Load type metallocene catalyst and preparation method thereof

A technology of metallocene catalyst and metallocene compound, which is applied in the field of supported metallocene catalyst and its preparation, and can solve the problem of low ethylene polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

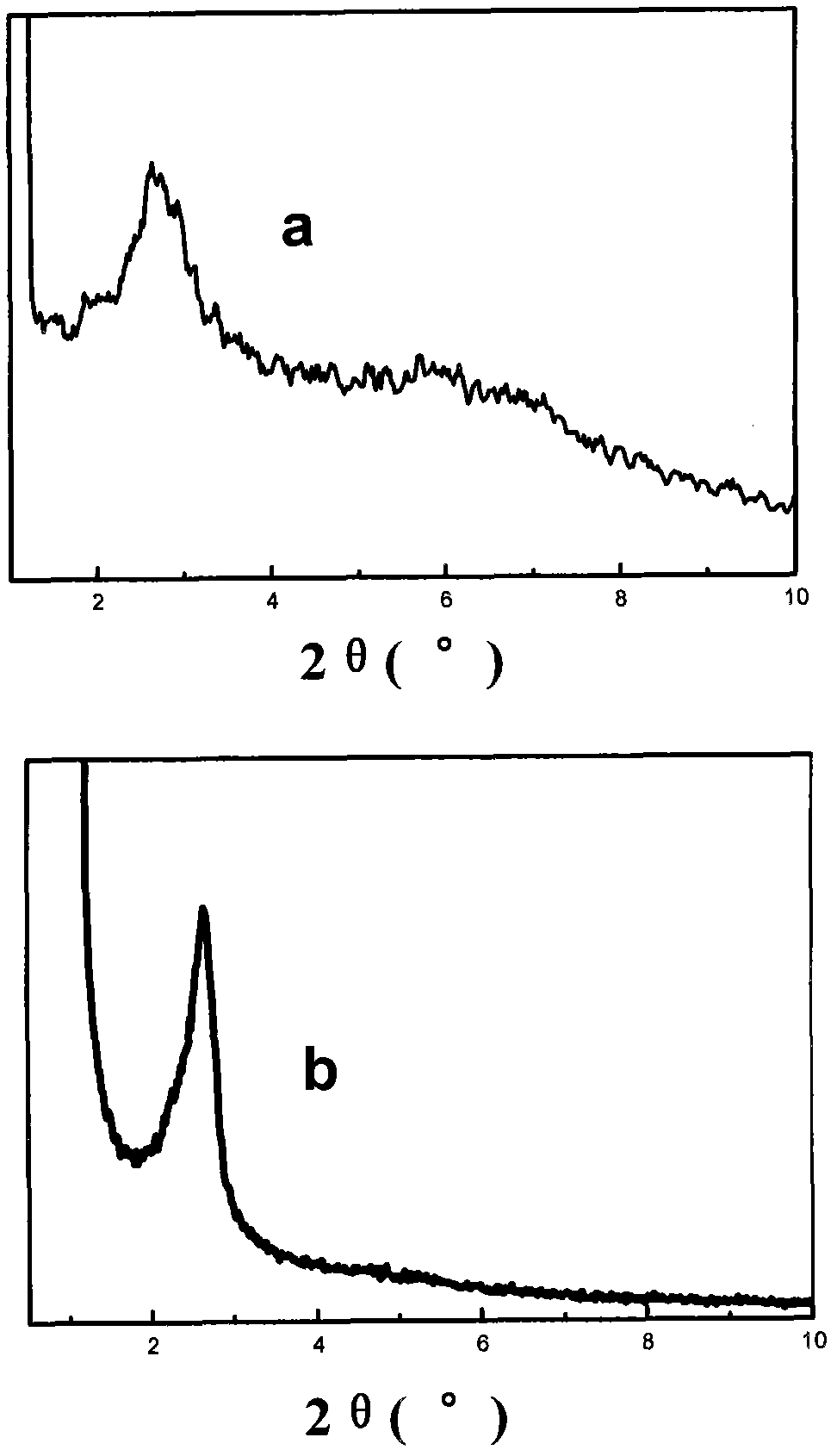

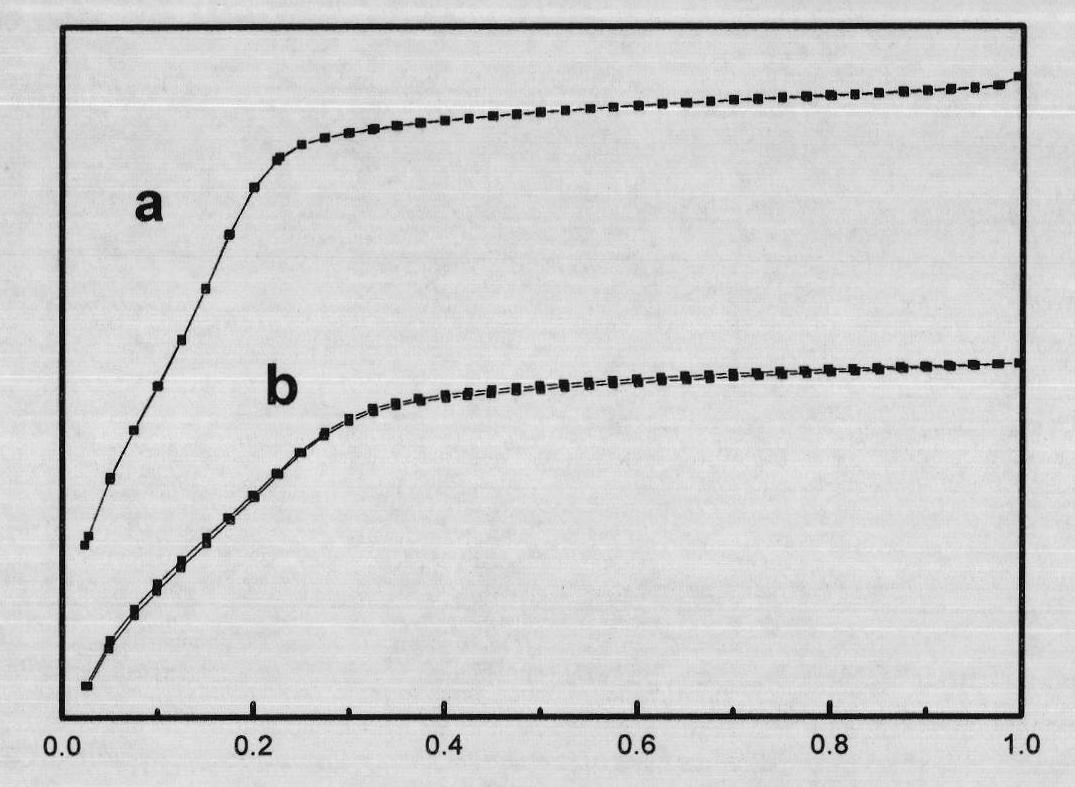

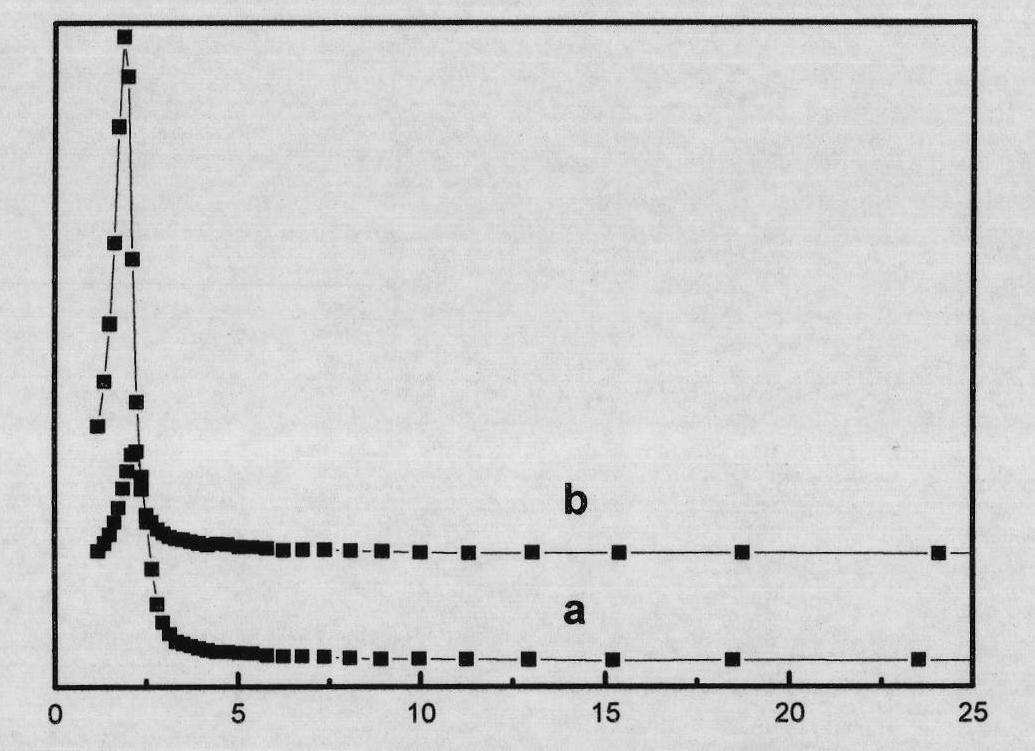

[0045] According to another embodiment of the present invention, the spherical mesoporous silica carrier can be prepared by a method comprising the following steps: in the presence of a templating agent, contacting a silicate ester with an acidic aqueous solution, and mixing the resulting mixture Crystallization under crystallization conditions, the resulting crystallization product is heated to remove the template agent, the template agent is hexadecyltrimethylammonium bromide and polyethylene glycol octylphenyl ether (also known as Triton X-100).

[0046] According to the present invention, the molar ratio of the acid in the acidic aqueous solution and the water in the acidic aqueous solution can be within a certain range Change, preferably, the molar ratio of the acid and water in the silicate, cetyltrimethylammonium bromide, polyethylene glycol octylphenyl ether (Triton X-100), acidic aqueous solution 1: 0.1-0.6: 0.1-0.5: 5-50: 100-500, more preferably, the silicate, cety...

Embodiment 1

[0066] This example is used to illustrate the supported metallocene catalyst provided by the present invention and its preparation method.

[0067] 1.5 g of CTAB (hexadecyl trimethyl ammonium bromide), 1.5 mL of polyethylene glycol octyl phenyl ether (Triton-X100, purchased from Shanghai Sangon Bioengineering Co., Ltd., product number TB0198) were mixed with Contact with a hydrochloric acid solution containing 29.6 grams of concentrated hydrochloric acid (concentration of 37% by weight) and 75 grams of water, stirring at 40 ° C until CTAB is completely dissolved, adding 4.35 grams of tetraethyl orthosilicate to the above solution, at 40 ° C. Stir for 15 minutes, stand at 40°C for 24 hours, filter, wash and dry, then calcinate at 600°C for 24 hours to remove the template agent to obtain the carrier JKQ;

[0068] Under nitrogen protection, JKQ was calcined at 400 °C for 10 hours to remove hydroxyl groups and residual moisture, thereby obtaining thermally activated JKQ;

[0069]...

experiment Embodiment 1

[0081] This experimental example is used to illustrate the catalytic activity of the supported metallocene catalyst according to the present invention.

[0082] In a 2-liter stainless steel autoclave, replace three times with nitrogen and ethylene, then add 200 ml of hexane, raise the temperature of the kettle to 80°C, and then add 800 ml of hexane, and with the addition of hexane, add 2 ml of hexane 1 mol / L of triethylaluminum (TEA, purchased from Zhejiang Freed Chemical Co., Ltd.) in hexane, followed by adding 43.3 mg of JKQ-BU, and feeding ethylene to raise the pressure to 1.0 MPa and maintain it at 1.0 MPa , and react at 70 °C for 1 hour. Obtain 213 grams of polyethylene granular powder, the bulk density (BD) of this polyethylene granular powder is 0.306g / mL, melt index MI 2.16 =0.026g / 10min. It was determined by calculation that the efficiency of the catalyst was 4919 g PE / g cat h (ie, 1.1 × 10 9 g PE / (mol Zr h)).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com