Method for treating amantadine hydrochloride-containing wastewater by using titanium-containing blast furnace slag as photocatalyst

A technology of amantadine hydrochloride and amantadine hydrochloride, applied in the field of sewage treatment, which can solve the problems of low initial concentration, high COD, and difficult biodegradation of treatable wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

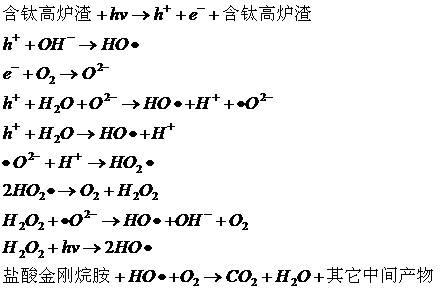

Method used

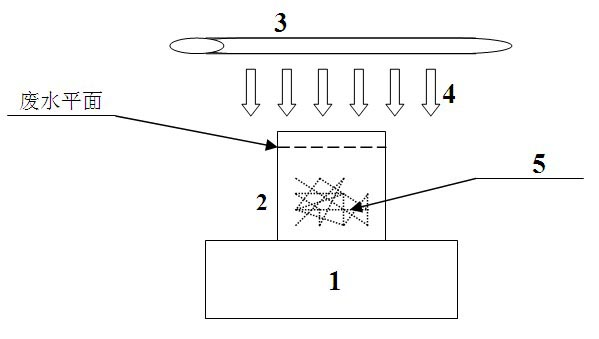

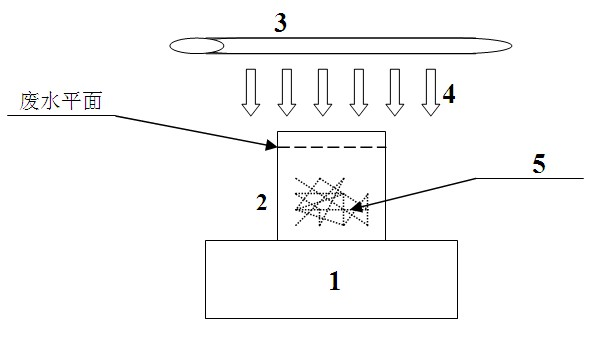

Image

Examples

Embodiment Construction

[0013] A method for treating amantadine hydrochloride wastewater containing titanium-containing blast furnace slag as a photocatalyst. In a 100mL photocatalytic oxidation reactor, the pH values of the wastewater were adjusted to 10.0, 11.0, and 12.0, and the titanium-containing blast furnace slag was used as a photocatalyst. At 12h, 14h, and 16h, the distance between the ultraviolet light and the maximum water surface of the simulated wastewater was controlled at 1cm, 2cm, and 3cm, and the reaction was carried out, and samples were taken regularly. At the end of the reaction, the COD removal rate of amantadine hydrochloride wastewater samples reached 34.23%, 35.12%, 35.88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com