Crosslinkable poly-(3,4-ethylenedioxythiophene) aqueous dispersoid and preparation method thereof

A technology of ethylenedioxythiophene and dispersion is applied in the field of cross-linkable poly(3,4-ethylenedioxythiophene) aqueous dispersion and its preparation, which can solve the problems of non-conductivity, application limitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

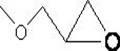

Image

Examples

Embodiment 1

[0063] Example 1 Preparation of poly(3,4-ethylenedioxythiophene) (ie PEDOT) aqueous dispersion Ⅰ

[0064] The template and dopant in PEDOT aqueous dispersion Ⅰ are functionalized sodium polystyrene sulfonate and end-capped non-ionic waterborne polyurethane copolymer, wherein the functionalized sodium polystyrene sulfonate is hydroxyethyl acrylate and styrene The molar ratio of sodium sulfonate is 1:4 copolymer, the ratio of the amount of initiator to the total molar amount of the two monomers is 0.001:1; the capped nonionic waterborne polyurethane R (NCO / OH) = 1.1, and the PEG content is 90% , the mass ratio of functionalized sodium polystyrene sulfonate to capped non-ionic waterborne polyurethane copolymer is 1:1; the mass ratio of template and dopant to EDOT is 0.1:1; during the preparation of aqueous dispersion, oxidant, catalyst The molar ratios to EDOT are 1.5:1 and 0.005:1, respectively.

[0065] Concrete preparation method and steps are as follows:

[0066] 1. SSS (8...

Embodiment 2

[0075] Example 2 (Preparation of PEDOT aqueous dispersion II)

[0076] The template and dopant in PEDOT aqueous dispersion II are hydroxypropyl acrylate functionalized sodium polystyrene sulfonate and end-capped non-ionic water-based polyurethane copolymer, in which the functionalized polystyrene sulfonate contains hydroxypropyl acrylate A copolymer with a molar ratio of ester to sodium styrene sulfonate of 1:1, in which the ratio of the amount of initiator to the total molar number of the two monomers is 0.005:1; R(NCO / OH)= 1.6, PEG content 60%; the mass ratio of functionalized sodium polystyrene sulfonate to capped non-ionic water-based polyurethane copolymer is 10:1; the mass ratio of template and dopant to EDOT is 3:1; water dispersion During the preparation process, the molar ratios of oxidant, catalyst and EDOT monomer were 4:1 and 0.001:1, respectively.

[0077] Concrete preparation method and steps are as follows:

[0078] 1. SSS (8.2685g, 0.040mol), hydroxypropyl ...

Embodiment 3

[0088] Example 3 Preparation of poly(3,4-ethylenedioxythiophene) (ie PEDOT) aqueous dispersion Ⅲ

[0089]The template and dopant in PEDOT aqueous dispersion III are functionalized sodium polystyrene sulfonate and end-capped non-ionic waterborne polyurethane copolymer, wherein the functionalized sodium polystyrene sulfonate is hydroxyethyl acrylate and styrene The molar ratio of sodium sulfonate is 1:4 copolymer, the ratio of the amount of initiator to the total molar amount of the two monomers is 0.002:1; the capped nonionic waterborne polyurethane R (NCO / OH) = 1.2, and the PEG content is 10% , the mass ratio of functionalized sodium polystyrene sulfonate to capped non-ionic waterborne polyurethane copolymer is 5:1; the mass ratio of template and dopant to EDOT is 3:1; during the preparation of aqueous dispersion, oxidant, catalyst The molar ratios to EDOT are 1.5:1 and 0.002:1, respectively.

[0090] Concrete preparation method and steps are as follows:

[0091] 1. SSS (8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com