Method for forming side wall and storage unit formed thereby

A technology of side walls and right-angled triangles, applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as difficulty in controlling device threshold voltage, reducing device performance, and short-channel effect of devices, so as to improve writing speed , device performance maintenance, and the effect of increasing the substrate current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

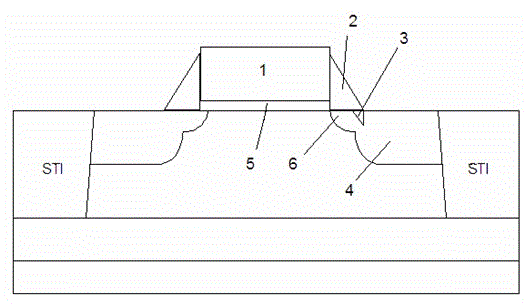

[0019] The present invention provides a method for forming sidewall spacers. The method includes: forming sidewall spacers of the gate structure on a semiconductor substrate having a gate structure and source / drain prefabricated regions; etching the formed sidewall spacers, Forming lower wide and upper narrow sidewalls; heavily doping the source and drain prefabricated regions with predetermined ions to form source and drain regions, and the predetermined ions used for heavily doping penetrate into the bottom of the sidewalls.

[0020] In the present invention, after the usual side wall etching process, an etching process for modifying the side wall profile is added, and the improved side wall profile is formed to form a right-angled triangular side wall. When the source and drain are heavily doped and implanted, some ions with higher energy will pass through the thinner sidewall regions and be implanted into the substrate. The implantation depth of this part of the ions is relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com