Modified polyimide and method for producing modified polyimide

一种聚酰亚胺、聚酰亚胺树脂的技术,应用在印刷电路制造、涂加非金属保护层、涂层等方向,能够解决耐热性降低等问题,达到密合性优异、耐化学药品性优异、可靠性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The oligomer whose terminal is isocyanate represented by the above-mentioned general formula (II) used in the preparation method of the present invention can be obtained by making the polycarbonate diol represented by the general formula (VI) and the diol represented by the general formula (VII) isocyanate reaction to obtain,

[0050] [chemical formula 8]

[0051]

[0052] (In the formula, R independently represents an alkylene group with 1 to 18 carbon atoms, and m represents an integer of 1 to 20);

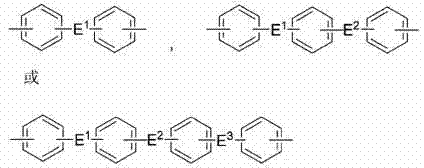

[0053] [chemical formula 9]

[0054]

[0055] (wherein, X represents an alkylene or arylene group with 1 to 18 carbon atoms or an alkylene group with 1 to 18 carbon atoms linked by an ether bond, ester bond, urethane bond or amide bond);

[0056] In the above general formula (VI), R is independently an alkylene group with 1 to 18 carbon atoms, preferably an alkylene group with 2 to 8 carbon atoms, and m is an integer of 1 to 20, preferably 6 An integer of ~16. The...

Embodiment 1~5 and comparative example 1~3

[0135] A flame-retardant modified polyimide resin composition was prepared by kneading the main ingredient and each additive component in the proportion shown in the following Table 2 with a planetary mixer manufactured by Primix Co., Ltd. Table 2 shows the results of evaluating the following items about each obtained flame-retardant modified polyimide resin composition.

[0136] Flexibility

[0137] Each flame retardant modified polyimide composition was coated on the substrate by screen printing with a stainless steel plate of 165-3D mesh (mesh), heated at 120°C for 60 minutes by a hot air oven, and then heated at 180°C. Heat up for 30 minutes. Copper foil F2-WS (18 μm) manufactured by Furukawa Corporation, Ltd. was used as the substrate. About the obtained polyimide film, the coated surface was bent 180 degrees outside, and the presence or absence of a crack in a dried film was visually judged. Judgment criteria are as follows.

[0138] ◯: The dried film has no cracks. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com