preparation method of the fracturing prefluid of this embodiment is as follows: after mixing the raw materials in proportion, they can be stirred evenly.

[0026] The fracturing pad in this embo...

Embodiment 2

[0028] This embodiment is the same as Example 1, except that the clay stabilizer used is tetramethylammonium chloride, or NH 4 Cl and / or KCl; the fluorocarbon surfactant used is polyether quaternary ammonium salt cationic fluorocarbon surfactant or N,N-dihydroxyethyl perfluoroalkylamide; the wetting reversal agent used is C 12 -C 16 Alkyltrimethylammonium chloride; the complex active agent used is mixed with alkylphenol polyoxyethylene ethers, petroleum sulfonates and modified lignin according to the mass ratio of 1:2 to 4:1, wherein the alkane The base phenol polyoxyethylene ether is octylphenol polyoxyethylene ether, the petroleum sulfonate is sodium dodecylsulfonate or sodium dodecylbenzenesulfonate, and the modified lignin is sodium lignosulfonate or Potassium lignosulfonate.

Embodiment 3

[0030] A fracturing pre-fluid in this embodiment is prepared by mixing the following raw materials in mass percentage: biological enzyme 10%, clay stabilizer 1%, fluorocarbon surfactant 0.1%, wetting reversal agent 0.5%, compound Active agent 1%, balance is water; The clay stabilizer is NH 4 Cl and KCl, the fluorocarbon surfactant is a polyether quaternary ammonium salt cationic fluorocarbon surfactant, the wetting reversal agent is dodecyltrimethylammonium chloride, and the composite active agent It is formed by mixing nonylphenol polyoxyethylene ether, sodium dodecylbenzenesulfonate and potassium lignosulfonate according to the mass ratio of 1:4:1; the mass content of protein in the biological enzyme is 25%, ethanol The mass content of dehydrogenase is 25%, and the mass content of xylanase is 10%.

[0031] The preparation method of the fracturing prefluid of this embodiment is as follows: after mixing the raw materials in proportion, they can be stirred evenly.

[0032] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com