Method for determination of brittle crack propagation stopping performance in high-intensity thick steel plate

A technology of brittle crack propagation and judgment method, which is applied in the direction of strength characteristics, testing material strength with one-time impact force, instruments, etc., can solve a lot of procedures and time problems, and achieve the effect of simple method, effective quality management, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0076] Hereinafter, a method of judging the brittle crack propagation stopping performance of the high-strength thick steel plate according to the first embodiment of the present invention will be described with reference to the drawings.

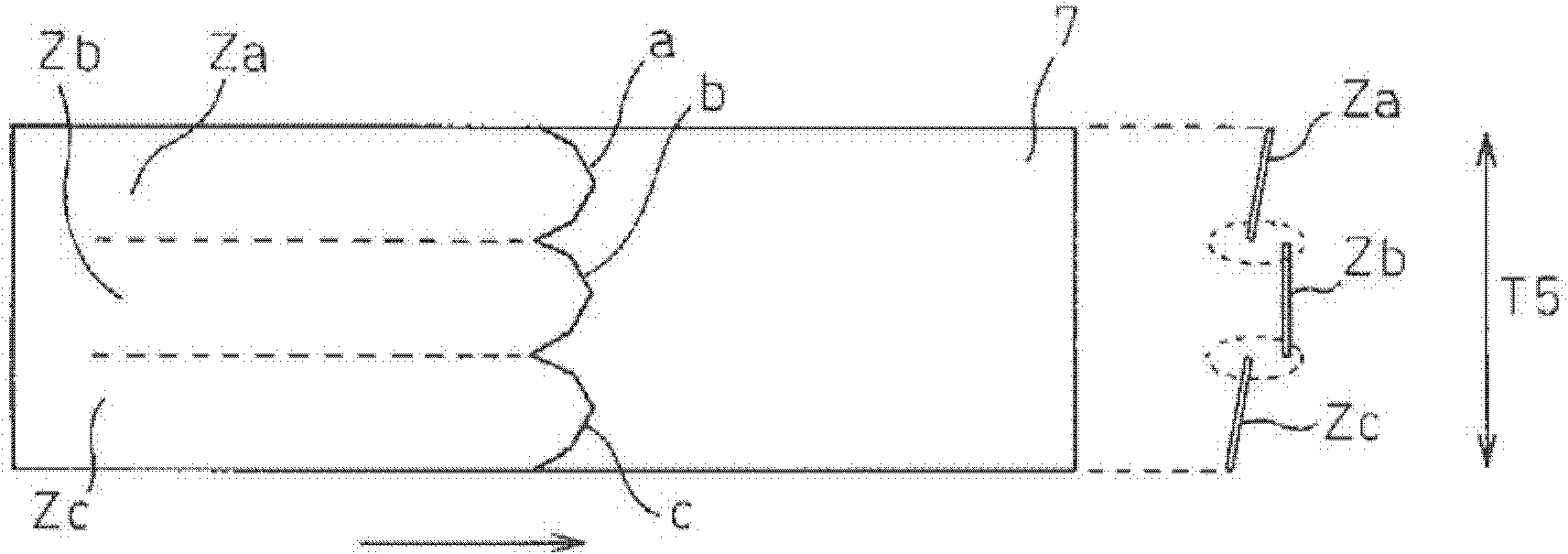

[0077] The high-strength thick steel plate to be targeted by the determination method of this embodiment is a steel plate for large ship hulls or iron water supply pipes, preferably with a plate thickness of 50 mm or more and a yield strength of 240 to 1000 N / mm 2 . First, for example, 5 to 10 high-strength thick steel plates as standard steel are produced with a specific composition and production method, and the Kca value of the high-strength thick steel plate is obtained by the ESSO test using the method disclosed in Non-Patent Documents 1 and 2. In addition, small test pieces were taken from thick steel plates of the above-mentioned standard steel, and the characteristic values of the small test pieces were obtained by performing vari...

no. 2 Embodiment approach

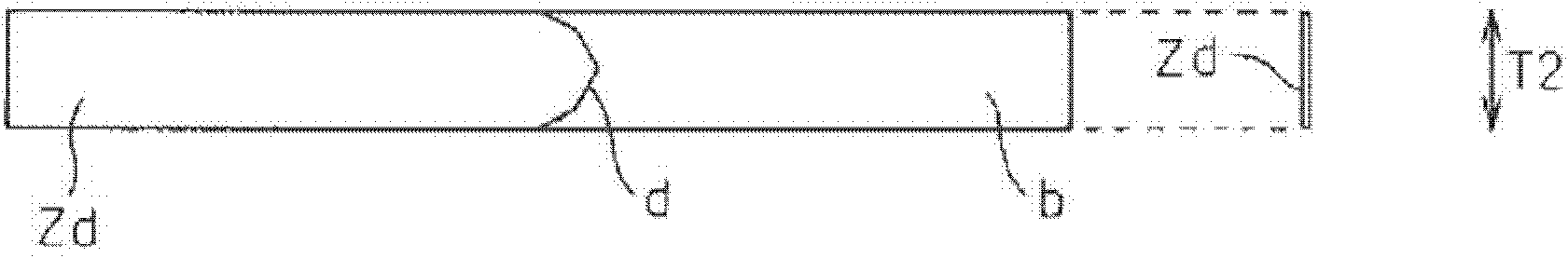

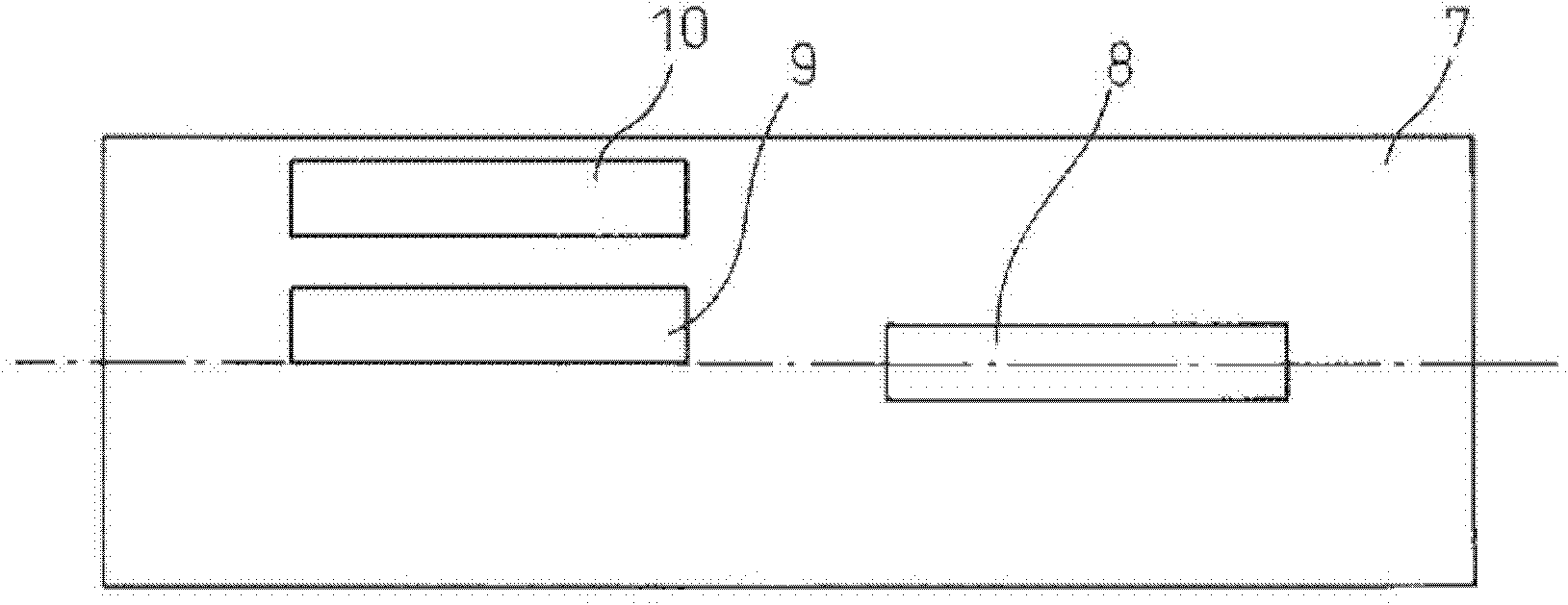

[0141] Hereinafter, a method of judging the brittle crack propagation stopping performance of the high-strength thick steel plate according to the second embodiment of the present invention will be described. The difference between the above-mentioned first embodiment and this embodiment is that internal small-scale test pieces for the internal small-scale test are collected from two regions inside the steel plate in order to judge the brittle crack propagation stopping performance with higher accuracy. In the method of this second embodiment, the surface layer small test piece is obtained from Figure 2B Position 12 shown is taken. Internal small test piece from Figure 2B Both sides of the two sites shown in 9a and 11 are taken. As a small surface layer test, a drop weight impact test was performed in the same manner as in the first embodiment. The V-notch Charpy impact test or the Herringbone-notch Charpy impact test is performed using the internal small-scale test of tw...

Embodiment 1

[0157]The composition of steel plates used in this example is shown in Table 1. The main rolling conditions, cooling conditions, heat treatment conditions, plate thickness and yield strength YS of each steel plate are shown in Table 2. From these thick steel plates with a plate thickness of 70 mm Figure 2B In the shown collection form, a small test piece was taken. Table 3 described later shows the types of small-scale tests performed on the steel samples and the locations where the small-scale test pieces were collected.

[0158] Table 1

[0159]

[0160] Table 2

[0161]

[0162] The results of the V-notch Charpy impact test are represented by a temperature representing a 50% brittle fracture rate called a fracture shape transition temperature: vTrs. The results of the chevron notch Charpy impact test are shown by the transition temperature at which absorbed energy of 70J can be ensured. The results of the sharp notch Charpy impact test are shown by the transitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com