Magnetic refrigeration working medium bed and preparation method

A technology of magnetic refrigeration and working medium bed, which is applied in the fields of magnetic refrigeration working medium bed and its preparation, magnetic refrigeration working medium bed and its preparation, and can solve the problems of large longitudinal heat leakage, decreased heat transfer specific surface area of magnetic refrigeration working medium bed, and poor It is possible to realize cooling temperature span and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

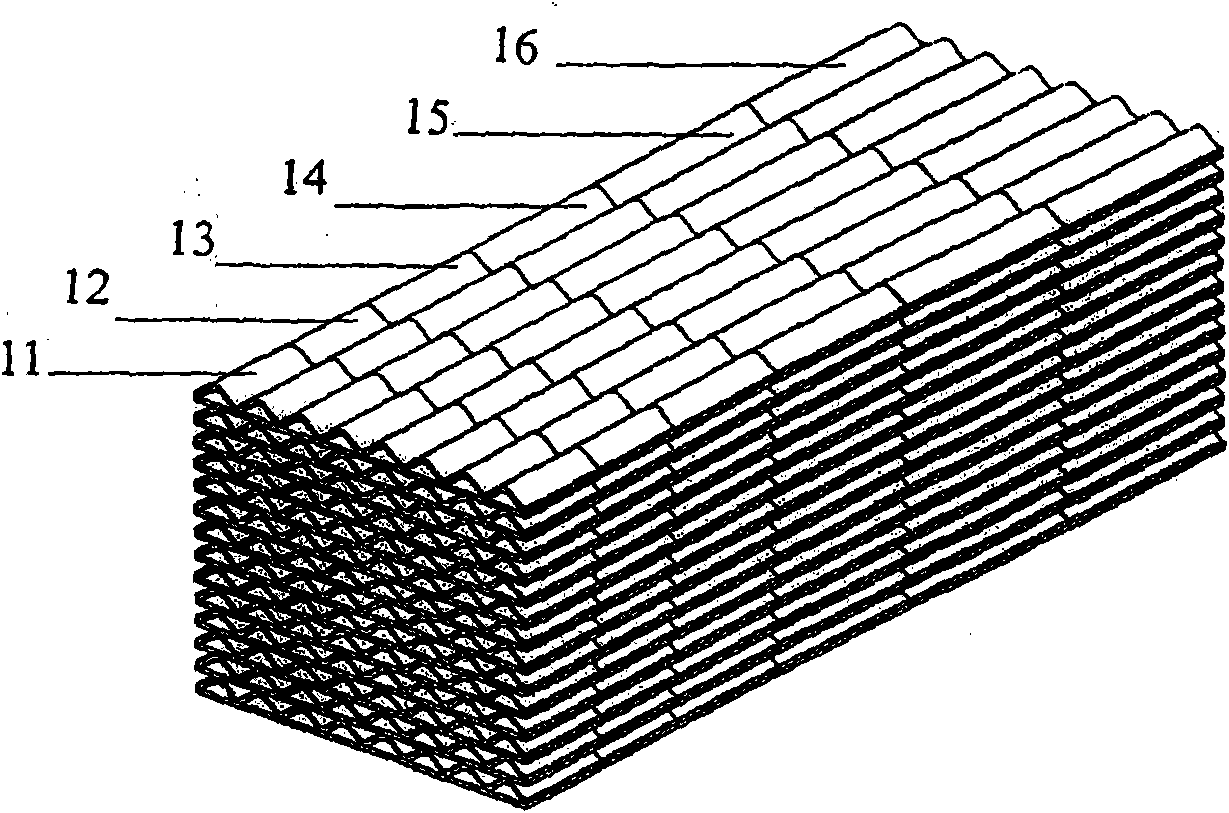

[0037] Example 1: The preparation of the present invention is used to realize the active magnetic regenerating magnetic refrigeration working medium bed with an ambient temperature of 30°C and a refrigeration temperature of 25°C.

[0038] 1) Preparation of magnetic refrigeration powder materials:

[0039] Preparation of La(FeSi) with a Curie point temperature of 27.5°C 13 h 1.5 Magnetic refrigeration powder materials;

[0040] 2) Preparation of sheet magnetic refrigerant bed components:

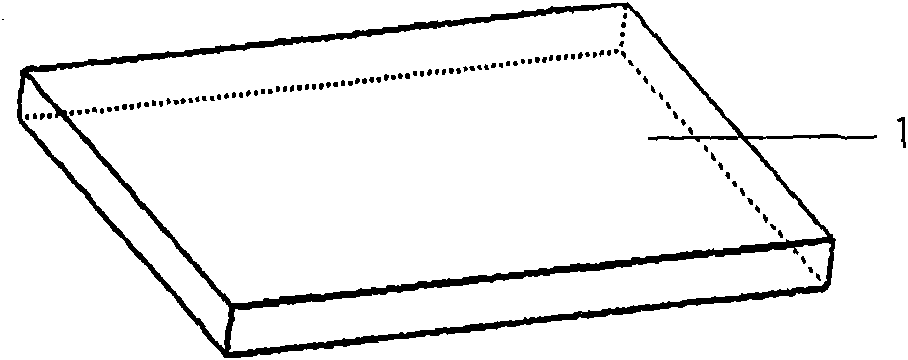

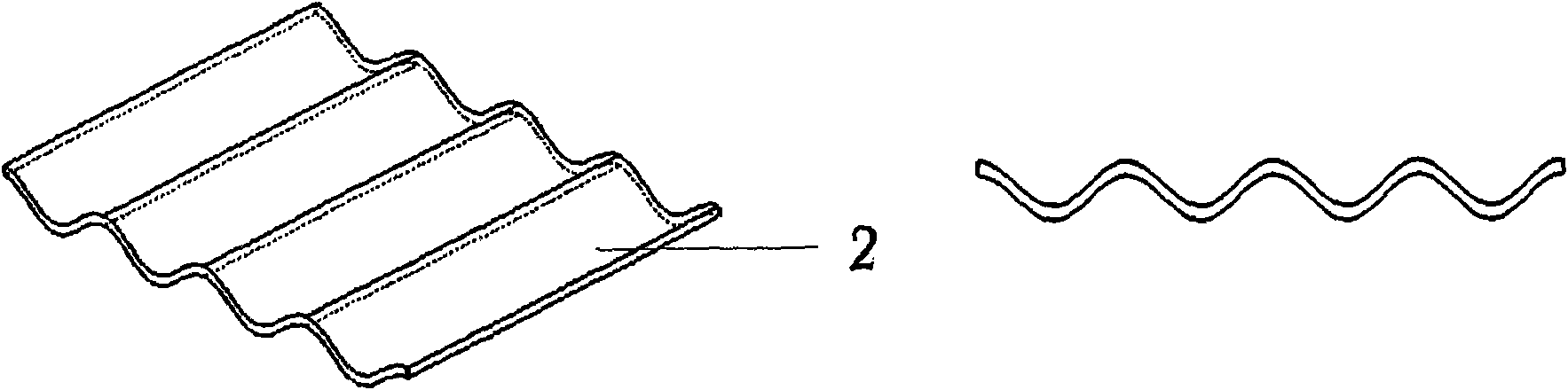

[0041] La(FeSi) 13 h 1.5 The magnetic refrigeration powder material is evenly immersed in the phenolic bonding colloid to obtain the La(FeSi)-containing 13 h 1.5 A mixture of magnetic refrigeration powder material and phenolic bonding colloid, the content of the phenolic bonding colloid accounts for 10%wt of the mixture weight; then the mixture is packed into a mold and compacted into a flat surface with a thickness of 0.5mm Straight flakes 1 (such as Figure 2a shown) and flat waves ...

Embodiment 2

[0043] Example 2: The preparation of the present invention is used to realize the active magnetic regenerating magnetic refrigeration working medium bed with an ambient temperature of 30°C and a refrigeration temperature of 5°C.

[0044] 1) Preparation of magnetic refrigeration powder materials:

[0045] Designed according to the requirements of the magnetic refrigerator and changing the content of the gap H by adjusting the hydrogen absorption process to prepare 10 kinds of magnetic refrigeration powder materials with a Curie point temperature from 7.5°C to 30°C (the interval is 2.5°C): La(FeSi) 13 h 1.05 , La(FeSi) 13 h 1.1 , La(FeSi) 13 h 1.15 , La(FeSi) 13 h 1.2 , La(FeSi) 13 h 1.25 , La(FeSi) 13 h 1.3 , La(FeSi) 13 h 1.35 , La(FeSi) 13 h 1.4 , La(FeSi) 13 h 1.45 and La(FeSi) 13 h 1.5 ;

[0046] 2) Preparation of sheet magnetic refrigerant bed components:

[0047] Each magnetic refrigeration powder material was evenly immersed in the epoxy resin bonding...

Embodiment 3

[0050] Embodiment 3: The present invention is used to realize an active magnetic regenerating magnetic refrigeration working medium bed with an ambient temperature of 30°C and a refrigeration temperature of 25°C.

[0051] 1) Preparation of magnetic refrigeration powder materials:

[0052] Design according to the requirements of the magnetic refrigerator and change the content of gap C and H by adjusting the hydrogen absorption process to prepare La(FeSi) with a Curie point temperature of 27.5°C 13 C 0.2 h 1.5 Magnetic refrigeration powder materials;

[0053] 2) Preparation of sheet magnetic refrigerant bed components:

[0054] La(FeSi) 13 C 0.2 h 1.5 The magnetic refrigeration powder material is uniformly immersed in the phenolic bonding colloid to obtain La(FeSi) 13 C 0.2 h 1.5 A mixture of magnetic refrigeration powder material and phenolic bonding colloid; the content of the phenolic bonding colloid accounts for 5% of the weight of the mixture; and then the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com