Wire clip

A wire buckle and fastener technology, which is applied to electrical components, coupling devices, circuits, etc., can solve the problems of falling off, unable to play the plug 42, and non-conforming specifications, and achieves flexible and convenient use and operation, no complicated production procedures, and component structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

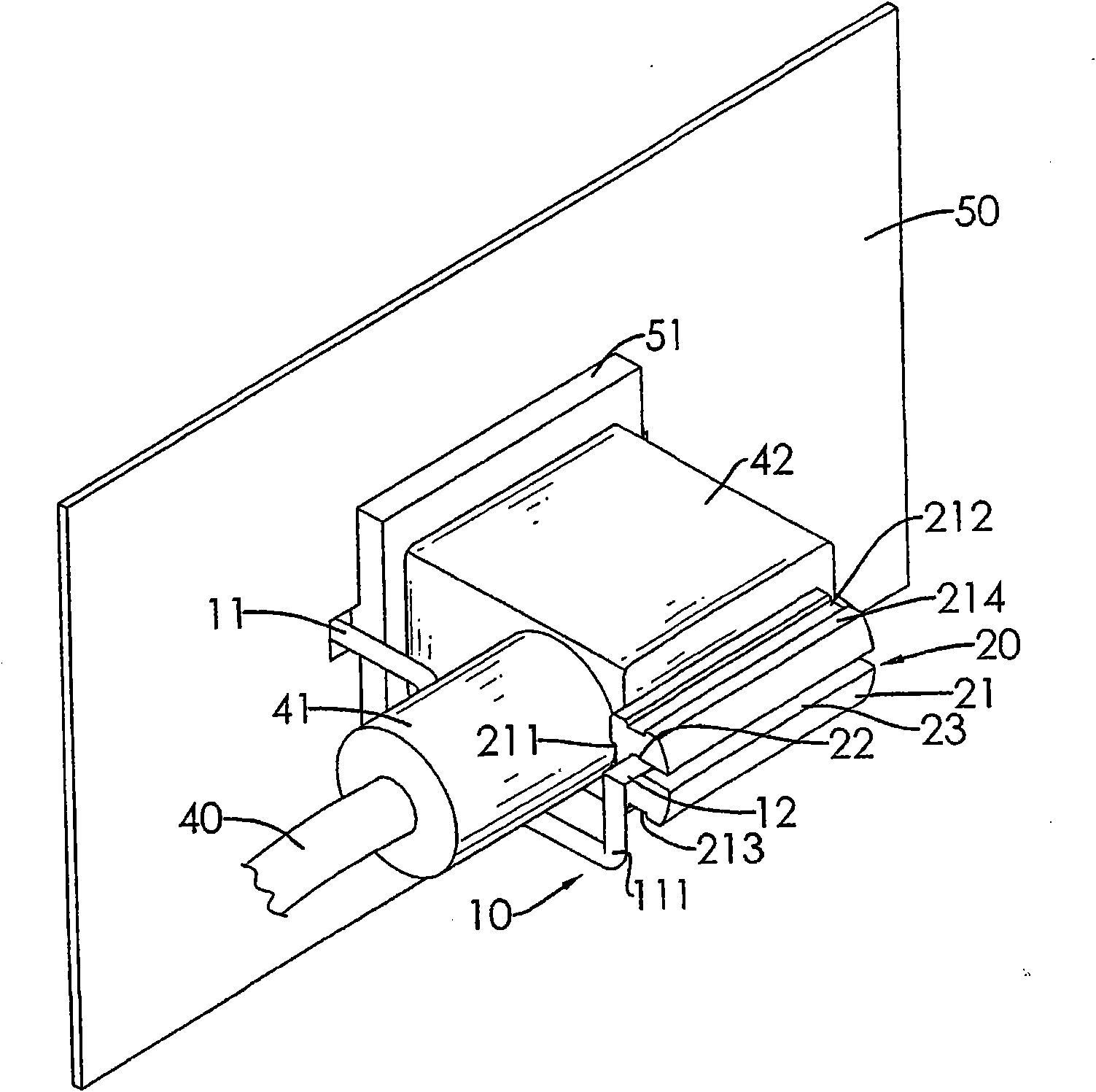

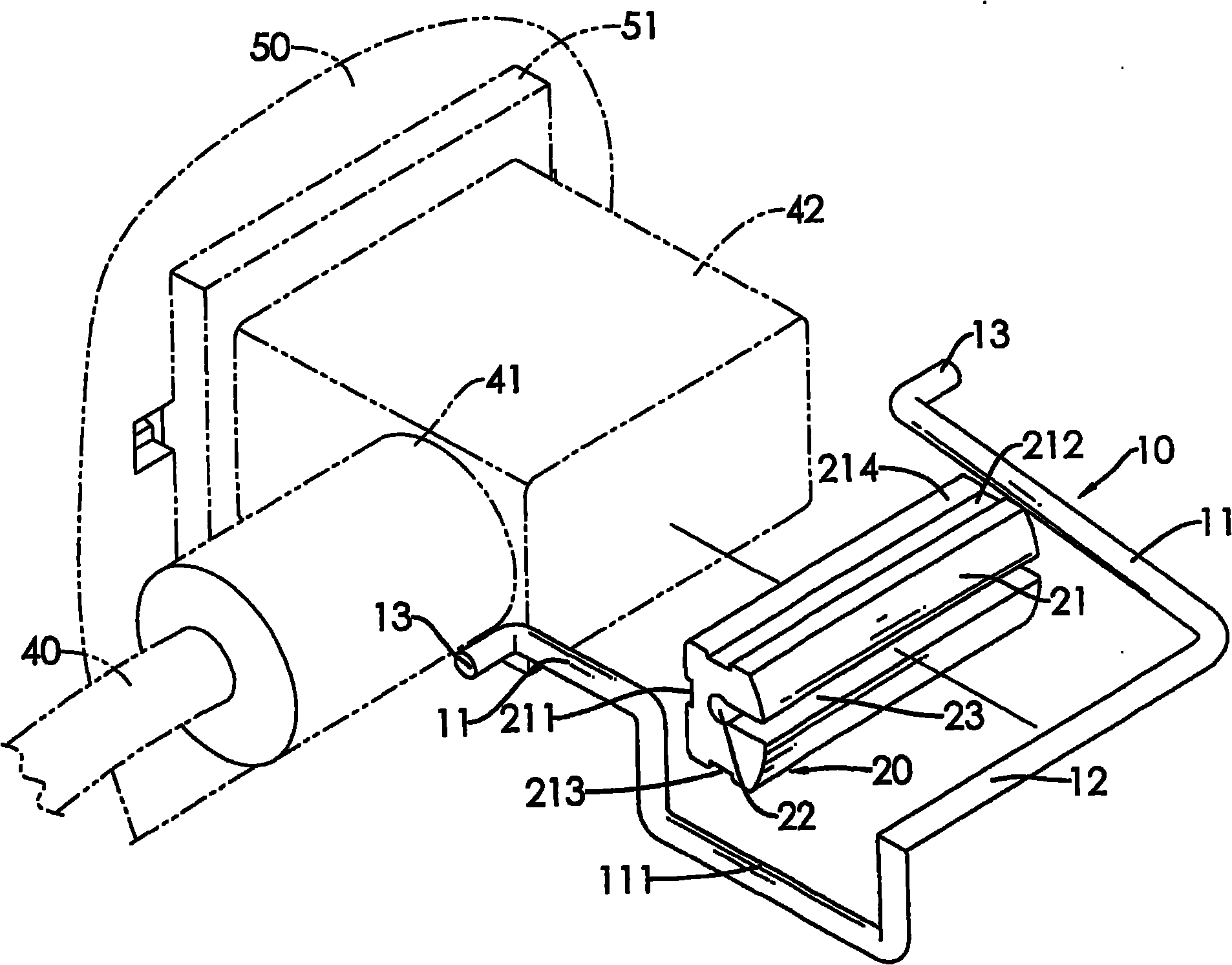

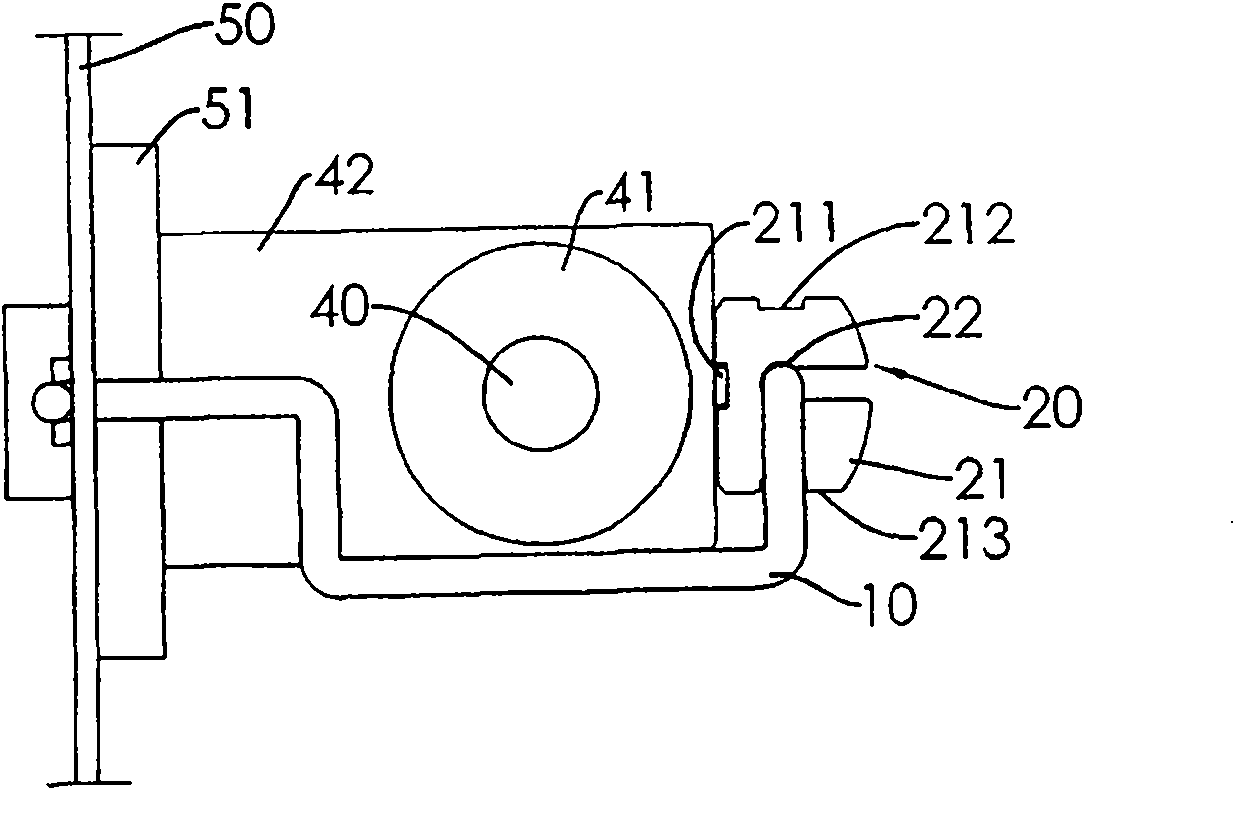

[0029] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0030] see figure 1 and figure 2 As shown, the wire buckle of the present invention includes a body 10 and a fastener 20, wherein:

[0031] The body 10 is formed by bending a rod, which can be a metal material (for example: stainless steel), and has two spaced support arms 11, and a connecting arm between one end of the two support arms 11 12, and the other end of the two support arms 11 is formed with a pivot joint 13, and the two support arms 11, the connecting arm 12 and the pivot joint 13 are located on the same plane, in addition to match the shape of the plug 42 shown in the figure, In a specific embodiment of the body 10, one support arm 11 is bent to form a concave portion 111, the concave portion 111 is designed according to the shape and position of the connecting portion 41 of the power cord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com