Asphalt foaming machine used for preparing foamed asphalt

A technology of foamed asphalt and foaming machine, which is applied in the field of engineering material machinery preparation, can solve the problems of high cost, poor operation stability, easy blockage and difficult cleaning of nozzles, etc., and achieve low manufacturing and maintenance costs, simple equipment structure, debugging and The effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

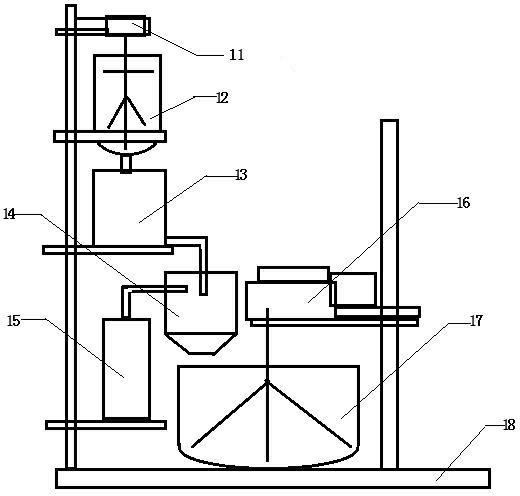

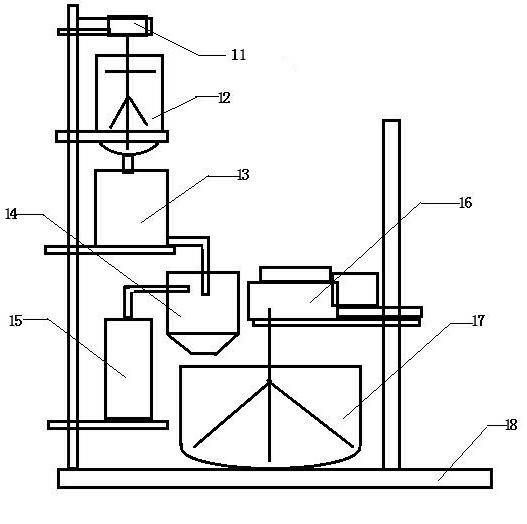

[0019] Such as figure 2 , an asphalt foaming machine for preparing foamed asphalt, comprising a temperature-regulating asphalt mixing pot 12 with a mixer 11, the asphalt preheated to a fluid state is loaded into the temperature-regulating asphalt mixing pot 12, and the temperature-regulating asphalt mixing pot 12 can stabilize the asphalt in it at the set temperature, and the temperature-adjusting asphalt mixing pot 12 is connected to the inlet of the asphalt gear pump 13 through the asphalt conduit, and the outlet pipe of the asphalt gear pump 13 is connected to the asphalt foaming cavity 14. At the same time, the water pump And the air pump 15 is connected with the asphalt foaming cavity, the lower outlet of the asphalt foaming cavity is opposite to the asphalt mixing pot 17, and a high-power mixer 16 is also arranged above the asphalt mixing pot to stir the asphalt mixture .

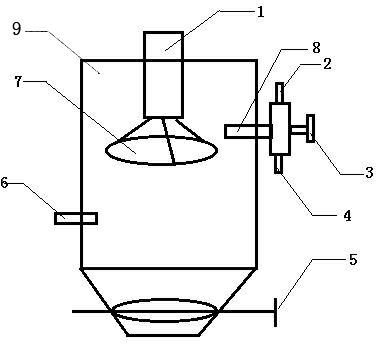

[0020] Such as figure 1 , the asphalt foaming cavity includes a main cavity 9, and the upper pa...

Embodiment 2

[0026] 1. Heat the AH-70 asphalt to 110°C in an oven to make the asphalt into a liquid state;

[0027] 2. Turn on the power of the asphalt foaming machine, preheat its heating system, set the temperature of the temperature-adjusted asphalt mixing pot to 120°C, set the temperature of the asphalt gear pump and asphalt conduit to 150°C, turn on the air pump, and adjust the temperature in the asphalt foaming cavity The atomization effect of foaming water at the pressure water atomization nozzle;

[0028] 3. Set the system temperature again, increase the temperature of the test asphalt in the whole system, pour the liquid asphalt into the temperature-adjusted asphalt mixing pot on the upper part of the asphalt foaming machine, continue stirring and heating the asphalt to 150°C, at this temperature, the asphalt test The sample is marked as A;

[0029] 4. Turn on the asphalt gear pump switch, the hot asphalt will enter the asphalt foaming chamber from the temperature-adjusted asphal...

Embodiment 3

[0036] 1. Heat the AH-70 asphalt to 110°C in an oven to make the asphalt into a liquid state;

[0037]2. Turn on the power of the asphalt foaming machine, preheat its heating system, set the temperature of the temperature-adjusted asphalt mixing pot to 120°C, set the temperature of the asphalt gear pump and asphalt conduit to 150°C, turn on the air pump, and adjust the temperature in the asphalt foaming cavity The atomization effect of foaming water at the pressure water atomization nozzle;

[0038] 3. Pour liquid asphalt into the heating and stirring pot on the upper part of the asphalt foaming machine, continue to stir and heat the asphalt to 160°C, and record the asphalt sample at this temperature as B;

[0039] 4. Turn on the asphalt gear pump switch, the hot asphalt will enter the asphalt foaming chamber from the temperature-adjusted asphalt mixing pot under the asphalt gear pump, and turn on the water pump switch at the same time, so that the hot asphalt and its mass are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com