Preparation method of hydrogenation catalyst composition

A technology of hydrogenation catalyst and composition, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., which can solve problems such as difficulty in forming bulk catalysts and achieve bonding Reinforcement, large pore volume, and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

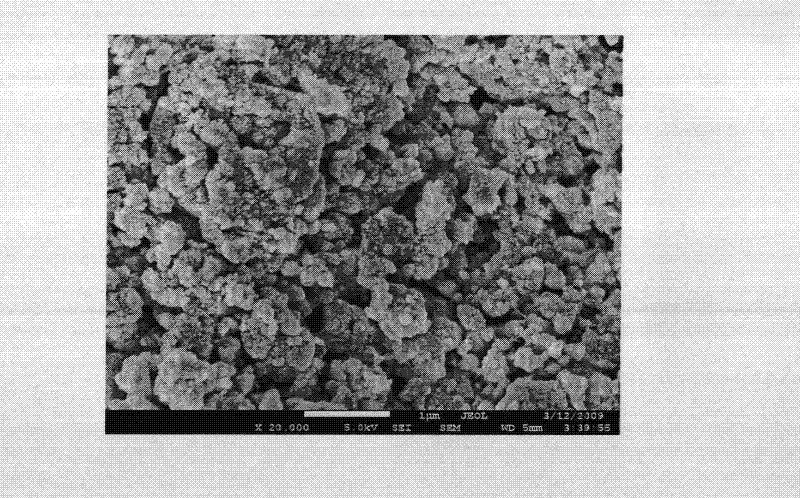

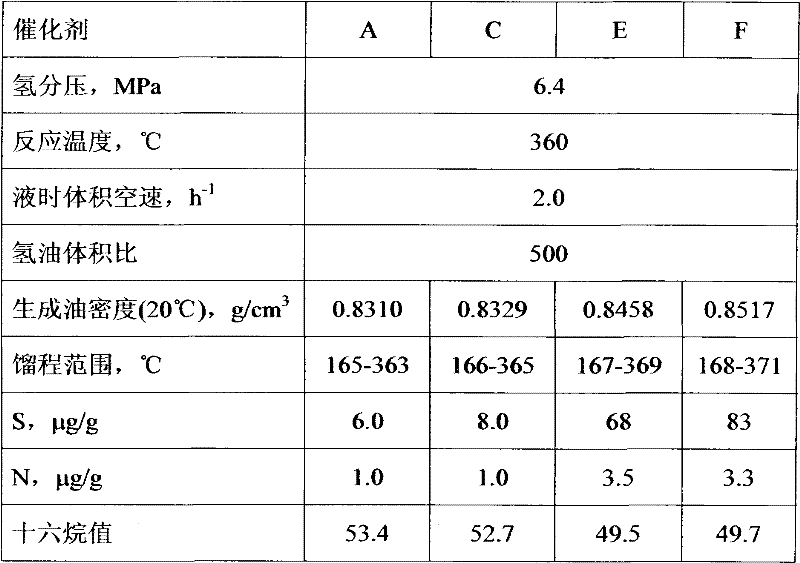

Embodiment 1

[0029] Add 500mL of water to the dissolving tank 1, add 40g of nickel chloride and 46g of ammonium metatungstate respectively to dissolve, prepare an acidic working solution A, add 500mL of water to the dissolving tank 2, then add 30 grams of sodium metaaluminate to dissolve, and prepare an alkali. Sex Work Solution B. 350 mL of water was added to the reaction tank, and the temperature was raised to 45°C. With stirring, mix solution A, solution B and CO 2 Add cocurrent into the reaction tank to form gel, CO 2 The concentration is 40v%, the gel-forming temperature is 45°C, the gel-forming time is 1 hour, and the pH value of the gel-forming slurry is 8.5. Add CO during the gelation process 2 Total amount of gas and Al in alkaline working solution B 2 O 3 The molar ratio was 3.5. Aging for 2 hours after gel formation. Then filter, add 600ml of purified water and 12.4g of molybdenum trioxide to the filter cake, beat and stir evenly, filter, dry the filter cake at 80 °C for ...

Embodiment 2

[0031] According to the method of Example 1, add nickel chloride, ammonium metatungstate and zirconium oxychloride to the dissolving tank 1 according to the component content ratio of the catalyst B in Table 1 to prepare the acidic working solution A, then add the dissolving tank 1 to the solution A. 2 Add sodium metaaluminate alkaline working solution B. 350 mL of water was added to the reaction tank, and the temperature was raised to 40°C. With stirring, mix solution A, solution B and CO 2 Add cocurrent into the reaction tank to form gel, CO 2 The concentration is 45v%, the gel-forming temperature is 40°C, the gel-forming time is 1.5 hours, and the pH value of the gel-forming slurry is 7.5. Add CO during the gelation process 2 Total amount of gas and Al in alkaline working solution B 2 O 3 The molar ratio was 4.0. Aging for 1.5 hours after gel formation. Then filter, add 500ml of purified water and 10.3g of molybdenum trioxide to the filter cake, beat and stir evenly,...

Embodiment 3

[0033] According to the method of embodiment 1, according to the component content ratio of catalyst C in table 1, in dissolving tank 1, add nickel chloride, ammonium metatungstate and phosphoric acid to prepare acid working solution A, then add in dissolving tank 2 Sodium metaaluminate alkaline working solution B. 350 mL of water was added to the reaction tank, and the temperature was raised to 50°C. With stirring, mix solution A, solution B and CO 2 Add cocurrent into the reaction tank to form gel, CO 2 The concentration is 35v%, the gel-forming temperature is 50°C, the gel-forming time is 1.5 hours, and the pH value of the gel-forming slurry is 8.0. Add CO during the gelation process 2 Total amount of gas and Al in alkaline working solution B 2 O 3 The molar ratio was 3.0. Aging for 2.0 hours after gel formation. Then filter, add 500ml of purified water and 11.2g of molybdenum trioxide to the filter cake, beat and stir evenly, and filter the filter cake. After calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com