Target material and its application in recording layer material of magnetic recording media

A technology of magnetic recording and recording layer, applied in the direction of magnetic recording, coating with magnetic layer, data recording, etc., can solve the problems of oxide running in, the film can not meet the quality requirements, can not be provided, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the technical features and practical effects of the present invention in detail, and to implement them according to the contents of the specification, the detailed descriptions are as follows:

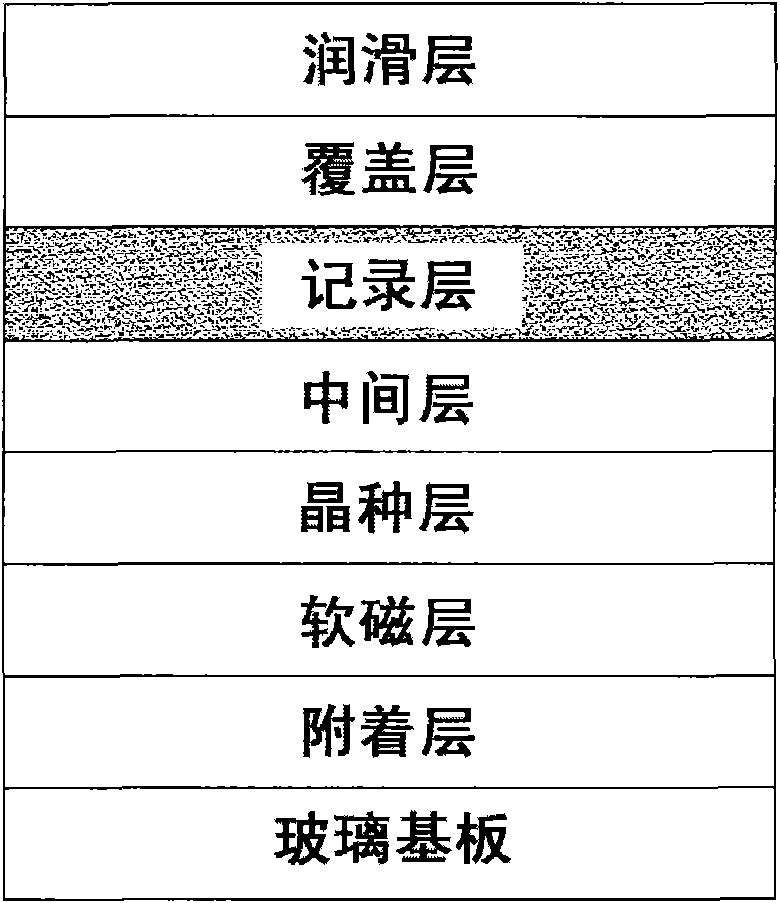

[0024] Preferred embodiments of the target material provided by the present invention and its recording layer material used in magnetic recording media are as follows Figure 4 shown.

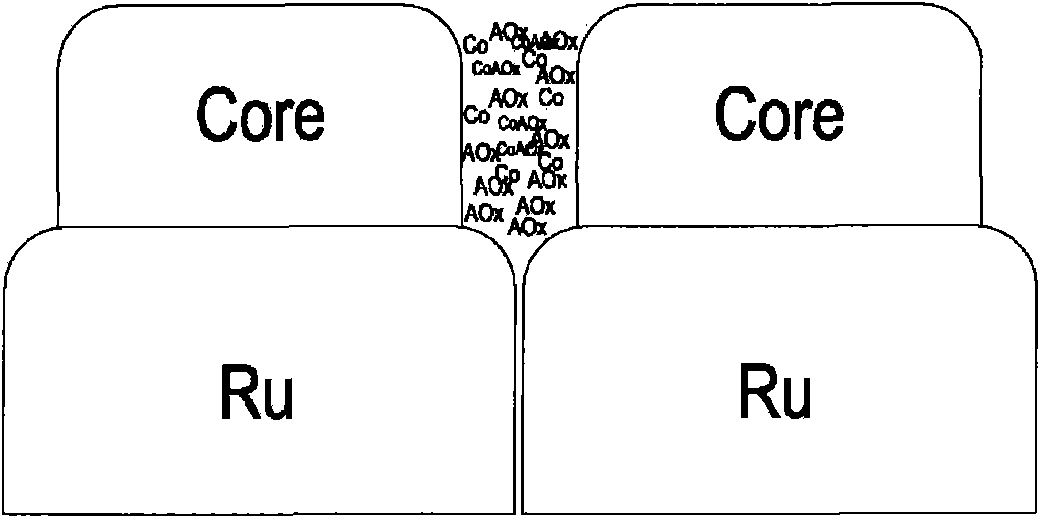

[0025] The present invention provides a recording layer material of a magnetic recording medium, which is formed by adding an oxide composition to the main material of CoPt, CoCrPt or CoCrPtB; wherein the oxide composition contains copper oxide (CuO) and at least One selected from the group consisting of: titanium oxide (TiO 2 ), chromium oxide (Cr 2 o 3 ), tantalum oxide (Ta 2 o 5 ), niobium oxide (Nb 2 o 5 ), yttrium oxide (Y 2 o 3 ), zirconia (ZrO 2 ), hafnium oxide (HfO 2 ) and combinations thereof.

[0026] In other words, the present invention provides a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com