Composite nano-zinc oxide material and its preparation method

A nano-zinc oxide, morphological technology, applied in zinc oxide/zinc hydroxide, nanotechnology and other directions, can solve the problems of improvement, low field enhancement factor, unfavorable field emission performance, etc., and achieves simple preparation process, good repeatability, improved Effects of Field Emission Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The ratios mentioned below are molar ratios. Zn(NO 3 ) 2 ·6H 2 O: F127=250:1, Zn(NO 3 ) 2 ·6H 2 O: HMT = 1: 1, Zn(NO 3 ) 2 ·6H 2 O, F127, and HMT were placed in deionized water and stirred until they were evenly mixed; the FTO glass substrate coated with ZnO seed crystals (film thickness 200nm) was suspended in the above solution upside down; the reaction temperature was controlled at 95°C, and the growth time was 8h; After taking out the sample, wash it with deionized water and absolute ethanol respectively, and dry it at 60°C; put the product in a muffle furnace, raise the temperature to 450°C at a rate of 1°C / min, and keep it for 30min.

Embodiment 2

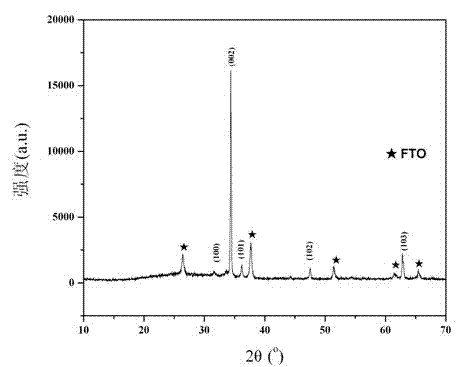

[0028] Zn(NO 3 ) 2 ·6H 2 O: F127=10:1, Zn(NO 3 ) 2 ·6H 2 O: HMT = 1: 1, put the above three substances into deionized water and stir until they are evenly mixed; invert and suspend the FTO glass substrate coated with ZnO seed crystals (the film thickness is 200nm) in the above solution; control the reaction The temperature was 95°C, and the growth time was 16 hours; the samples were taken out and rinsed with deionized water and absolute ethanol respectively, and dried at 60°C; the product was placed in a muffle furnace, and the temperature was raised to 450°C at a rate of 1°C / min. Keep warm for 30min. The XRD photo of the product is as figure 1 As shown, the electron microscope photos are as figure 2 shown. This product can significantly improve the field enhancement factor, such as image 3 shown.

Embodiment

[0030] Zn(NO 3 ) 2 ·6H 2 O: F127=5:1, Zn(NO 3 ) 2 ·6H 2 O: HMT = 1: 1, put the three substances into deionized water and stir until they are evenly mixed; put the FTO glass substrate coated with ZnO seed crystals (the film thickness is 200nm) upside down and suspend in the above solution; control the reaction temperature The temperature is 105°C, and the growth time is 24h; after taking out the sample, rinse it with deionized water and absolute ethanol, and dry it at 60°C; put the product in a muffle furnace, raise the temperature to 450°C at a rate of 2°C / min, and keep it warm 60min.

[0031] Example 4

[0032] Zn(NO 3 ) 2 ·6H 2 O: F127=10:1, Zn(NO 3 ) 2 ·6H 2 O: HMT = 1: 2, put the above three substances into deionized water and stir until they are evenly mixed; invert and suspend the FTO glass substrate coated with ZnO seed crystal (coating film thickness is 200nm) in the above solution; control the reaction The temperature was 95°C, and the growth time was 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com