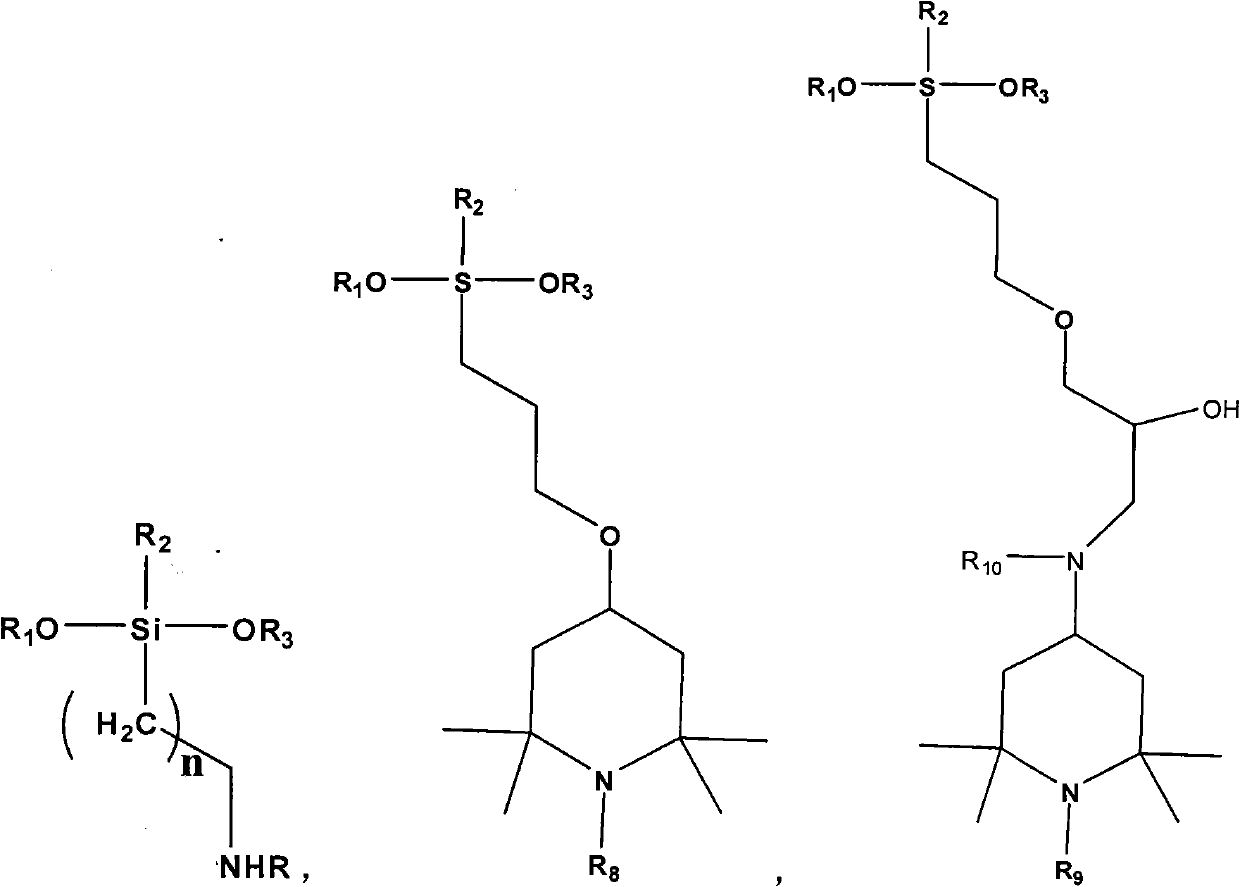

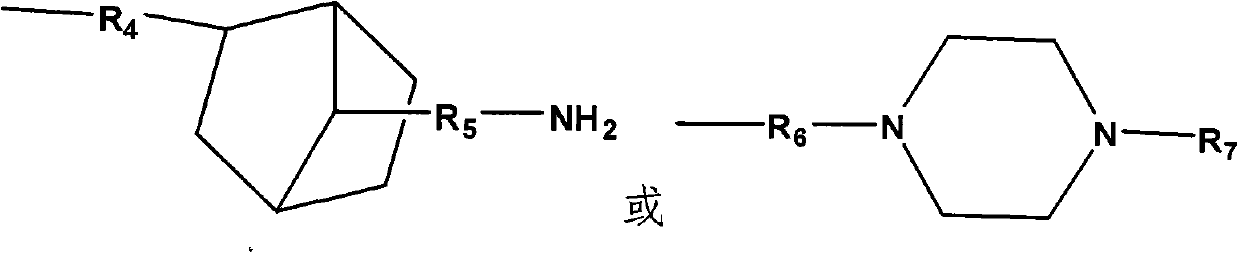

Amino modified silicone oil and preparation method thereof

A technology of amino-modified silicone oil and dihydroxy silicone oil, applied in the direction of carbon fiber, etc., can solve the problems of uneven distribution of groups, easy formation of floating oil on the surface, wide molecular weight distribution of amino-modified silicone oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 30g of dihydroxy silicone oil, 2g of aminosilane coupling agent 602 and 50mg of alkali gel of tetramethylammonium hydroxide to a 100mL three-necked bottle, blow argon gas, and vacuum at low vacuum for 30min. Raise the temperature to 85°C, equilibrate the reaction for 1h under the protection of argon, then slowly start vacuuming, start to control it below -0.02MPa, slowly increase the vacuum degree to -0.09MPa, and vacuumize for 30min; then raise the temperature to 95°C, and stir the reaction 30min; add 0.01mL of n-hexanol, continue to react for 30min; use the same method to vacuumize at -0.09MPa for 1h; release the vacuum, raise the temperature to 165°C under the protection of argon, stir for 1h, destroy the catalyst, and raise the temperature to 200°C to remove the vacuum For small molecules, cool to room temperature. The obtained amino-modified silicone oil had a viscosity of 3750 cSt, and the metal ion content in the product was determined to be 0.021 ppm by ICP....

Embodiment 2

[0036] Add 30g of dihydroxy silicone oil, 2g of aminosilane coupling agent 602 and 36mg of alkali gel of tetramethylammonium hydroxide to a 100mL three-necked bottle, blow argon gas, and evacuate at a low vacuum for 30min. Raise the temperature to 70°C, equilibrate the reaction for 1h under the protection of argon, then slowly start vacuuming, start to control it below -0.02MPa, slowly increase the vacuum degree to -0.09MPa, and vacuumize for 30min; then raise the temperature to 95°C, and stir the reaction 30min; add 0.008mL of octadecylamine, and continue to react for 30min; use the same method to vacuumize at -0.09MPa for 1h; release the vacuum, raise the temperature to 165°C under the protection of argon, stir for 1h, destroy the catalyst, and heat up to 180°C to remove the vacuum. Remove small molecules and cool to room temperature. The obtained amino-modified silicone oil had a viscosity of 2000cSt, and the metal ion content in the product was determined to be 0.022ppm by...

Embodiment 3

[0038] Add 30g of dihydroxysilicone oil and 2g of aminomethyl [N-(3-dimethoxymethylsilyl) propylaminomethyl] propane and alkali glue 100mg of tetramethylammonium hydroxide to a 100mL three-necked bottle , argon blowing, low vacuum vacuum 30min. Raise the temperature to 95°C, equilibrate the reaction for 1 hour under the protection of argon, then slowly start vacuuming, start to control it below -0.02MPa, slowly increase the vacuum degree to -0.09MPa, and vacuumize for 30min; then raise the temperature to 105°C, and stir the reaction 30min; add 0.005mL of hexamethyldisiloxane, and continue to react for 30min; use the same method to vacuumize at -0.09MPa for 1h; release the vacuum, raise the temperature to 165°C under the protection of argon, stir for 1h, destroy the catalyst, and raise the temperature to 200 ℃ to vacuum to remove small molecules, and cooled to room temperature. The obtained amino-modified silicone oil had a viscosity of 8140 cSt, and the metal ion content in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com