Preparation method of immobilized enzyme by applying amphiphilic porous hollow carbon microspheres

An immobilized enzyme, amphiphilic technology, applied in the direction of immobilization on or in an inorganic carrier, can solve the problems of high immobilization cost, complicated and complicated operation process, etc., to prevent the damage of the enzyme from external factors, and to have a wide range of raw material sources. , The effect of improving operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Application of Amphiphilic Hollow Carbon Microspheres to Immobilize Lipase

[0023] (1) Preparation of amphiphilic hollow carbon microspheres

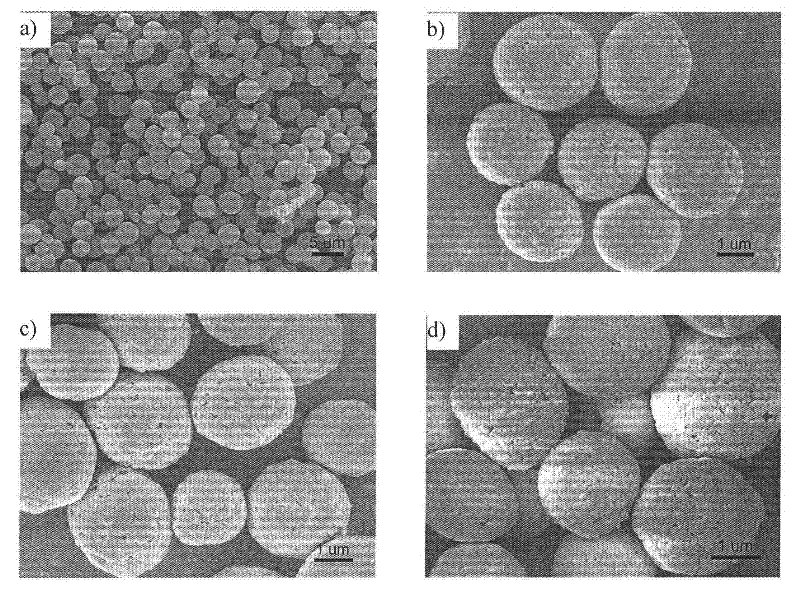

[0024] Weigh 20g of brewer's yeast (Saccharomyces cerevisiae) (trade name is high-temperature resistant high-activity brewer's yeast, purchased from Angel Yeast Co., Ltd., catalog number 80000012), dispersed in 100ml of 0.01mol / L adipaldehyde aqueous solution, and then transferred Put the reaction kettle in a constant temperature box and heat at 180°C for 14h. After the reaction, collect the precipitate, wash the obtained precipitate with deionized water, and then dry it at 20°C for 24h to obtain amphiphilic hollow carbon microspheres. Scanning electron microscope (SEM) topography photos of amphiphilic hollow carbon microspheres are shown in figure 1 , the particle size is 2-4 microns, and the pore size is >50nm.

[0025] (2) Preparation of immobilized lipase

[0026] Free lipase (protein): the trade name is Lipozym...

Embodiment 2

[0041] Example 2 Application of Amphiphilic Hollow Carbon Microspheres to Immobilize Lipase

[0042] (1) Preparation of amphiphilic hollow carbon microspheres

[0043] With the step (1) of embodiment 1.

[0044] (2) Preparation of immobilized lipase

[0045] Free lipase (protein): purchased from Sigma, model L3126.

[0046] Get 50 mg of amphiphilic hollow carbon microspheres prepared in step (1), and evenly disperse them into 2 mL of lipase solution (composed of free lipase and 0.02 mol / L acetic acid-sodium acetate buffer at pH 6.0; lipase concentration is 4 mg / L mL), shake at 100rpm for 12h at 4°C, centrifuge, wash the carbon microspheres loaded with lipase for 2-3 times with 10mL 0.02mol / L acetic acid-sodium acetate buffer solution of pH 6.0, and the protein loading capacity is 15.89 mg / g of immobilized lipase.

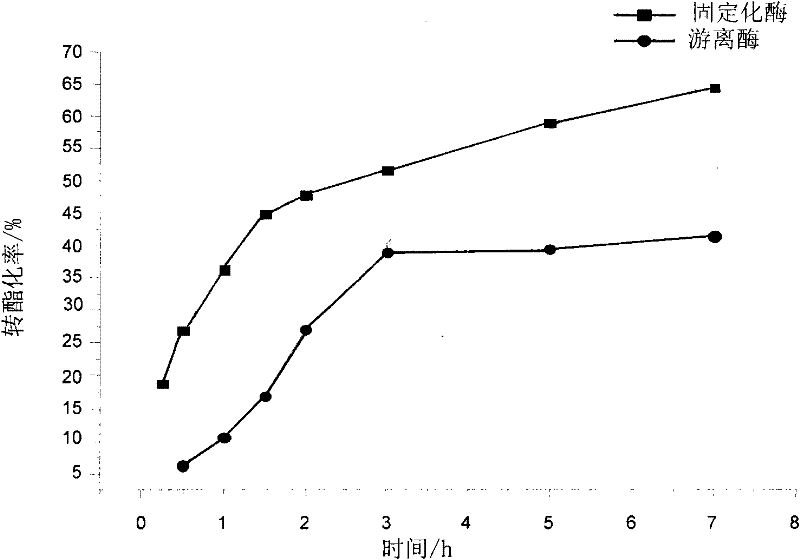

[0047] (3) Catalytic performance

[0048] Dissolve 200mg of nitrophenyl palmitate (p-NPP) in 8mL of 1g / 100mL n-butanol in n-heptane solution, then add 50mg of ...

Embodiment 3

[0050] Example 3, application of amphiphilic hollow carbon microspheres to immobilize catalase

[0051] (1) Preparation of amphiphilic hollow carbon microspheres

[0052] Weigh 20g of brewer's yeast (Saccharomyces cerevisiae) (trade name is high-temperature resistant high-activity brewer's yeast, purchased from Angel Yeast Co., Ltd., catalog number 80000012), dispersed in 100ml of 0.01mol / L adipaldehyde aqueous solution, and then transferred Put the reaction kettle in a constant temperature box and heat it at 240°C for 8h. After the reaction, collect the precipitate, wash the obtained precipitate with deionized water, and then dry it at 20°C for 24h to obtain amphiphilic hollow carbon microspheres (particles) The diameter is 2-4 microns, and the pore diameter is > 50nm).

[0053] (2) Preparation of immobilized catalase

[0054] Free catalase (protein): solid powder, purchased from Sigma, USA, product number is C9322.

[0055] Get 50 mg of the amphiphilic hollow carbon micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com