Solid fermentation bioreactor

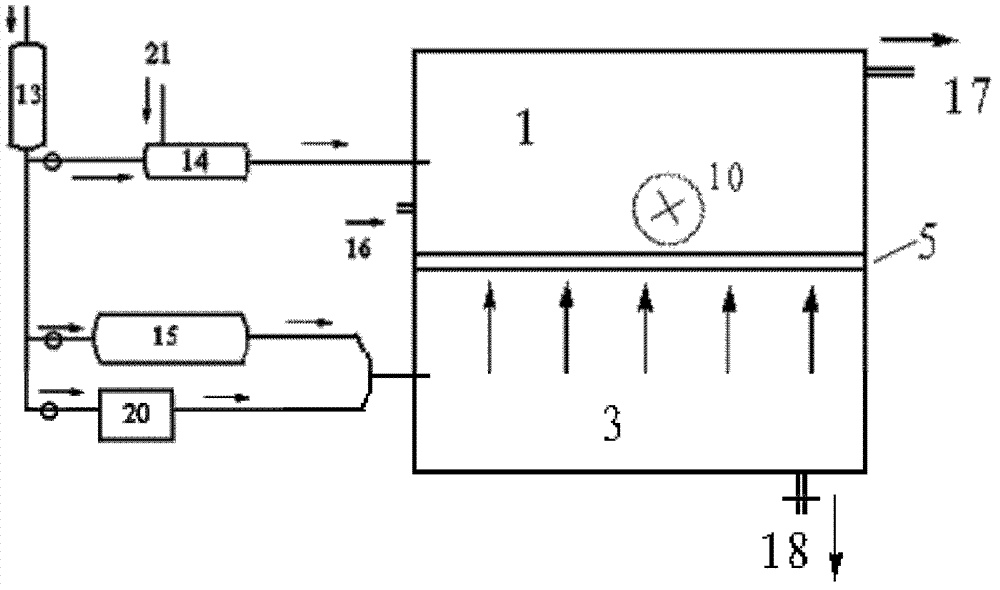

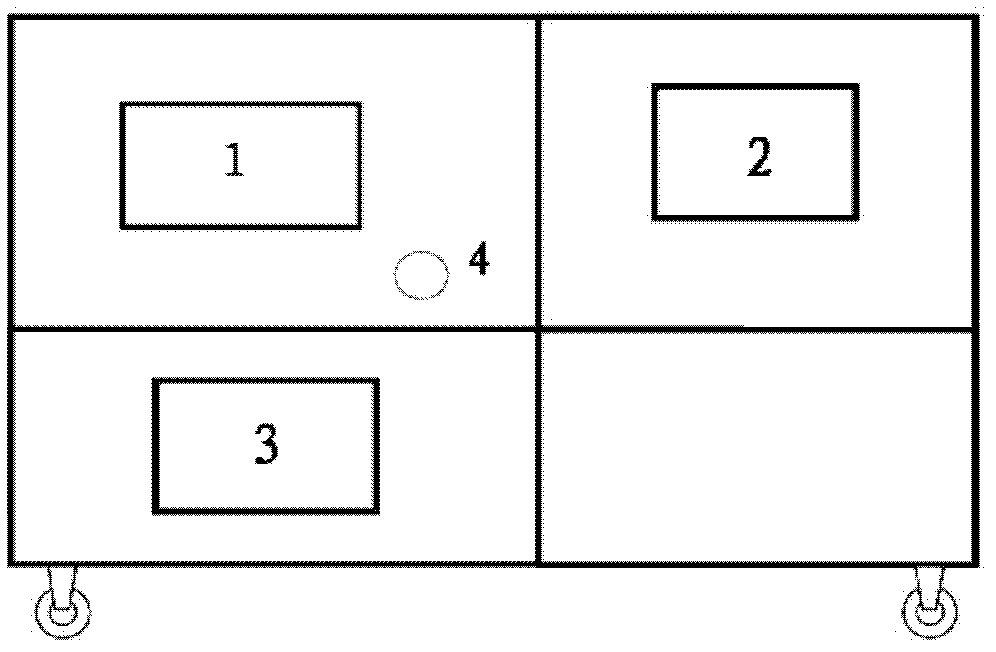

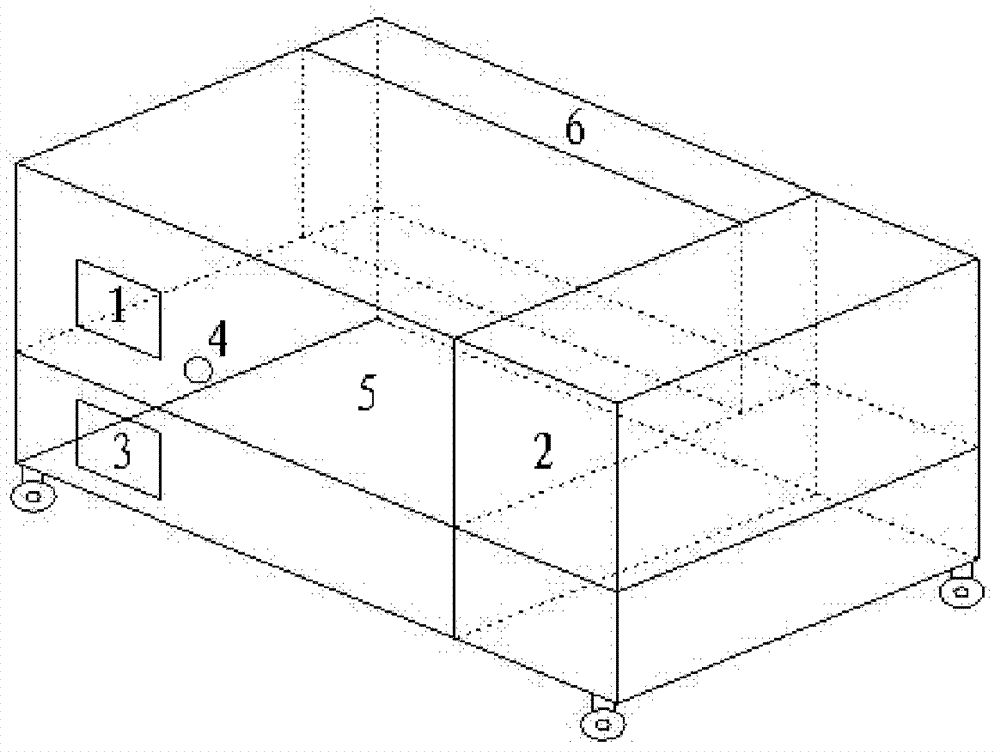

A bioreactor, solid-state fermentation technology, applied in solid-phase fermentation bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problems of fermentation repeatability and poor fermentation effect, Fermentation conditions are difficult to control, mass transfer and heat transfer are not uniform, etc., to achieve the effect of isolating the entry of external pollutants, saving manpower and improving fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Following is main raw material with kelp slag, utilizes above-mentioned solid-state fermentation device to produce Bacillus thuringiensis (Bt) biopesticide, sets forth the method utilizing this solid-state fermentation bioreactor to carry out solid-state fermentation:

[0071] (1) Dried kelp, crushed to 40 mesh, added water to adjust the initial water content to 75%, adjusted the pH to 7.0-7.4, sterilized by moist heat for 20-30 minutes, and cooled to about 30°C;

[0072] (2) Bacterial strain expansion culture: pick a ring of Bacillus thuringiensis bacterial lawn from the slant medium of Bacillus thuringiensis, inoculate in 100mL sterilized beef extract peptone liquid medium (beef extract 0.3%, peptone 1%, NaCl 0.2%, pH 7.0-7.2), for shake flask culture. The culture conditions are: temperature 30°C, rotation speed 200 rpm, culture for 7-8 hours, as Bt bacteria seed liquid;

[0073](3) Solid-state fermentation: start the fermentation equipment, and sterilize by ultravio...

Embodiment 2

[0077] Taking bran as the main raw material, the above-mentioned solid-state fermentation device is utilized to produce metarhizium anisopliae biopesticides, and the method for utilizing this solid-state fermentation bioreactor to carry out solid-state fermentation is set forth below:

[0078] (1) Add water to the bran to adjust the initial water content to 60%, adjust the pH to 7.0, sterilize with damp heat for 20 to 30 minutes, and cool to about 26°C;

[0079] (2) Strain expansion culture: seed culture was added to 250mL Erlenmeyer flask with 100mL of culture solution, after sterilization, inoculated with 3mL of Metarhizium anisopliae spore liquid, at 26°C, 150r / min shaking culture for 3 days, then used as Metarhizium anisopliae seed liquid;

[0080] (3) Solid-state fermentation: start the fermentation equipment, and sterilize by ultraviolet lamp irradiation for 30 minutes. Set the temperature, humidity, and ventilation as temperature 26°C, humidity 80%, and air flow 1:1 to ...

Embodiment 3

[0084] Below with asparagus leftovers as main raw material, utilize above-mentioned solid-state fermentation device to produce Beauveria bassiana biological pesticide, set forth the method utilizing this solid-state fermentation bioreactor to carry out solid-state fermentation:

[0085] (1) Add water to the asparagus leftovers to adjust the initial water content to 60-65%, adjust the pH to 8.0, sterilize with moist heat for 20-30 minutes, and cool to about 30°C;

[0086] (2) Strain expansion culture: 50ml of seed culture medium was installed in a 250ml Erlenmeyer flask, inoculated with an activated slant, and cultivated on a shaking table at a temperature of 27°C and a rotating speed of 200r / min for 48h;

[0087] (3) Solid-state fermentation: start the fermentation equipment, and sterilize by ultraviolet lamp irradiation for 30 minutes. Set the temperature, humidity, and ventilation to 27°C and 85% humidity respectively. After the system stabilizes for 10 minutes, inoculate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com