Scroll compressor

A technology of scroll compressors and compression chambers, which is applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., which can solve the problems of decreased suction heating performance, increased gas specific volume, and decreased energy efficiency, etc., to achieve suppression Effects of heating, high-efficiency scroll compressor, and prevention of sealing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

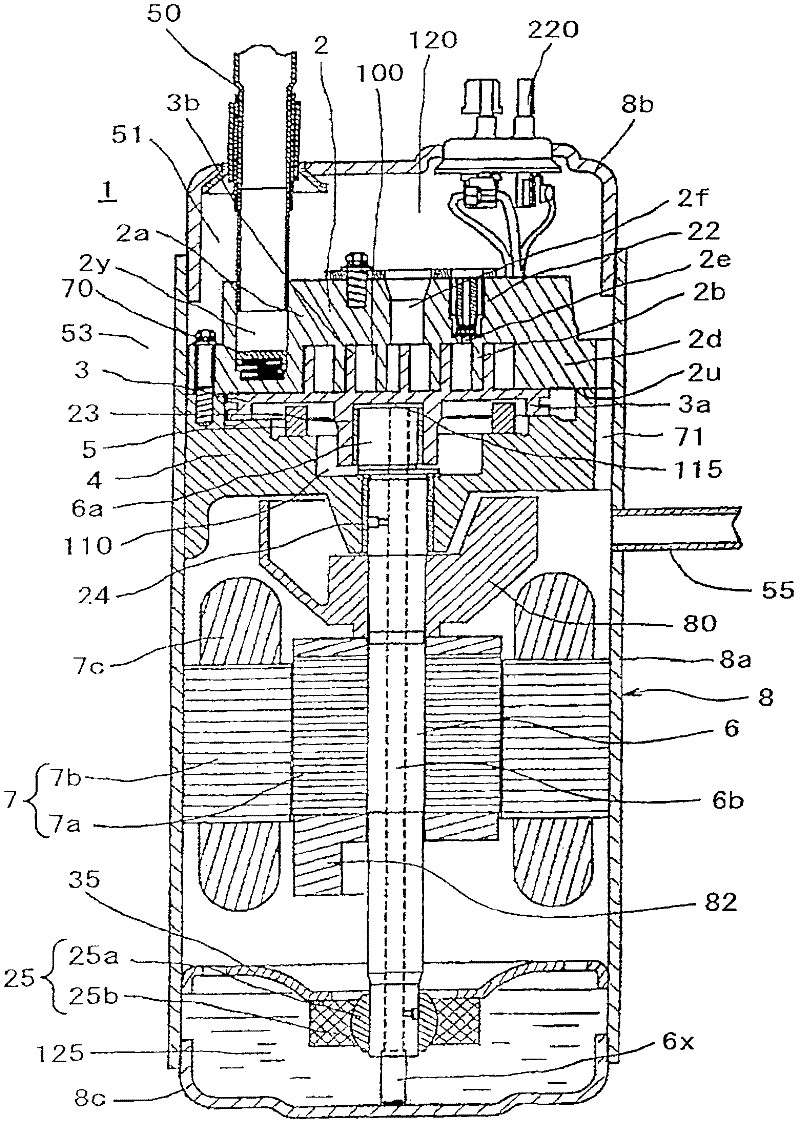

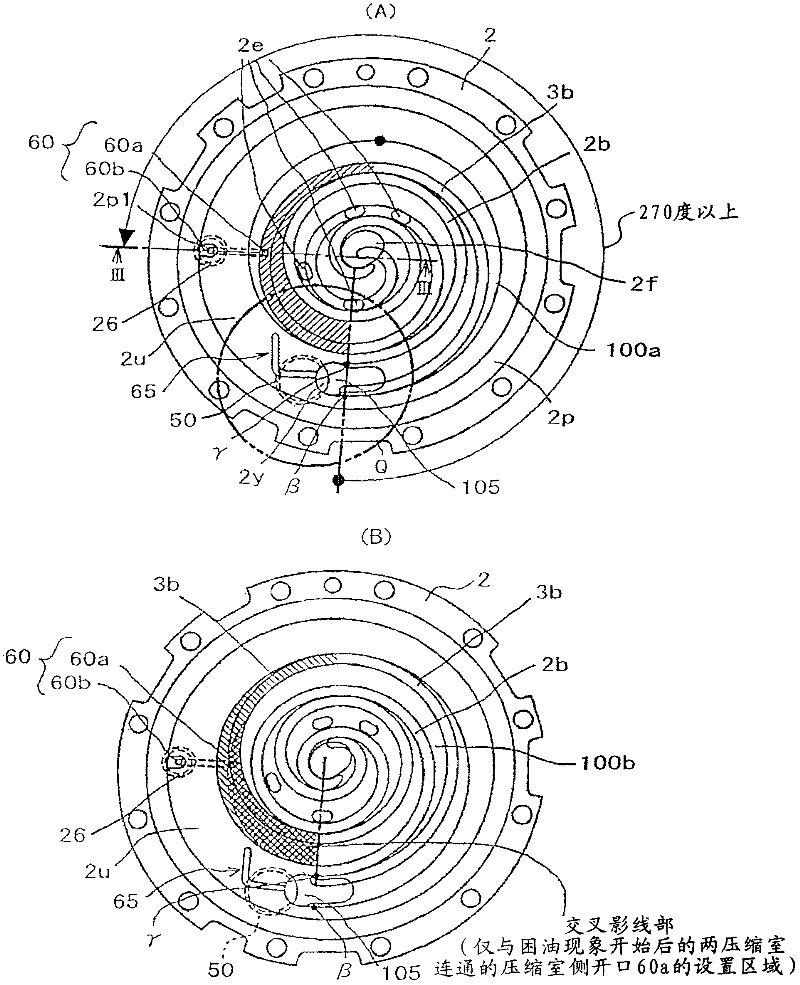

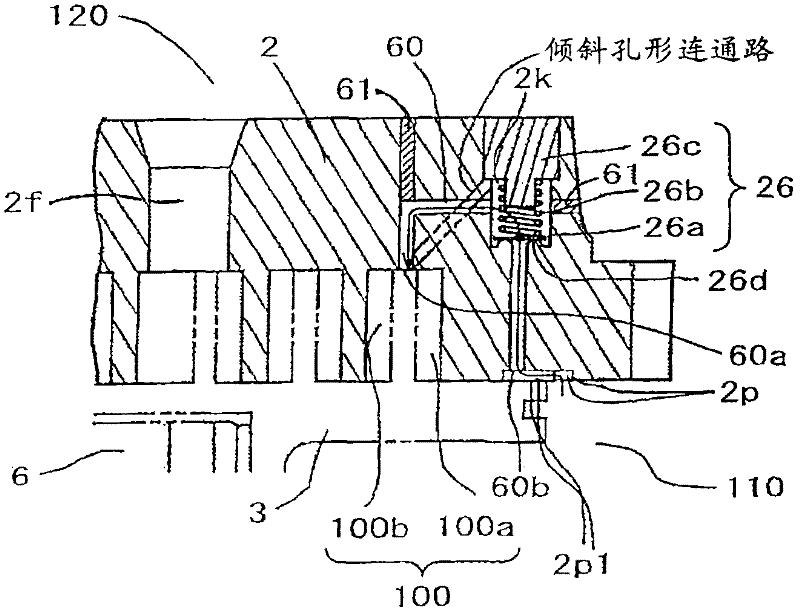

[0064] based on Figure 1 to Figure 6 Example 1 of the present invention will be described. figure 1 is a longitudinal sectional view showing the scroll compressor of this embodiment, figure 2 is true figure 1 The bottom view of the fixed scroll shown is viewed from below, (A) is a diagram including the orbiting scroll wrap (scro-lulap) when the oil trapping phenomenon starts in the compression chamber on the rotating outer line side, and (B) is a diagram At the same time, the figure of the orbiting scroll scroll at the beginning of the oil trapping phenomenon in the compression chamber on the rotating inner line side is included, image 3 yes figure 2 The III-III sectional view of the fixed scroll shown is a diagram for explaining the structure near the back pressure valve. Figure 4 is true figure 1 The orbiting scroll shown is a top view from above, Figure 5 yes Figure 4 The V-V line sectional view of the orbiting scroll shown, Figure 6 will be figure 2The pa...

Embodiment 2

[0103] Next, use Figure 7 Embodiment 2 of the scroll compressor of the present invention will be described. In this embodiment, an externally driven throttle valve is provided in the suction area communicating passage, and the amount of oil supplied from the back pressure chamber to the suction area is adjusted by controlling the externally driven throttle valve. The other structures are basically the same as those of the above-mentioned embodiment 1, so repeated explanations are omitted.

[0104]This Example 2 is further described in detail. The suction area communication path 65' in this embodiment is set to communicate with the back pressure chamber 110 of the scroll compressor 1 and the suction hole 2y of the suction area 105 in the flow path of the working fluid from the suction pipe 50 to the compression chamber 100, and An externally driven throttle valve (flow rate control valve) 65c whose opening can be controlled by a control device 65g provided outside the scroll...

Embodiment 3

[0110] use Figure 8 ~ Figure 10 Embodiment 3 of the scroll compressor of the present invention will be described. Figure 8 is a top view of the orbiting scroll in this embodiment, Figure 9 yes Figure 8 A longitudinal sectional view of the orbiting scroll, is Figure 8 Sectional view of line IX-IX, Figure 10 It is an enlarged view of the vicinity of the suction pipe on the fixed end plate surface of the fixed scroll in this embodiment, which is equivalent to figure 2 A diagram of the Q section. In this embodiment 3, the parts with the same symbols as those in the above-mentioned embodiment 1 represent the same or corresponding parts.

[0111] In this embodiment 3, instead of the rotating end plate oil supply hole 65a in the above-mentioned embodiment 1, a rotating end plate is provided at a position of the rotating end plate 3a in the orbiting scroll 3 facing the fixed end plate surface 2u. Oil supply recessed portion (recessed portion) 65A. In addition, an arc-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com