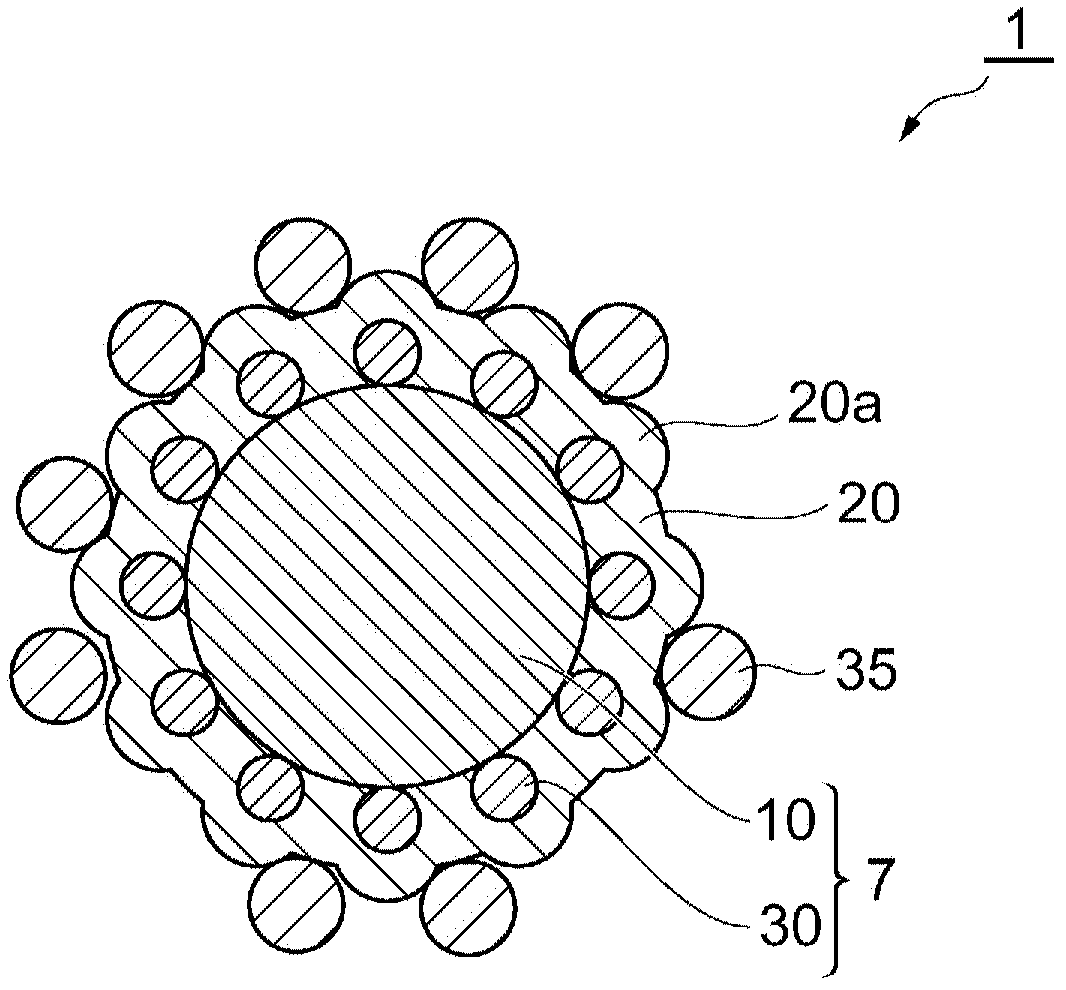

Conductive particle

A conductive particle and non-conductive technology, applied in the field of conductive particles, can solve problems such as short circuit and difficulty in ensuring conductivity, and achieve the effects of preventing poor conduction, sufficient conductivity, and preventing insufficient insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

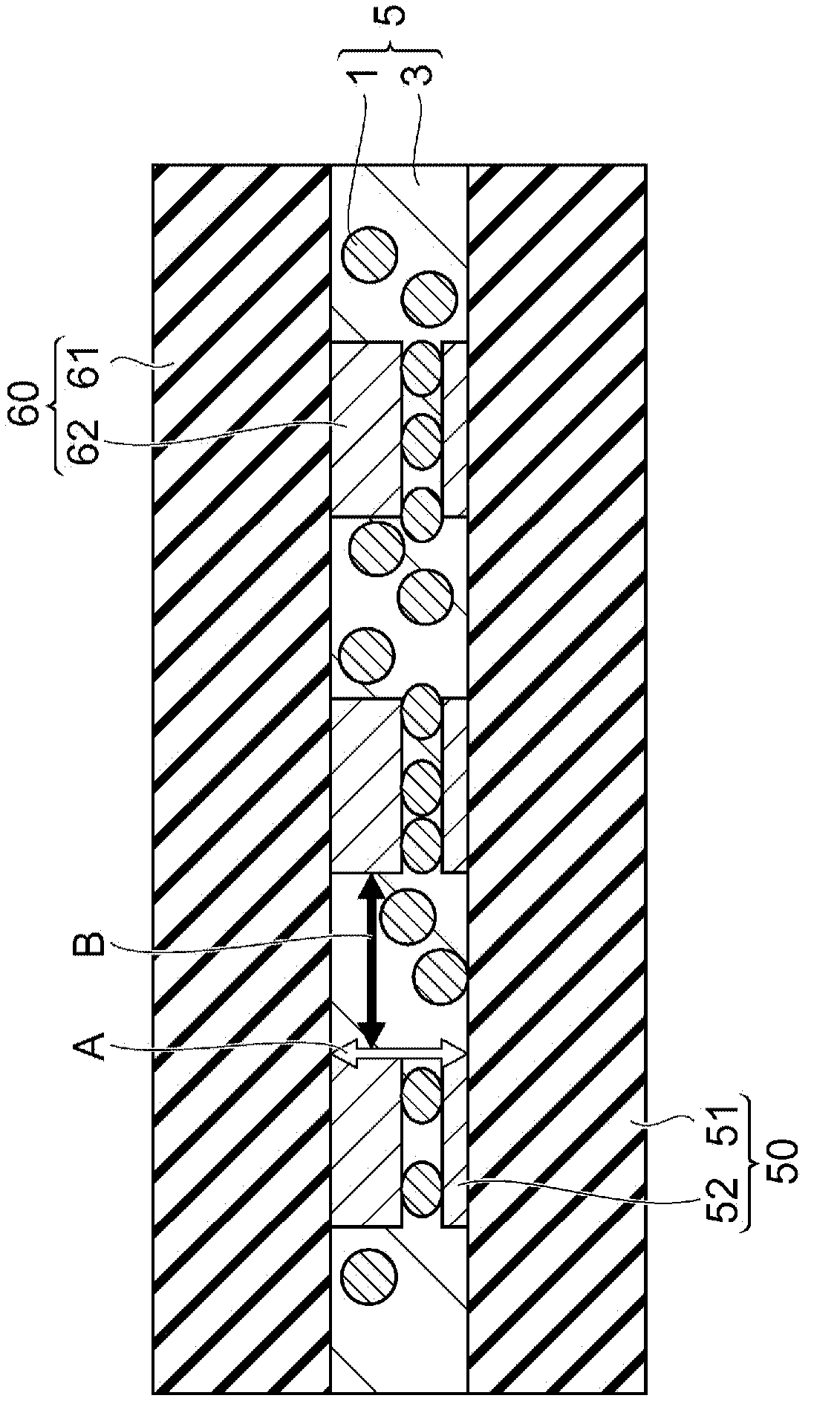

Method used

Image

Examples

Embodiment 1

[0115] (1) Preparation of conductive particles

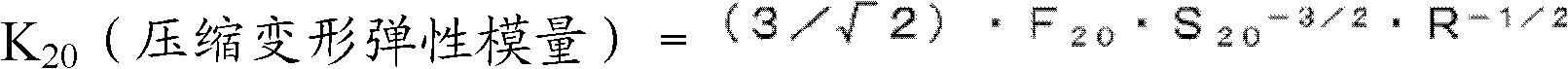

[0116] 10 g of plastic nuclei comprising a copolymer of divinylbenzene and acrylic acid and having an average particle diameter of 3.7 μm with an adjusted degree of crosslinking were prepared. The surface of the plastic core has carboxyl groups. The hardness of the plastic core (compression elastic modulus when the particle diameter is deformed by 20% at 200°C, 20% K value) is 150kgf / mm 2 .

[0117] A 30% by mass polyethyleneimine aqueous solution (manufactured by Wako Pure Chemical Industries, Ltd.) having a molecular weight of 70,000 was diluted to 0.3% by mass with ultrapure water. 10 g of the above-mentioned plastic core was added to 300 mL of this 0.3 mass % polyethylene aqueous solution, and stirred at room temperature for 15 minutes. The plastic nucleus was taken out by filtration using a φ3 μm membrane filter (Millipore, Inc.), and the taken plastic nucleus was added to 300 g of ultrapure water and stirred at room tem...

Embodiment 2

[0129] In the same manner as in Example 1, except that 0.53% by mass of silica particle dispersion (total amount of silica: 1.6 g) was used instead of 0.33% by mass of silica particle dispersion (total amount of silica: 1 g). , Plastic cores (composite particles) with silica particles adsorbed on their surfaces, and conductive particles 2 with nickel films formed on their surfaces were prepared. Furthermore, the anisotropic conductive adhesive film and bonded structure samples were produced by the procedure similar to Example 1 using the obtained electroconductive particle 2.

Embodiment 3

[0131] In the same manner as in Example 1, except that 0.42% by mass of silica particle dispersion (total amount of silica: 1.27 g) was used instead of 0.33% by mass of silica particle dispersion (total amount of silica: 1 g). , and the plastic core (composite particle) on which the silica particles were adsorbed on the surface, and the conductive particle 3 on which the nickel film was formed were produced. Furthermore, the anisotropic conductive adhesive film and bonded structure samples were produced by the procedure similar to Example 1 using the obtained electroconductive particle 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com