Method for synthesizing malonic ester by one-pot carbonylation

A malonate, chemical synthesis technology, applied in the direction of carbon monoxide or formate reaction preparation, organic chemistry, etc., can solve the problems of long process flow, decompression decomposition, difficult to popularize, etc., achieves simple operation, low production cost, The effect of short production process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

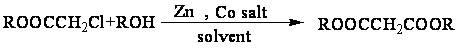

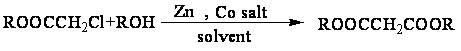

Method used

Image

Examples

Embodiment 1

[0019] Use Zn powder as the reducing agent, and feed according to the molar ratio of zinc and cobalt chloride as 1: 3. 0.96g (0.0040mol) CoCl 2 ﹒ 6H 2 O, 0.52g (0.0080mol) Zn powder, 1.5g (0.011mol) K 2 CO 3 , 23ml (0.394mol) of ethanol and 2ml (0.019mol) of ethyl chloroacetate were added to a 50ml stainless steel reaction kettle with a polytetrafluoroethylene lining, and the air in the kettle was replaced with CO for three times, and then flushed into CO to maintain the pressure 1.2MPa, heated up to 65°C, stirred magnetically for 3 hours, and cooled naturally to room temperature under the protection of carbon monoxide. The composition of the reactor liquid was analyzed by gas chromatography. The conversion rate of ethyl chloroacetate was 97%, and the conversion rate of dimalonate Ethyl ester selectivity was 100%.

Embodiment 2

[0021] With Zn powder as reducing agent, and according to the mol ratio of zinc and cobalt chloride is 1: 1 feed, CoCl 2 ﹒ 6H 2 O-catalyzed carbonylation of ethyl chloroacetate with carbon monoxide for one-pot synthesis of diethyl malonate.

[0022] Others are the same as embodiment 1. The composition of the reactor liquid was analyzed by gas chromatography, the conversion rate of ethyl chloroacetate was 90%, and the selectivity of diethyl malonate was 100%.

Embodiment 3

[0024] With Zn powder as reducing agent, and according to the mol ratio of zinc and cobalt chloride is 0.25: 1 feeding, after magnetic stirring 8 hours, CoCl 2 ﹒ 6H 2 O-catalyzed carbonylation of ethyl chloroacetate with carbon monoxide for one-pot synthesis of diethyl malonate.

[0025] Others are the same as embodiment 1. The composition of the reactor liquid was analyzed by gas chromatography, and the conversion rate of ethyl chloroacetate was 85%, and the selectivity of diethyl malonate was 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com