Piezoelectric vibrating piece and piezoelectric vibrator

A piezoelectric vibrating piece and piezoelectric vibrator technology, which are applied in the manufacturing/assembly of piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, and piezoelectric/electrostrictive devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0119] Experimental examples are shown below, and the present invention will be described in more detail. In addition, the present invention is not limited at all by the following experimental examples.

[0120] 5.1. The structure of the piezoelectric vibrating piece

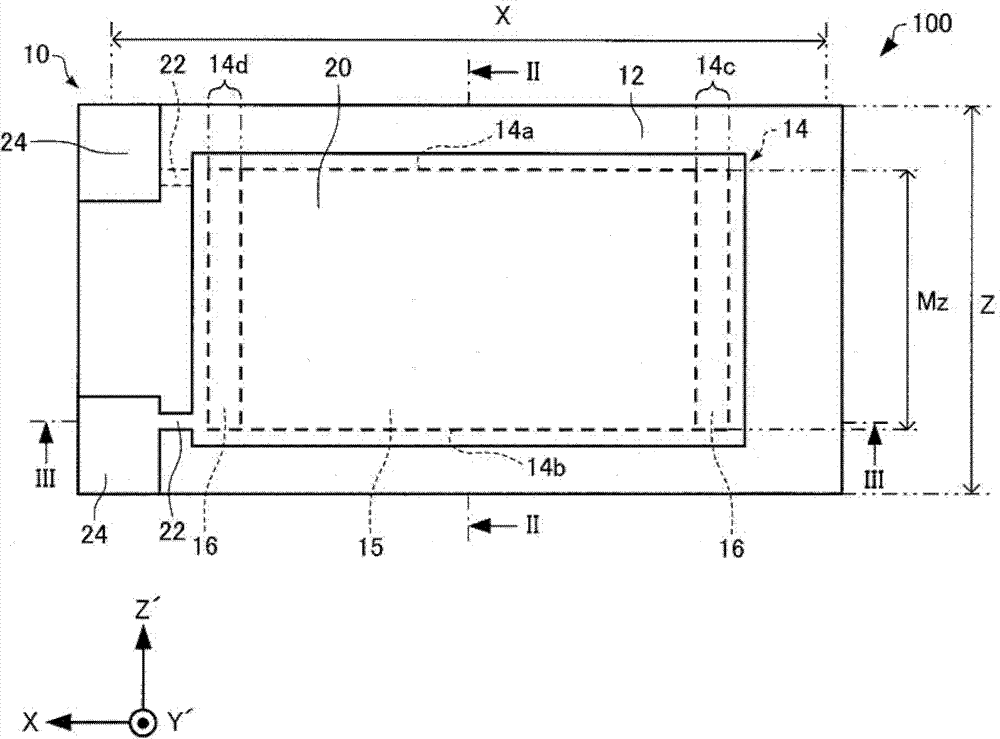

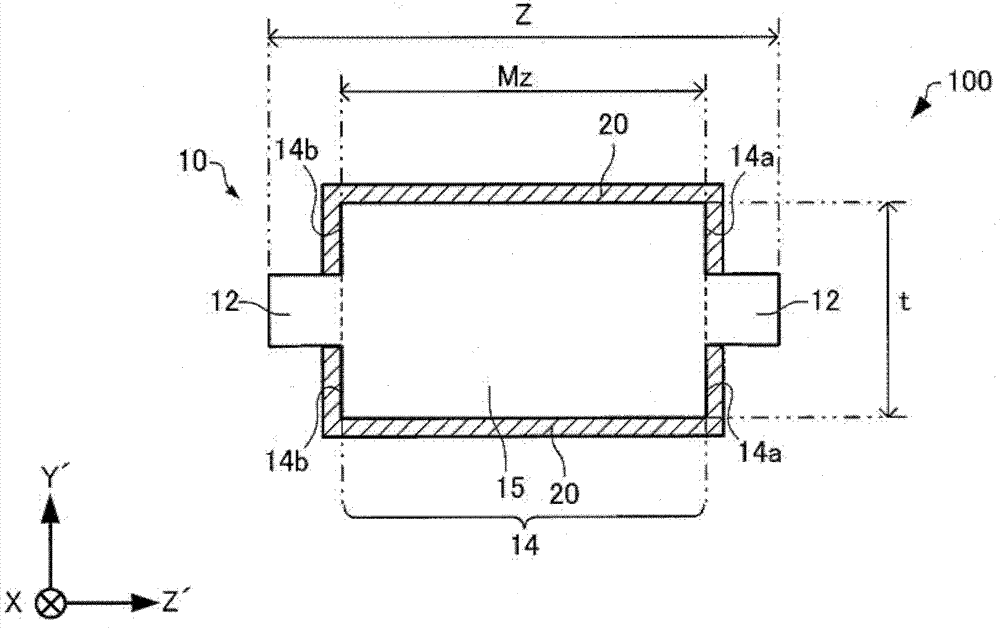

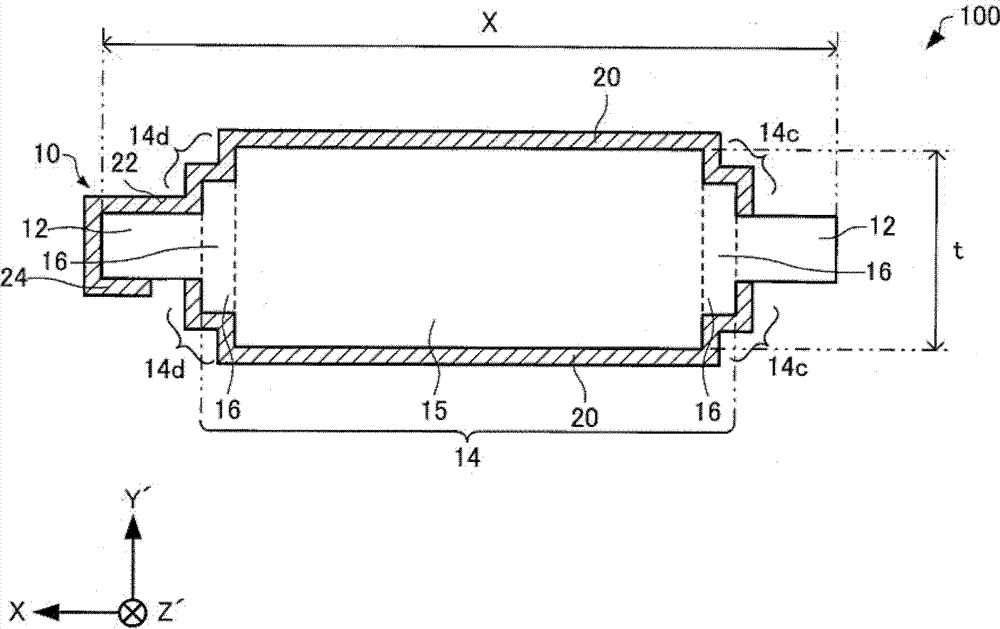

[0121] As Example 1, using Figure 1 to Figure 3 The shown piezoelectric vibrating piece 100 has a two-stage mesa structure. In Example 1, the AT-cut crystal substrate 101 was processed by wet etching using a solution containing hydrofluoric acid to form the piezoelectric substrate 10 having the peripheral portion 12 and the excitation portion 14 . The piezoelectric substrate 10 is formed point-symmetrically with respect to a point (not shown) serving as a center of symmetry. The thickness t of the excitation part 14 (first part 15) was set to 0.065 mm, and the vibration frequency was set to 24 MHz. In addition, the dimension X of the long side of the piezoelectric substrate 10 is set to 1.1 mm (that is, the X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com