Method for producing rapamycin fermentation liquid by culturing streptomyces hygroscopicus

A technology of Streptomyces hygroscopicus and rapamycin, which is applied in the field of biomedicine, can solve problems such as unfavorable extraction and purification, low rapamycin fermentation unit, and inability to fully satisfy industrialized production, so as to satisfy industrialized production and be beneficial to extraction. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1100

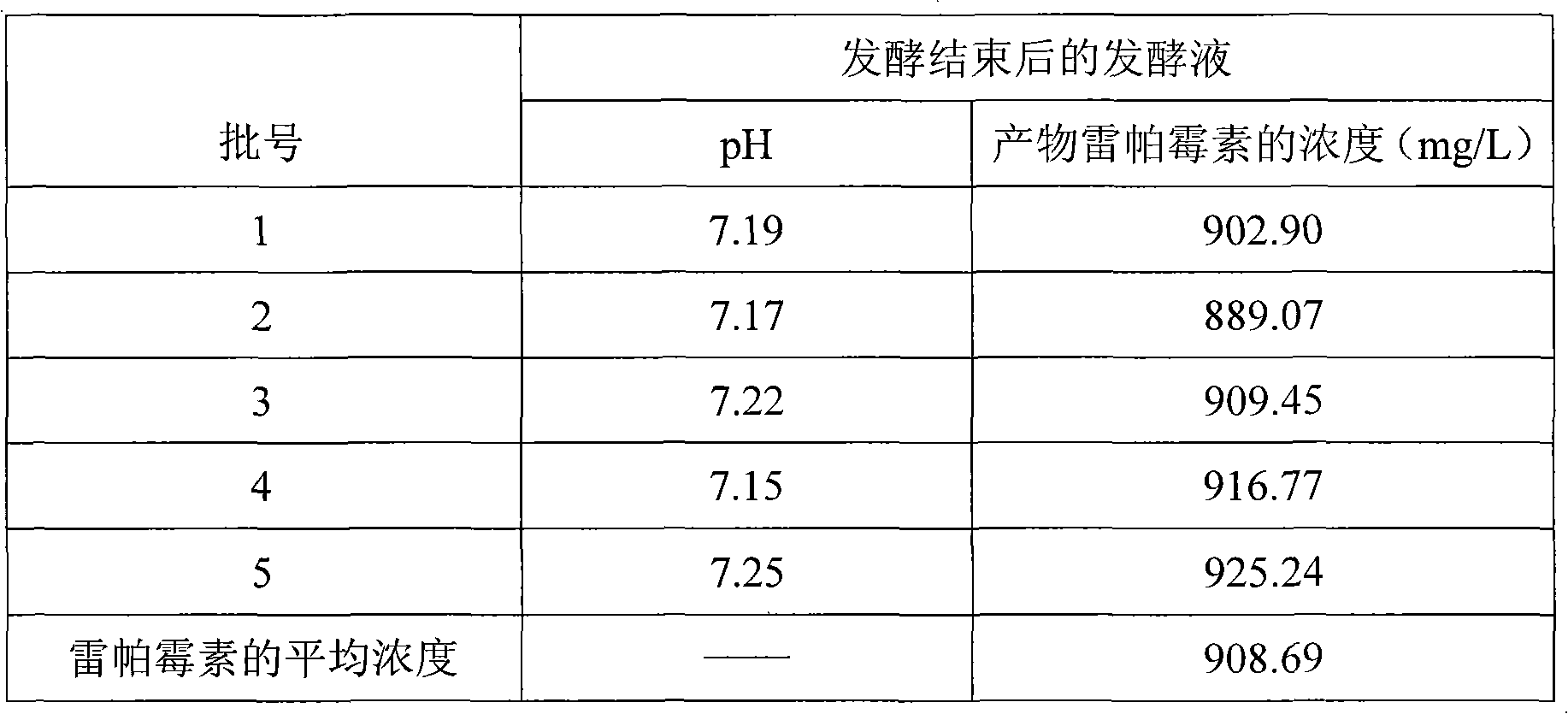

[0035] The fermentation culture of embodiment 1100L fermentor

[0036] (1) Preparation of culture medium

[0037] The formula of the solid medium is: every liter of the solid medium contains 40g of oatmeal, 20g of glucose, 10g of yeast extract, 2g of calcium carbonate and 16g of agar, and the pH is 7.2. Prepare 0.6L.

[0038] The formula of the seed culture medium is: every liter of the seed culture medium contains 40g of soluble starch, 5g of peptone, 10g of yeast extract, 10g of peanut meal, 10g of glycerin and 2g of calcium carbonate, and the pH is 7.0. Prepare 7L.

[0039] The formula of the fermentation medium is: each liter of the fermentation medium contains 13g of corn starch, 10g of soybean cake powder, 6g of peptone, 35g of glucose, K 2 HPO 4 3g, KH 2 PO 4 3g and NaCL1g, calcium carbonate 3g and foam enemy 3g, the pH is 6.9. Prepare 60L.

[0040] (2) Plate culture of Streptomyces hygroscopicus

[0041] After the solid medium is prepared, put it into an Erlen...

Embodiment 2100

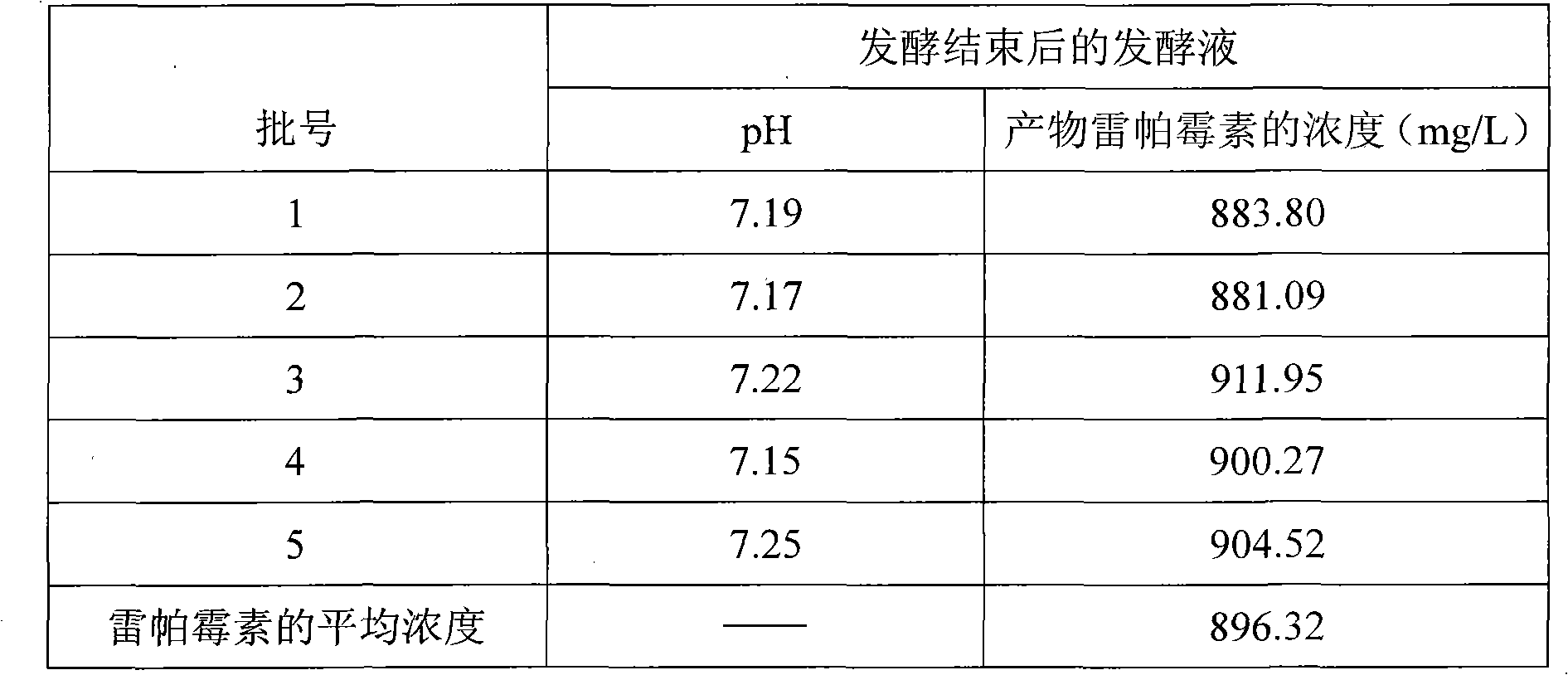

[0053] The fermentation culture of embodiment 2100L fermentor

[0054] (1) Preparation of culture medium

[0055] The formula of the solid medium is: every liter of the solid medium contains 30g of oatmeal, 25g of glucose, 15g of yeast extract, 2g of calcium carbonate and 16g of agar, and the pH is 7.1. Prepare 0.6L.

[0056] The formula of the seed culture medium is: every liter of the seed culture medium contains 30g of soluble starch, 5g of peptone, 7g of yeast extract, 10g of peanut meal, 10g of glycerin, 2g of calcium carbonate, and the pH is 6.9. Prepare 7L.

[0057] The formula of the fermentation medium is: each liter of fermentation medium contains 18g of corn starch, 13g of soybean cake powder, 4g of peptone, 35g of glucose, KH 2 PO 4 4g and NaCL1g, calcium carbonate 3g, foam enemy 4g, pH is 6.5. Prepare 60L.

[0058] (2) Plate culture of Streptomyces hygroscopicus

[0059] After the solid medium is prepared, put it into an Erlenmeyer flask (1x750mL), steriliz...

Embodiment 31000

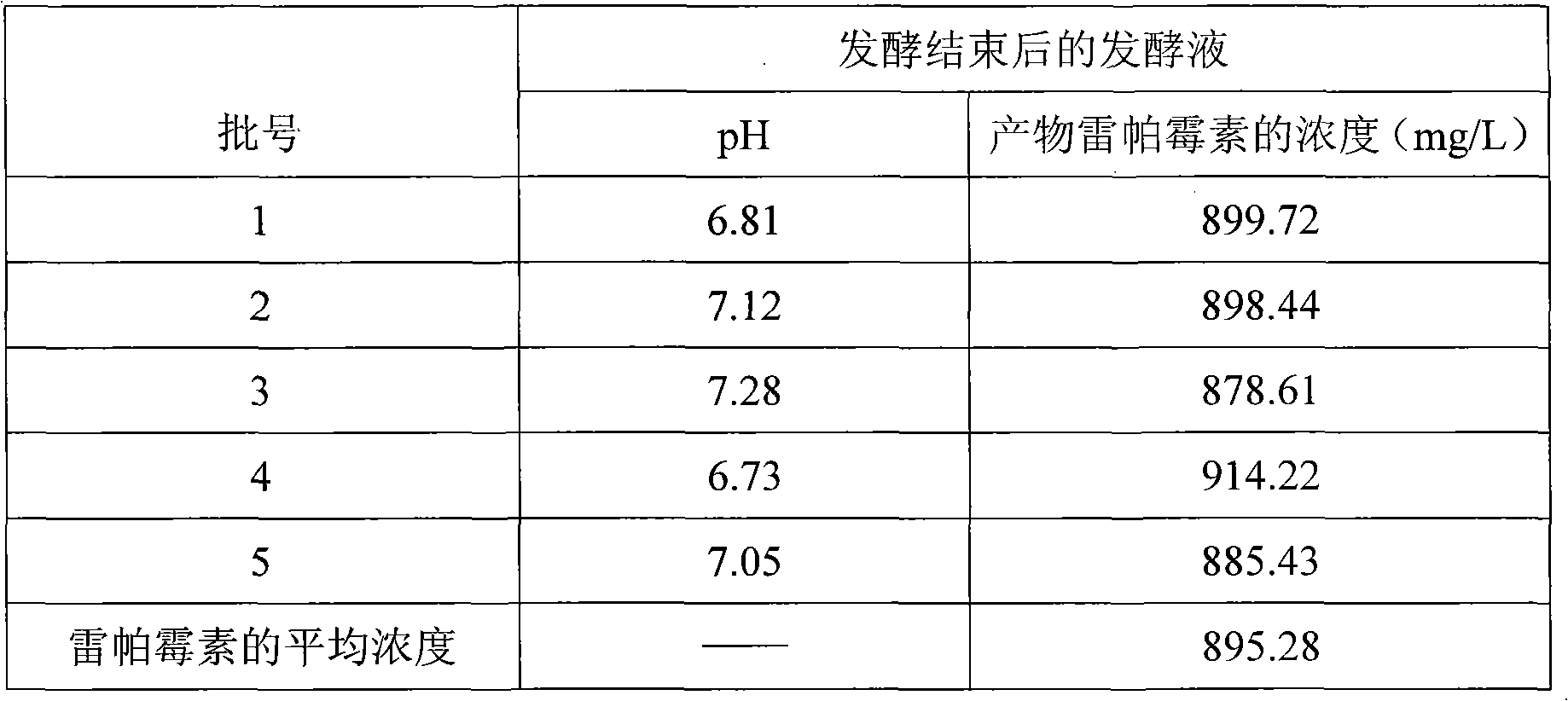

[0071] The fermentation culture of embodiment 31000L fermentor

[0072] (1) Preparation of culture medium

[0073] The formula of the solid medium is: every liter of the solid medium contains 40g of oatmeal, 20g of glucose, 10g of yeast extract, 2g of calcium carbonate and 16g of agar, and the pH is 7.2. Prepare 1L

[0074] The formula of the seed culture medium is: every liter of the seed culture medium contains 40g of soluble starch, 5g of peptone, 10g of yeast extract, 10g of peanut meal, 10g of glycerin and 2g of calcium carbonate, and the pH is 7.0. Prepare 70L

[0075] The formula of the fermentation medium is: each liter of the fermentation medium contains 13g of corn starch, 10g of soybean cake powder, 6g of peptone, 35g of glucose, K 2 HPO 4 3g, KH 2 PO 4 3g and NaCL1g, calcium carbonate 3g and foam enemy 3g, the pH is 6.9. Prepare 700L

[0076] (2) Plate culture of Streptomyces hygroscopicus

[0077] After the solid medium is prepared, put it into an Erlenme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com