Tuning-fork type quartz-crystal vibrating pieces and quartz-crystal devices

A vibrating piece and tuning fork type technology, which is applied in the field of tuning fork type crystal vibrating piece and crystal device, can solve the problem of thickening and other problems, and achieve the effect of low CI value and small wiring impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0025]

[0026] Hereinafter, various embodiments of the present invention will be described with reference to the drawings.

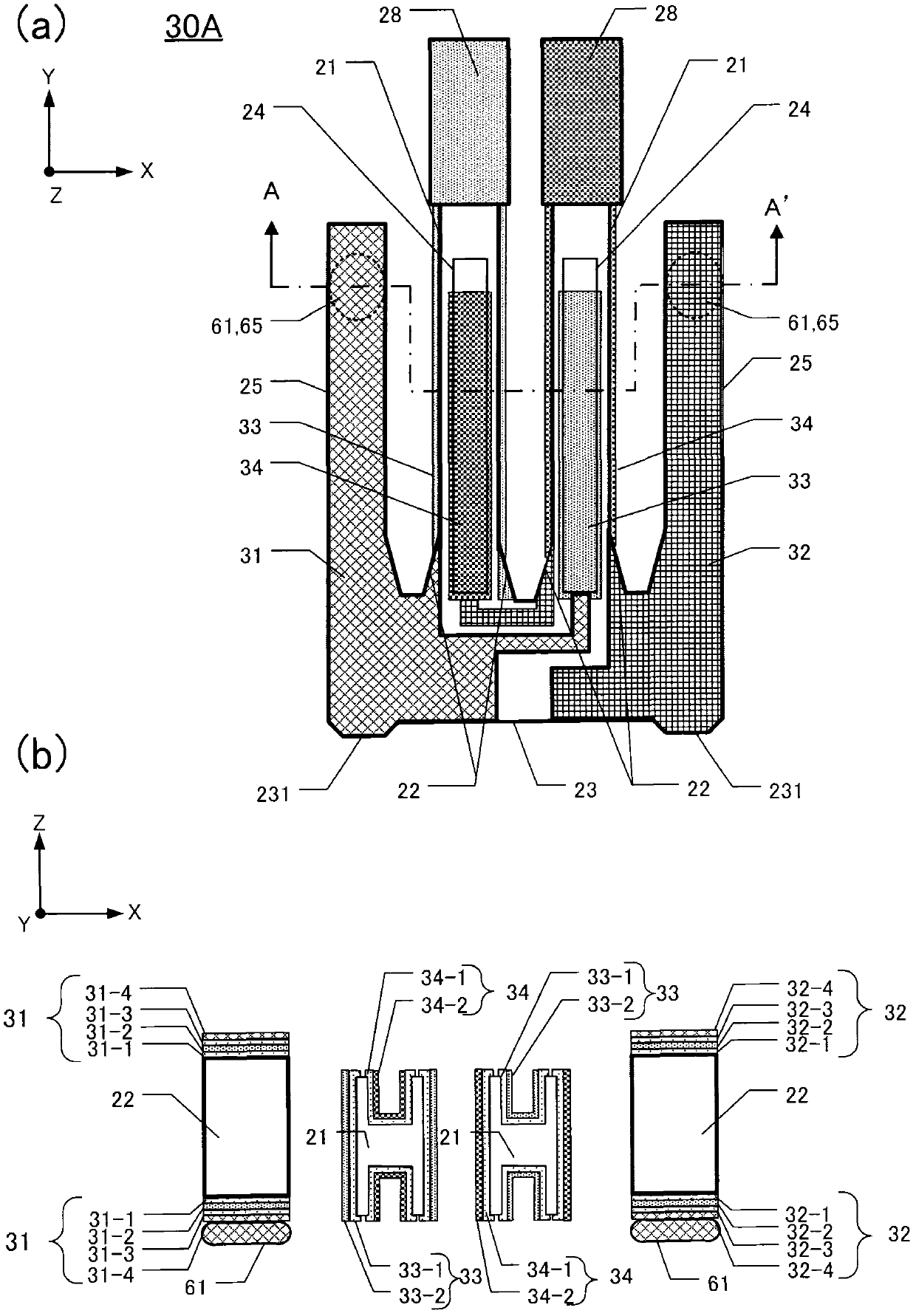

[0027] In the following embodiments, the extending direction of the vibrating arm is defined as the Y-axis direction, the arm width direction of the vibrating arm is defined as the X-axis direction, and the direction perpendicular to the X-axis and Y-axis direction is defined as the Z-axis direction.

[0028] (Formation of the first tuning fork type crystal vibrating piece 30A)

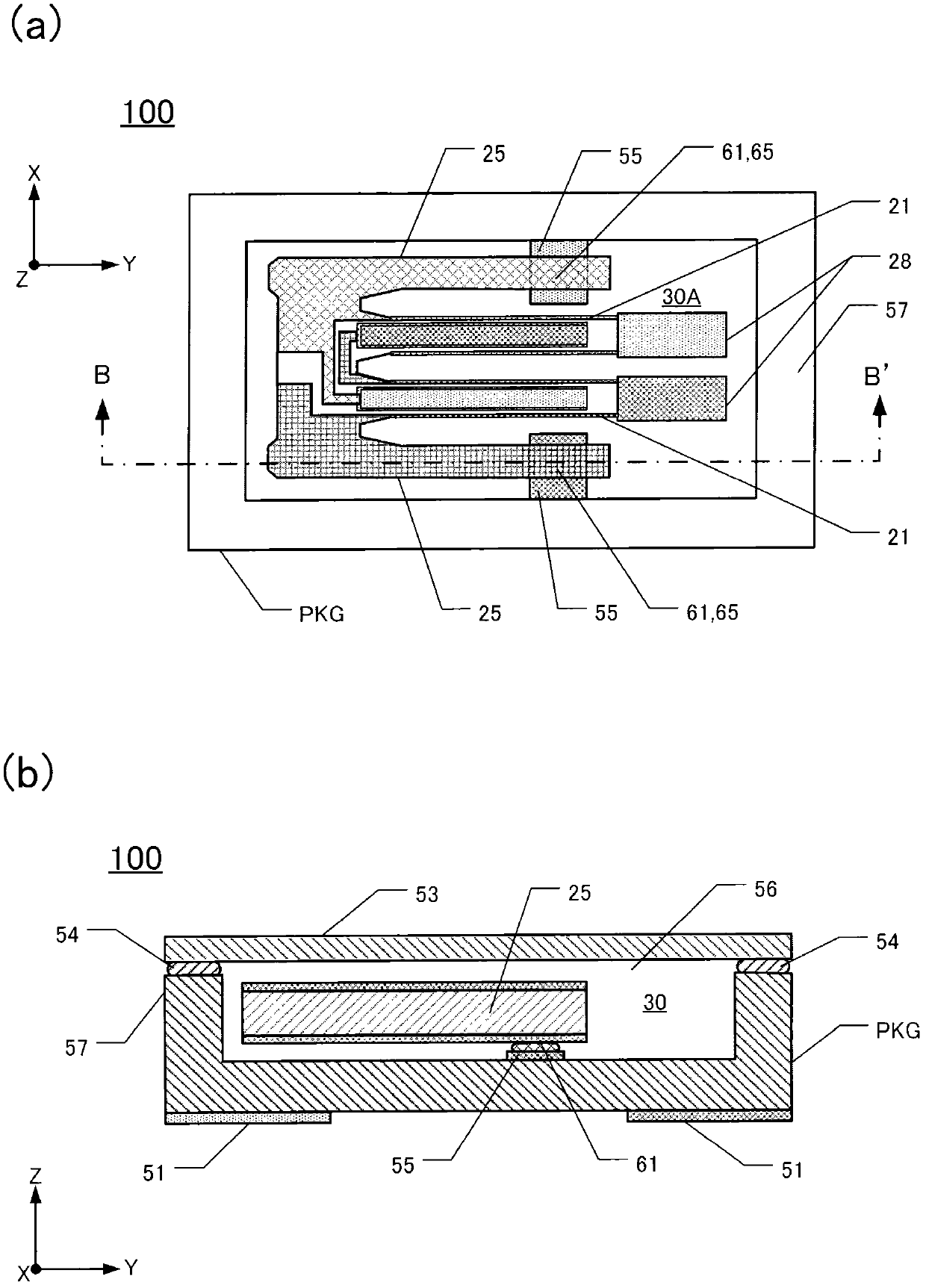

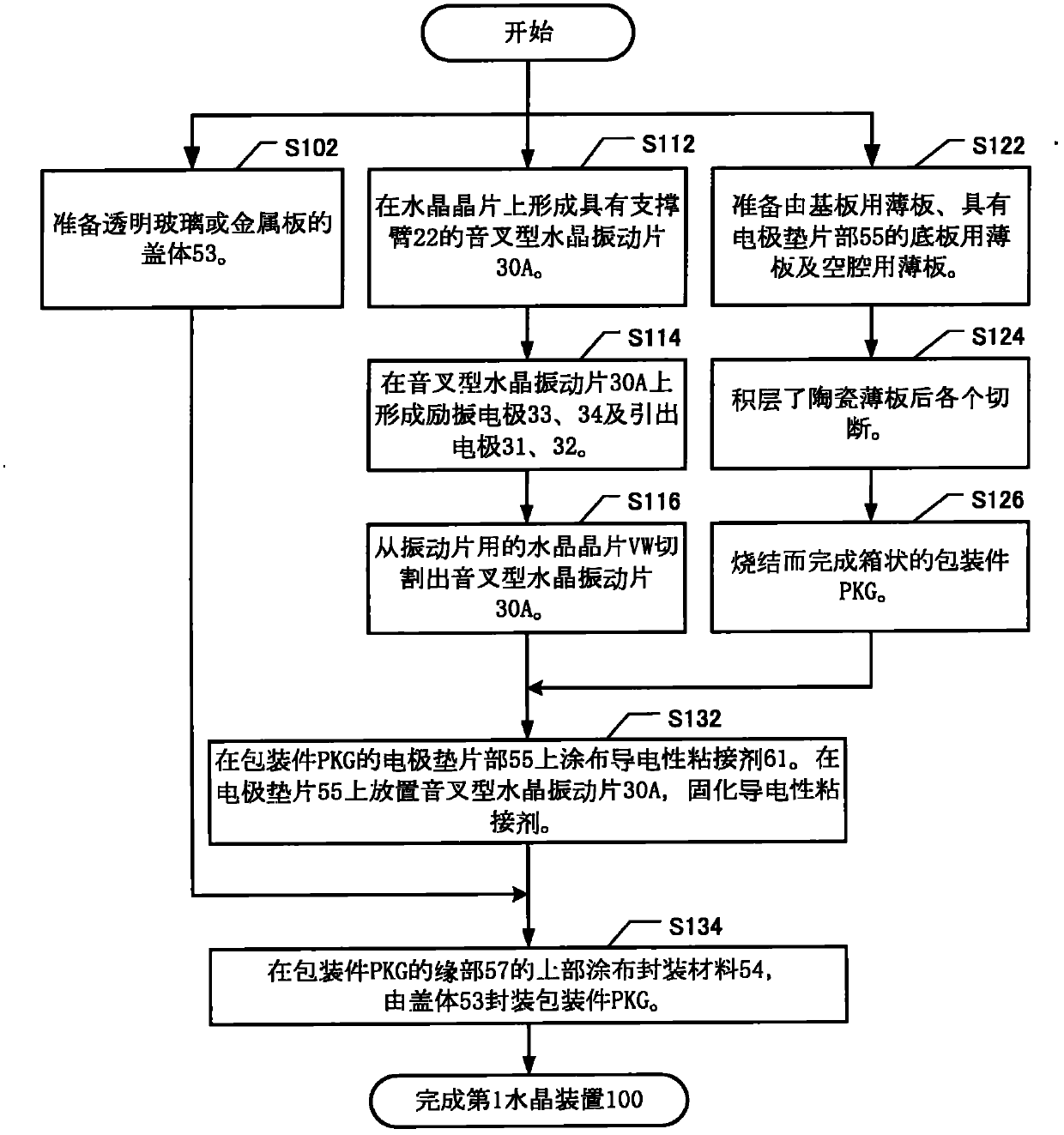

[0029] figure 1 (a) is a plan view of the first tuning-fork type crystal vibrating piece 30A, figure 1 (b) is figure 1 (a) A-A' sectional view of the first tuning-fork type crystal vibrating piece 30A. The first tuning-fork-type crystal vibrating piece 30A has a pair of tuning-fork-shaped vibrating arms 21 and support arms 25 at the base 23 .

[0030] Such as figure 1 As shown in (a), the base portion 23 of the first tuning-fork type crystal vibrating piece 30A is genera...

no. 2 Embodiment approach

[0081]

[0082] Figure 6 (a) is a perspective view showing the structure of the second crystal device 110 of the present invention, Figure 6 (b) is in Figure 6 The C-C' section in (a) is a schematic cross-sectional view showing a state where the second crystal device 110 is separated. Figure 6 (a) is the figure which looked at the surface mount (SMD) type 2nd crystal device 110 from the cover 10 side.

[0083] Such as Figure 6 The second crystal device 110 shown in (a) consists of a crystal wafer made of a cover 10, a crystal lens made of a crystal frame 20 including a second tuning-fork type crystal vibrating piece 30B, and a crystal wafer made of a substrate 40. 3 layers to form the package 80 .

[0084] The substrate 40 has a first external electrode 45 and a second external electrode 46 on the bottom surface. The substrate 40 has a substrate-side concave portion 47 on one surface on the side of the crystal frame 20 . The substrate 40 has a through hole TH and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com