A kind of cathode material of lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor electrical conductivity and unsatisfactory high-rate charge-discharge performance, and achieve excellent performance, excellent high-rate charge-discharge performance, The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method for the above positive electrode material, comprising the following steps:

[0032] Step 1. Mix and ball mill lithium source, M source, silicon source and N source to obtain mixed powder;

[0033] Step 2, the above-mentioned mixed powder is heat-treated under an inert atmosphere to obtain a structural formula of Li 2+x MSi 1-x N x o 4 The product, wherein, M is selected from Mn, Fe or Mn 1-y Fe y , N is selected from Ti, Cr or Ti 1-z Cr z , 0.01<x≤0.5, 0<y<1, 0<z<1.

[0034] The process of the above preparation method is simple, and at the same time, the prepared material has excellent performance, stable structure, and high-rate charge-discharge performance, and the prepared positive electrode material is a nano-particle material with a uniform particle size distribution, and the average particle size distribution is between 50-100 Between nanometers, the crystal form is perfect.

[0035] In the present ...

Embodiment 1

[0046] (1) Preparation of cathode materials

[0047] 1) Weigh 92.5g of lithium carbonate, 30g of fumed silica, 57.5g of manganese carbonate, 90g of ferrous oxalate, 40g of titanium dioxide and 5g of sucrose, mix them in 500ml of ethanol, and then use a planetary ball mill at a speed of 300r / min Ball milling for 5 hours; 2) The ball-milled mixed powder was roasted and heat-treated in a box-type atmosphere furnace. Under the protection of an Ar atmosphere with a flow rate of 0.6l / min, the temperature was raised to 350°C at a heating rate of 5°C / min. Keep it warm for 10 hours, then raise the temperature to 850°C at a heating rate of 8°C / min, keep it at this temperature for 8h, and then cool it to room temperature with the furnace to obtain a carbon-coated Li 2.5 mn 0.5 Fe 0.5 Si 0.5 Ti 0.5 o 4 active material;

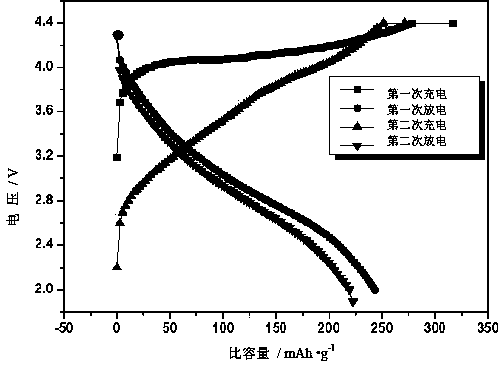

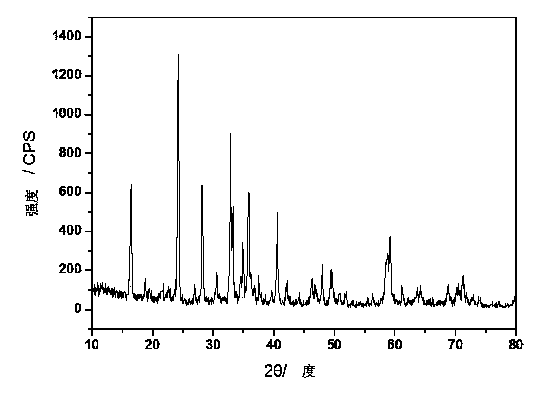

[0048] Adopt Rigaku D / MAX2200PC X-ray diffractometer (room temperature 25°C, radiation source is Cu target Kα ray, tube voltage 40kV, tube current 20 mA, scanning r...

Embodiment 2

[0053] Adopt the same method as Example 1 to prepare the positive electrode material and simulated battery, the difference is that the raw materials added are lithium oxalate 112.1g, nano silicon dioxide 48g, manganese oxalate 28.6g, ferrous chloride 101.4g, chromium trioxide 20g and Glucose 6g, to prepare Li 2.2 mn 0.2 Fe 0.8 Si 0.8 Cr 0.2 o 4 Active material, and made CR2016 button battery A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com