Environmentally friendly, high and low temperature resistant, oil resistant, wear resistant and fire retardant rubber plastic composition

A composition, rubber and plastic technology, applied in the field of rafter plastic composition, can solve the problems of poor wear resistance and high temperature resistance, unfavorable environment, unable to meet the requirements of long-term high temperature oil immersion performance, etc., and achieve good flame retardancy, wear resistance, etc. Excellent performance and color tunable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

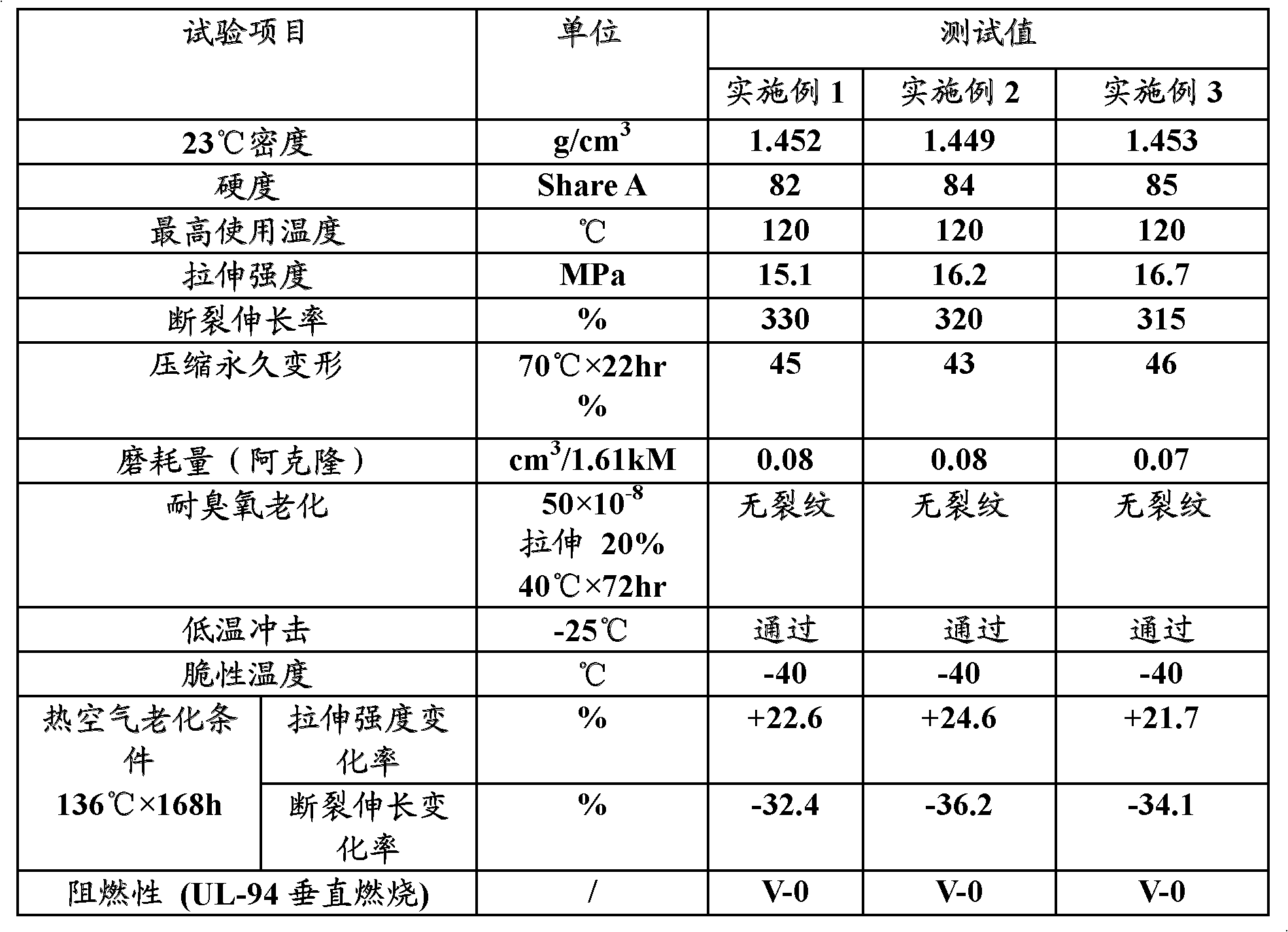

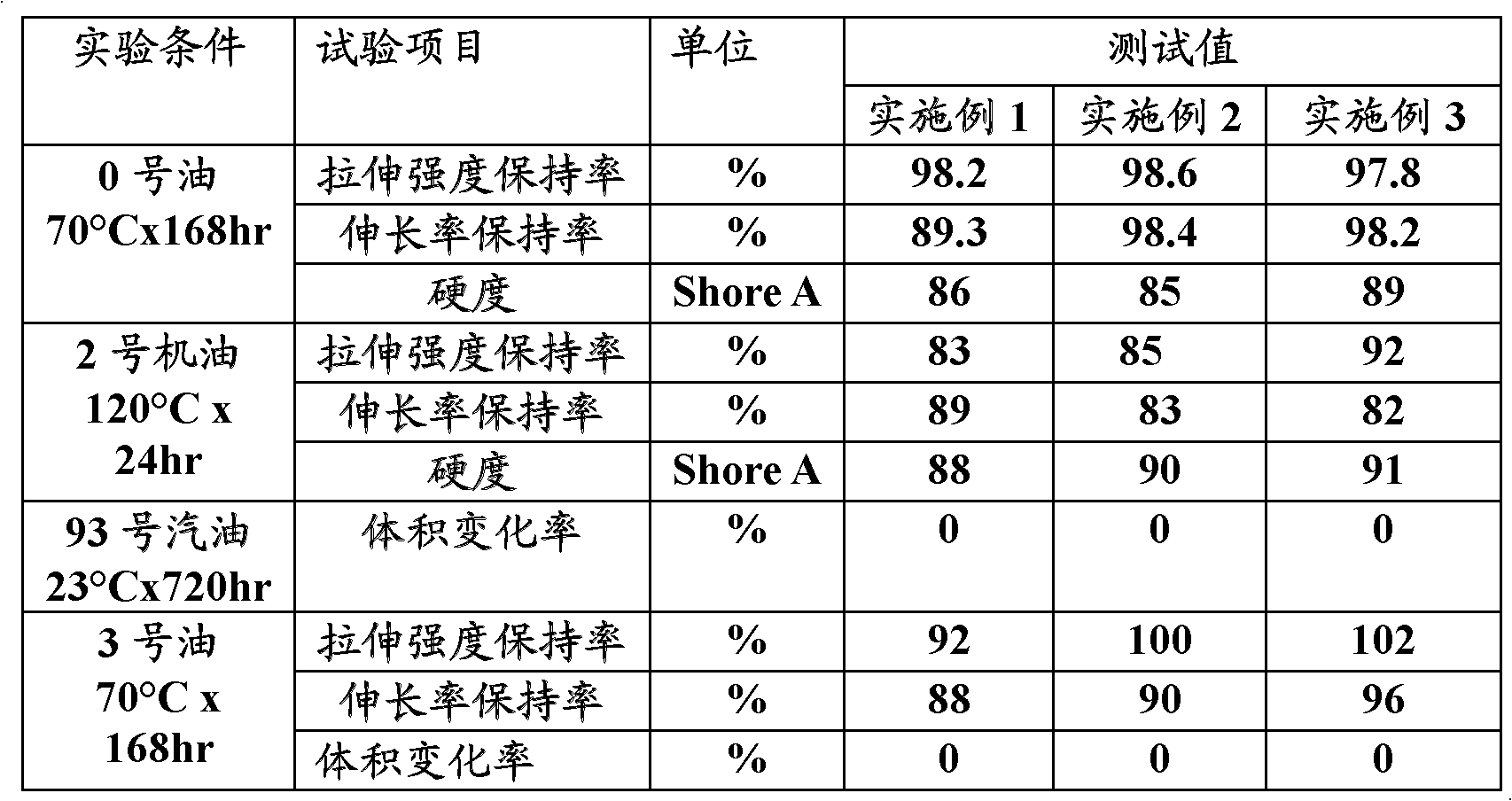

Embodiment 1

[0022] The present embodiment provides a kind of rubber-plastic composition, and its preparation method is as follows:

[0023] (1), prepare NBR powder: take by weight 100 parts of NBR with acrylonitrile content of 35wt%, 0.2 part of sulfur, 1.0 part of antioxidant 4010NA, 1.0 part of activator stearic acid, 0.5 part of vulcanization accelerator TMTD. Put it into the internal mixer for mixing and grinding, and add 1.03 parts of release agent PVC resin after discharging, of which: the internal mixer is 50 liters, the mixing and grinding temperature, the control temperature does not exceed 170 ° C, and the mixing time is 10 minutes ;

[0024] (2) Preparation of pre-plasticized PVC powder: Weigh PVC resin K: 65100 parts, add to a high-speed mixer, add 10 parts of plasticizer DIDP, 2.0 parts of calcium zinc stabilizer, 10100.3 parts of antioxidant, knead to 135 ° C, The material is discharged for use, wherein the high-speed mixer refers to a 100-liter stirring mixer, which operat...

Embodiment 2

[0028] The present embodiment provides a kind of rubber-plastic composition, and its composition is as follows: 45 parts of NBR powder, 35 parts of premolded PVC powder, 10 parts of PA (copolymerized by nylon 6,66,1010 by mass ratio 70:20:10) , 10 parts of magnesium hydroxide, 10 parts of antimony trioxide, 0.5 parts of ACR40 and 0.5 parts of oxidized polyethylene wax. The weight ratio of the NBR powder is: NBR 96% with acrylonitrile content of 35wt%, vulcanizing agent sulfur 0.3%, activator stearic acid 1%, anti-aging agent 4010NA 1%, vulcanization accelerator TMTD 0.7% and release agent 1% PVC resin; the composition weight ratio of the pre-molded PVC powder is: PVC resin K: 6583.75%, antioxidant 10100.34%, calcium zinc stabilizer 3.35% and plasticizer DIDP 12.56%.

[0029] The preparation method of the rubber-plastic composition of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0031]The present embodiment provides a rubber-plastic composition, its composition is as follows: 50 parts of NBR powder, 30 parts of premolded PVC powder, 15 parts of PA (copolymerized by nylon 6,66,1010 in a mass ratio of 70:20:10) , 15 parts of magnesium hydroxide, 5 parts of antimony trioxide, 0.5 parts of ACR40 and 0.5 parts of oxidized polyethylene wax. Wherein the composition weight ratio of NBR powder is: the NBR 95.75% that acrylonitrile content is 35wt%, vulcanizing agent sulfur 0.38%, activator stearic acid 0.956%, antioxidant 4010NA 0.957%, vulcanization accelerator TMTD0.957% and isolation Agent PVC resin 1%. The composition weight ratio of the preplasticized PVC powder is: PVC resin K: 6579%, antioxidant 10100.5%, calcium zinc stabilizer 6.3% and plasticized DIDP 14.2%.

[0032] The preparation method of the rubber-plastic composition of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com