Adhesive agent and adhesive sheet

A technology of adhesives and methyl, applied in the direction of adhesive types, ester copolymer adhesives, adhesives, etc., can solve problems such as discoloration, defects at the interface between the resin board and the adhesive layer, and changes in adhesion , to achieve small changes in optical properties, shorten the stabilization period, and not easily change color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0163] Acrylic copolymer (2EHA / In 100 parts by mass of CHA / HEA / DMAEA=59.5 / 40 / 0.3 / 0.2, weight average molecular weight of 600,000), a crosslinking agent (manufactured by Nippon Polyurethane Co., Ltd., toluene diisocyanate crosslinking agent, trade name "CORONATE L ", solid content 75%) 0.5 parts by mass (relative to 100 parts by mass of solid content of acrylic copolymer, its solid content is 0.375 mass parts), diluted with methyl ethyl ketone, and made an adhesive with a non-volatile content concentration of 30%. agent coating solution.

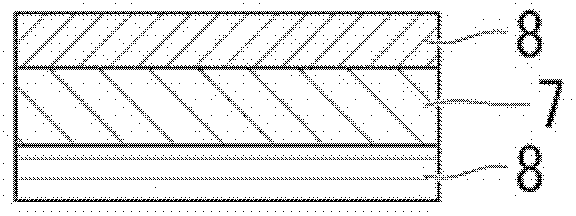

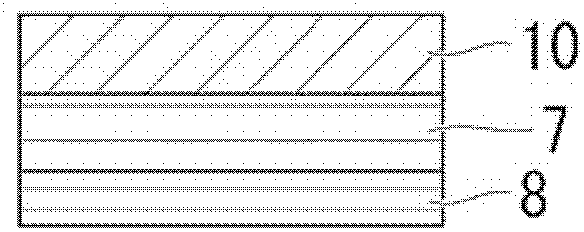

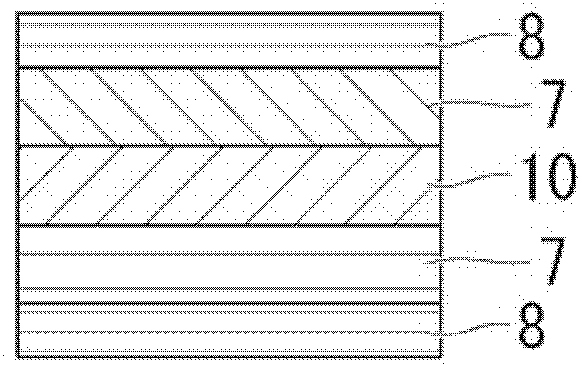

[0164] Apply this adhesive coating solution on the release-treated surface of a heavy-duty release film (manufactured by Lintec Corporation, trade name "SP-PET381031H", film thickness 38 μm) by the doctor blade coating method, and make the thickness after drying 25 μm, and dried at 90° C. for about 1 minute to form an adhesive layer.

[0165] The release-treated surface of a light-release sheet (manufactured by Lintec Corporation, trade na...

Embodiment 2

[0168] Except using 2EHA / CHA / HEA / DMAEA=44.5 / 55 / 0.3 / 0.2, and the weight-average molecular weight is 800,000 acrylic copolymers, similar to Example 1, made a double-sided pressure-sensitive adhesive sheet without a matrix material and Single-sided adhesive sheet with base material.

Embodiment 3

[0170] Except using 2EHA / CHA / HEA / DMAEA=69.5 / 30 / 0.3 / 0.2, and the weight-average molecular weight is 800,000 acrylic copolymer, similar to Example 1, made a double-sided pressure-sensitive adhesive sheet without matrix material and Single-sided adhesive sheet with base material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com