Polyester resin bottom powder as well as lamp coated by same and coating method thereof

A polyester resin and base powder technology, applied in polyester coatings, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as poor resistance to chloride ion penetration, poor UV resistance, and complicated procedures, and achieve Good chemical corrosion resistance and UV resistance, good chemical corrosion resistance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

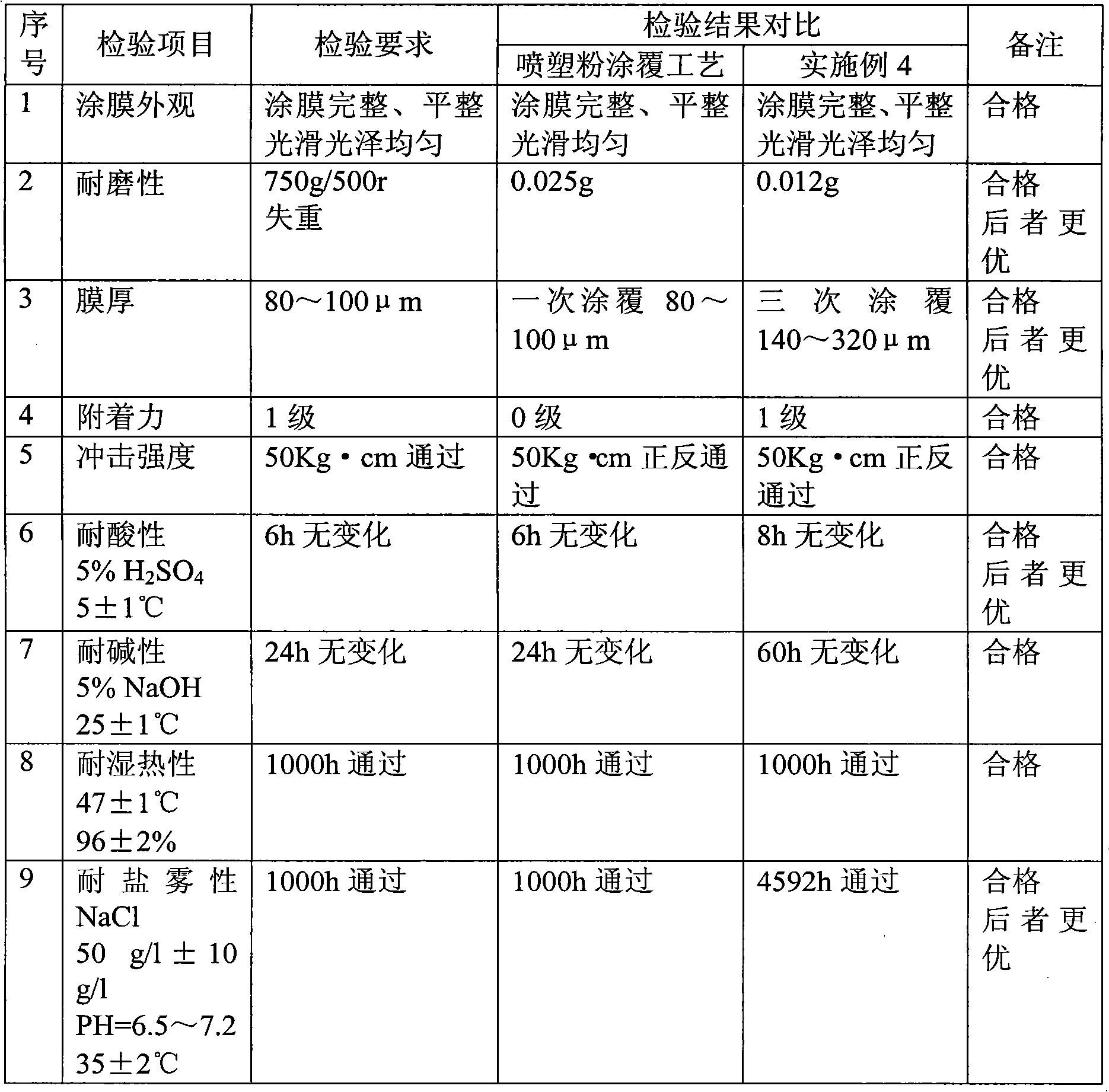

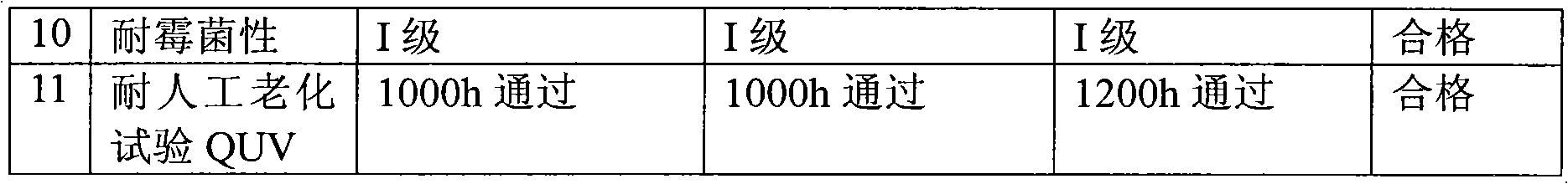

Examples

Embodiment 1

[0045] A polyester resin base powder, comprising 58.5% (percentage by weight, the same below) of fluorocarbon carboxyl saturated polyester resin, 5% epoxy acrylic resin, 5% triglycidyl isocyanurate, 2.0% Additives, 12.0% titanium dioxide, 3.0% carbon powder and 14.5% filler.

Embodiment 2

[0047] A polyester resin base powder, including 54% fluorocarbon carboxyl saturated polyester resin, 6% epoxy acrylic resin, 6% triglycidyl isocyanurate, 1.8% additives, 13.2% titanium dioxide , 3.3% toner and 15.7% filler.

Embodiment 3

[0049] A polyester resin base powder, including 62.8% fluorocarbon carboxyl saturated polyester resin, 4% epoxy acrylic resin, 4% triglycidyl isocyanurate, 2.2% additives, 10.8% titanium dioxide , 2.7% toner and 13.5% filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com