Soluble metal salt recovery and wastewater purification device and method thereof

A waste water purification and metal salt technology, which is applied in chemical instruments and methods, separation methods, multi-stage water/sewage treatment, etc., can solve the problem that the amount of treated water cannot be infinitely enlarged, so as to improve the utilization rate of resources, increase the scope of application, The effect of resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

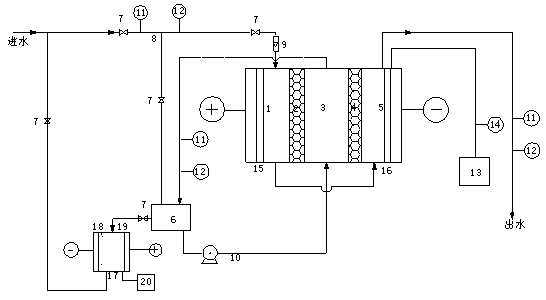

[0029] use figure 1 Shown is a device for recovering waste soluble metal salts and purifying waste water. The anode is a titanium mesh electrode coated with ruthenium, and the cathode is a stainless steel mesh electrode. The anion and cation exchange resins are respectively D201 macroporous strongly basic styrene-based hydrogen-oxygen resin and D001 macroporous styrene-based hydrogen-type resin. The size of the pool is 0.10864m 3 (1.94*0.4*0.14), the thickness of the resin wall is 0.14m. The raw water is the cleaning water of the plated parts discharged from the copper plating production line of the electroplating plant, which contains Cu 2+ About 50mg / L, pH value is about 6; 65V voltage is applied to both ends of the device electrodes; under this operating condition, the raw water treatment capacity is 0.25m 3 / min, Cu in fresh water 2+ The concentration is lower than 0.05mg / L, the current efficiency reaches about 40%, the Cu in concentrated water 2+ After about 10 hou...

Embodiment 2

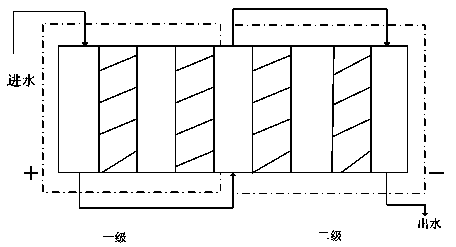

[0031] In embodiment 2, adopt two groups of devices to process in series containing Cu 2+ 100mg / L ( figure 2 ), the deionization principle and operation steps of the devices at all levels are the same as those in Example 1. Apply a voltage of 60V to both ends of the electrode of the device, and run stably and continuously for 480 hours. The concentration of the effluent after the first stage is about 5-10mg / L, and the concentration of the effluent after the second stage is about 0.2-1.0mg / L. The total removal rate can be as high as 99%-99.8%.

Embodiment 3

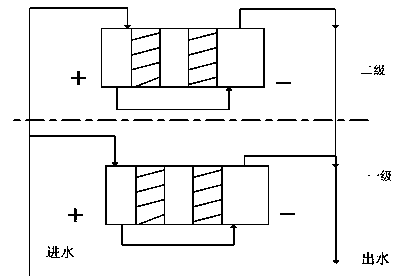

[0033] In embodiment 3, two groups of single-stage devices in embodiment 1 are adopted to process the raw water in parallel to be the plated piece cleaning water discharged from the copper plating production line of the electroplating plant ( image 3 ), which contains Cu 2+ About 50mg / L, pH value about 6; 65V voltage is applied to both ends of the device electrodes; under this operating condition, the raw water treatment capacity is at least doubled to 0.8-0.5m after continuous operation for a week 3 / min, the removal rate of ions can reach more than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com