High-silica blue luminescent glass and preparation method thereof

A technology of luminescent glass and high-silica, which is applied in the field of preparation of high-silica blue luminescent glass and high-silica blue luminescent glass, which can solve the problem of low doping concentration of rare earth ions, limiting the application of quartz glass, and unfavorable device size to improve luminous efficiency, avoid concentration quenching effect, and facilitate absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

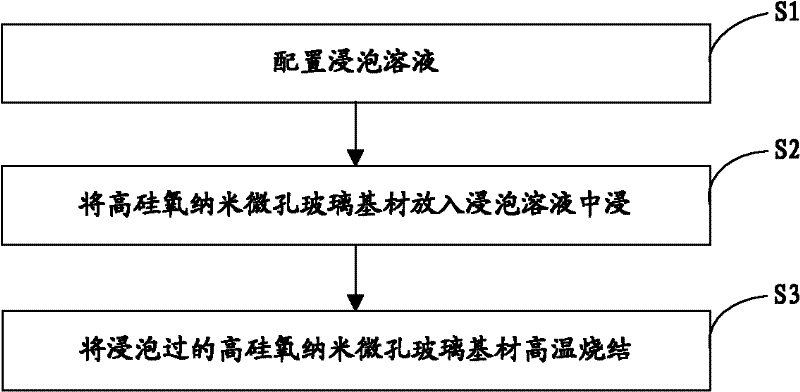

Method used

Image

Examples

Embodiment 1

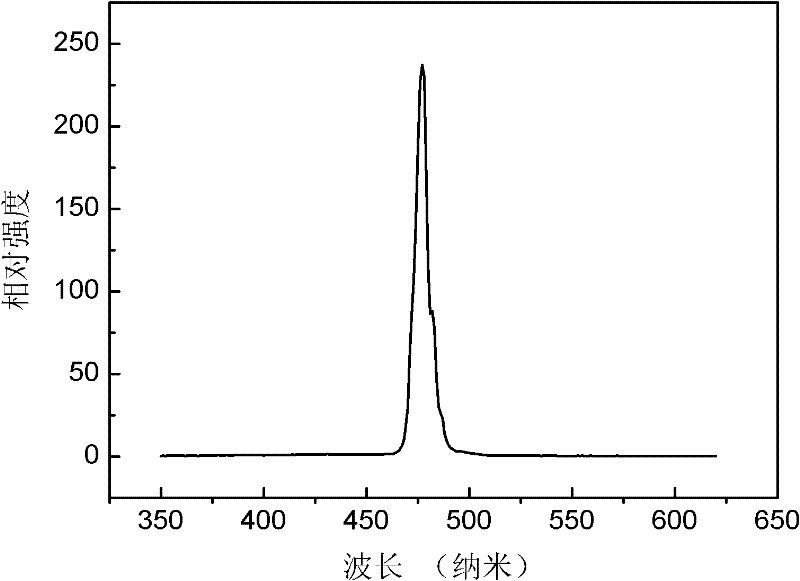

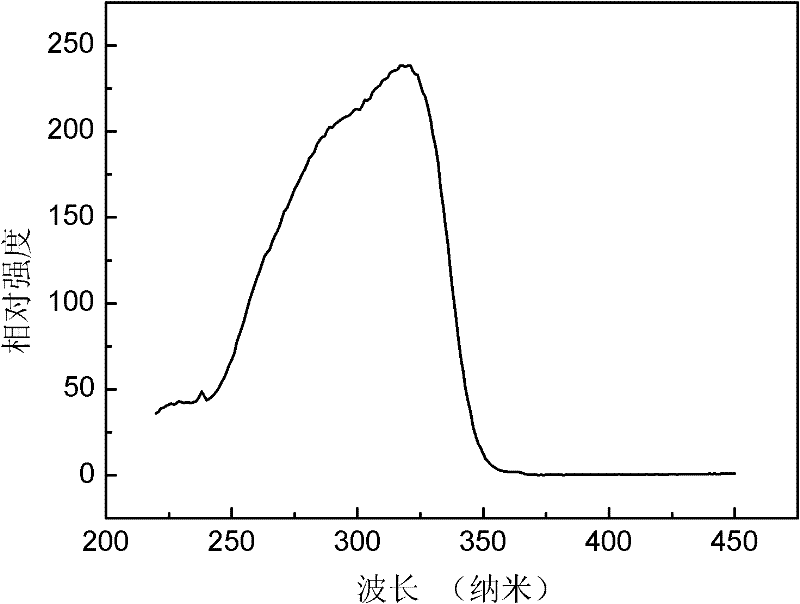

[0031] Weigh 0.099mol of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O), 0.1mol vanadyl sulfate (VOSO 4 ) and 0.001mol of thulium nitrate hexahydrate (Tm(NO 3 ) 3 )·6H 2 O was dissolved in 100ml of distilled water and prepared to contain 0.99mol / L Y 3+ , 1mol / L vanadium ion and 0.01mol / L Tm 3+ soaking solution. High silica nanoporous glass (94.0% SiO 2 , 3.0% B 2 o 3 , 3.0% Al 2 o 3and the microporous volume accounts for 25% of the total volume of the high-silica nano-microporous glass) soaked in the soaking solution for 10 minutes and then taken out, aired at room temperature until the surface is dry and put into the high-temperature furnace, the heating process of the high-temperature furnace is: first Raise to 400°C at a speed of 10°C / min, then to 900°C at a speed of 15°C / min, and then to 1300°C at a speed of 5°C / min, heat-preserve and sinter the soaked microporous glass at 1300°C for 2 hours, The glass is cooled to room temperature with the furnace and taken...

Embodiment 2

[0033] Weigh 0.1mol of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O), weigh 0.09mol of gadolinium nitrate hexahydrate (Gd(NO 3 ) 3 ·6H 2 O), 0.2mol vanadyl sulfate (VOSO 4 ) and 0.01mol of thulium nitrate hexahydrate (Tm(NO 3 ) 3 )·6H 2 O was dissolved in 100ml of distilled water and prepared to contain 1mol / L Y 3+ , 0.9mol / L Gd 3+ , 2mol / L vanadium ions and 0.1mol / L Tm 3+ soaking solution. High silica nanoporous glass (96.0% SiO 2 , 3.0% B 2 o 3 , 1.0% Al 2 o 3 and the volume of micropores accounts for 30% of the total volume of the high-silica nano-microporous glass) soaked in the soaking solution for 4h and then taken out, aired at room temperature until the surface is dry and then placed in a high-temperature furnace, the heating process of the high-temperature furnace is: first Rise to 400°C at a speed of 10°C / min, then to 900°C at a speed of 15°C / min, and then to 1150°C at a speed of 5°C / min, heat-preserve and sinter the soaked microporous glass at 115...

Embodiment 3

[0035] Weigh 0.09999mol of lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 O), 0.1mol of ammonium metavanadate (NH 4 VO 3 ) and 10 -5 mol of thulium nitrate hexahydrate (Tm(NO 3 ) 3 )·6H 2 O was dissolved in 1000ml of distilled water and prepared to contain 0.09999mol / L La 3+ , 0.1mol / L vanadium ions and 10 -5 mol / L Tm 3+ soaking solution. High silica nanoporous glass (98.0% SiO 2 , 1.0% B 2 o 3 , 1.0% Al 2 o 3 and the micropore volume accounts for 35% of the total volume of the high-silica nano-microporous glass) soaked in the soaking solution for 30min and then taken out, aired at room temperature until the surface is dry and put into the high-temperature furnace, the heating process of the high-temperature furnace is: first Rise to 400°C at a speed of 10°C / min, then to 900°C at a speed of 15°C / min, and then to 1200°C at a speed of 5°C / min, heat-preserve and sinter the soaked microporous glass at 1200°C for 4 hours, The glass is cooled to room temperature wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com