Antibacterial biaxially-oriented polylactic acid (BOPLA) film and preparation method thereof

A technology of biaxial stretching and polylactic acid, applied in the field of polylactic acid composition, can solve the problems of complicated preparation process and no use mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

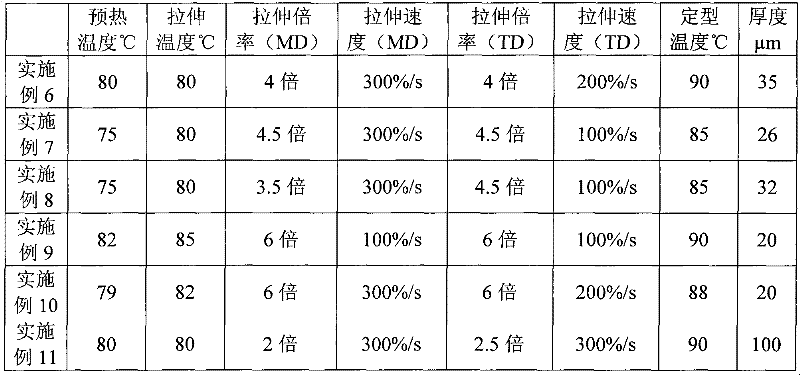

Examples

Embodiment 1

[0056] (1) Weigh 100.0 g (0.465 mol) of polyhexamethylene guanidine propionate (Shanghai Gaoju F3000), add it to 300 mL deionized water solution, stir to dissolve it, and call it solution A; (2) also call it Add 70.0g (0.246mol) of sodium silicate (chemically pure, commercially available) into 300mL of deionized water, stir to dissolve it, and call it solution B; (3) at room temperature (about 25°C), mix solution A and Solution B was mixed and fully stirred for 30 minutes to form solution C; (4) Weigh zinc sulfate ZnSO 4 (Chemically pure, commercially available) 180.0g (0.626mol), slowly poured into solution C, and vigorously stirred for 5min, the precipitate was filtered, dried, and pulverized to obtain polyhexamethylene guanidine propionate / polysilicic acid Zinc composite antibacterial agent (composite antibacterial agent one).

Embodiment 2

[0058] (1) Weigh 100.0 g (0.465 mol) of polyhexamethylene guanidine propionate (Shanghai Gaoju F3000), add it to 300 mL deionized water solution, stir to dissolve it, and call it solution A; (2) also call it Add 100.0 g (0.352 mol) of sodium silicate (chemically pure, commercially available) into 500 mL of deionized water, stir to dissolve it, and call it solution B; (3) mix solution A and solution B, and fully Stir for 1h to form solution C; (4) weigh zinc sulfate ZnSO 4 (Chemically pure, commercially available) 120.0g (0.417mol), slowly poured into solution C, and vigorously stirred for 10min, the precipitate was filtered, dried, and pulverized to obtain polyhexamethylene guanidine propionate / polysilicic acid Zinc composite antibacterial agent (composite antibacterial agent two).

Embodiment 3

[0060] (1) Weigh 100.0g (0.635mol) of polyhexamethyleneguanidine hydrochloride (Shanghai Gaoju F1000), add it to 300mL deionized water solution, stir to dissolve it, and call it solution A; Sodium silicate (chemically pure, commercially available) 150.0g (0.528mol), was added to 600mL deionized water, stirred to dissolve, called solution B; (3) at room temperature (about 25 ° C), solution A and Solution B was mixed and fully stirred for 1.5h to form solution C; (4) Weigh calcium nitrate Ca(NO 3 ) 2 (Chemically pure, commercially available) 120.0g (0.508mol), slowly poured into solution C, and vigorously stirred for 10min, the precipitate was filtered, dried, and pulverized to obtain polyhexamethyleneguanidine hydrochloride / polysilicic acid Calcium compound antibacterial agent (composite antibacterial agent three).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com