Stripping method of thin-film material

A thin film material and thin film technology, applied in the field of thin film material peeling, can solve the problems of high production cost, poor physical properties of the thin film, and reduced nonlinear optical coefficient of the lithium niobate thin film, so as to reduce the production cost and improve the quality of the thin film. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

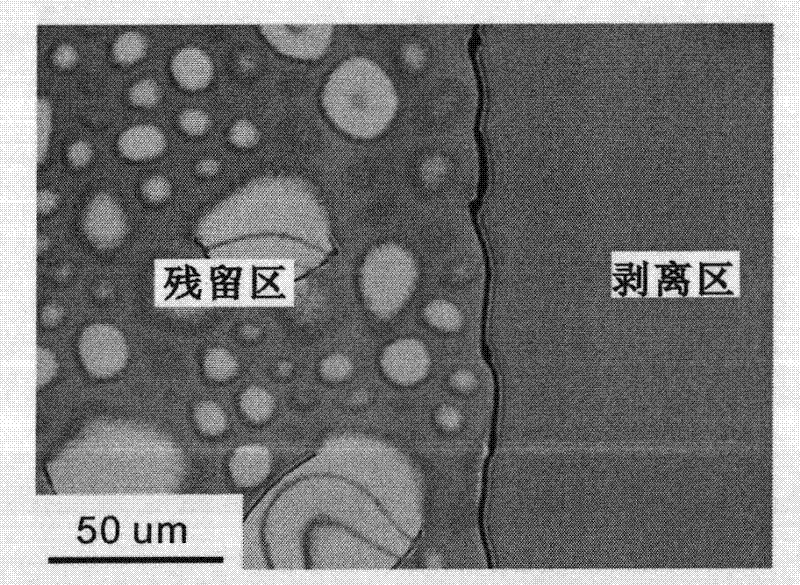

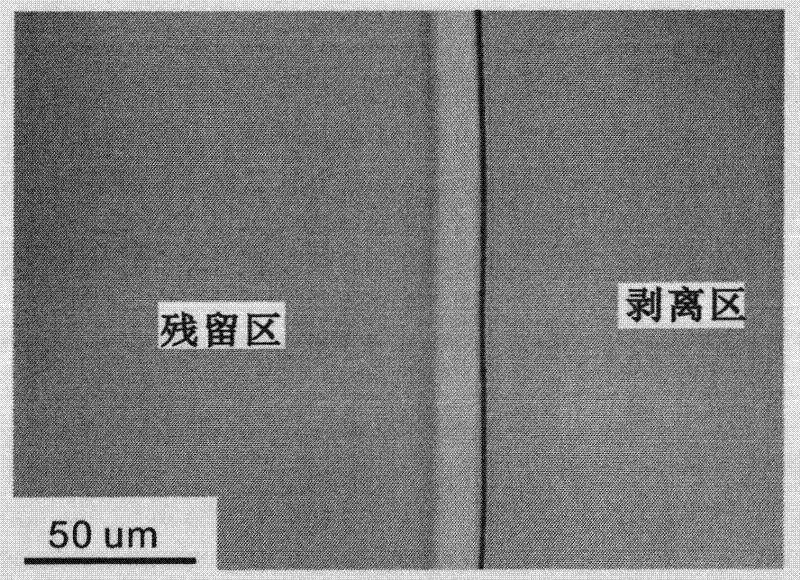

[0010] way 1

[0011] The lithium niobate (or lithium tantalate) wafer A is implanted with helium ions, and the implantation dose can be 1×10 16 ions / cm 2 to 4×10 16 ions / cm 2 In between, deposit a layer of silicon dioxide on the surface of another piece of lithium niobate crystal (or lithium tantalate) piece B and then polish it. After bonding A and B, raise the temperature to about 170°C and stay for 10 hours to make the wafer reach the best bonding strength, and then within 10 minutes, raise the temperature to 230°C. The internal stress caused by this temperature change makes the film Lithium niobate (or lithium tantalate) film is obtained after polishing.

[0012] way 2

[0013] The lithium niobate (or lithium tantalate) wafer A is implanted with helium ions, and the implantation dose can be 1×10 16 ions / cm 2 to 4×10 16 ions / cm 2 In between, deposit a layer of silicon dioxide on the surface of another lithium niobate (lithium tantalate) wafer B and then polish it....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com