Dissolving pulp sodium lignosulfonate dispersant, and reducing preparation method and application thereof

A technology of sodium lignosulfonate and dissolving pulp, which is applied in the fields of dissolution, chemical instruments and methods, transportation and packaging, etc., and can solve the problem of unsatisfactory dispersion performance of lignosulfonated products, complex composition of dissolving pulp waste liquid, and limited promotion Issues such as the scope of application to achieve the effect of alleviating the crisis, improving the competitiveness of enterprises, and applying a wide range of industries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

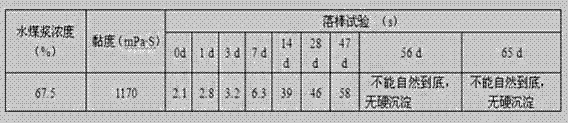

Examples

preparation example Construction

[0026]The reduction preparation method of the dissolving pulp sodium lignosulfonate dispersant comprises the following steps: concentrating the dissolving pulp waste liquid to a solid content of 20-60%, adding a catalyst, and reacting at 40-130°C for 0.5-1.5h; adding acid to adjust Adjust the pH value of the system to 10-13, adjust the temperature to 80-160°C, add sulfonating agent, aldehyde compound, water, and react for 2-5 hours; then adjust the system temperature to 60-130°C, add reducing agent and react again 0.5 ~ 2h to obtain brown black or dark brown liquid, after spray drying to obtain dark brown or dark brown powdery sodium lignosulfonate dispersant; the mass percentage of each raw material is as follows:

[0027] Dissolving pulp waste liquid: 50~85%

[0028] Catalyst: 0.01~0.1%

[0029] Acid regulator: 1.3~5.2%

[0030] Sulfonating agent: 2~8.3%

[0031] Aldehyde compounds: 1.8~8%

[0032] Reducing agent: 0.5~10%

[0033] Water: 2-28%.

[0034] Wherein said di...

Embodiment 1

[0038] (1) Raw material and dosage

[0039] Masson pine dissolving pulp waste liquid (20% solid content): 850.0 Kg

[0040] Mixture of ferrous sulfate and cobalt sulfate (9:1 mass ratio): 0.5 Kg

[0041] Mixture of phosphoric acid and gluconic acid (mass ratio 2:3): 38.5 Kg

[0042] Sodium bisulfite: 20.0 Kg

[0043] Formaldehyde: 55.9 Kg

[0044] Thiourea dioxide: 15.1 Kg

[0045] Water: 20.0 Kg

[0046] (2) Process steps and parameters

[0047] Concentrate the dissolving pulp waste liquid of masson pine to a solid content of 20%, pump 850.0 Kg into the reactor, add 0.5 Kg of a mixture of ferrous sulfate and cobalt sulfate, and react at a temperature of 60°C for 1 hour; add 38.5 The mixture of Kg phosphoric acid and gluconic acid adjusted the pH of the system to 10, raised the temperature to 100°C, and added a mixture of 20.0 Kg sodium bisulfite, 55.9 Kg formaldehyde, and 20.0 Kg water to react for 4 hours; then lowered the system temperature to 90°C, added 15.1 Kg of ...

Embodiment 2

[0049] (1) Raw material and dosage

[0050] Masson pine and birch dissolving pulp waste mixture (mass ratio 3:2, solid content 26%): 844 Kg

[0051] Mixture of ferrous sulfate, copper sulfate and cobalt sulfate (mass ratio 7:2:1): 0.2 Kg

[0052] Mixture of sulfamic acid and amino acid (mass ratio 1:1): 23.5 Kg

[0053] Mixture of sodium bisulfite and sodium sulfite (mass ratio 2: 1): 58.4 Kg

[0054] Mixture of formaldehyde and paraformaldehyde (mass ratio 4:1): 18.0 Kg

[0055] Mixture of sodium dithionite and thiourea dioxide (mass ratio 1:1): 5.0 Kg

[0056] Water: 50.9 Kg

[0057] (2) Process steps and parameters

[0058] Concentrate the masson pine and birch dissolving pulp waste liquid mixture to a solid content of 26%, pump 844.0 Kg into the reactor, and add 0.2 Kg of ferrous sulfate, copper sulfate and cobalt sulfate mixture, at a temperature of 70 ° C 23.5 Kg of sulfamic acid and amino acid mixture were added to adjust the pH of the system to 12, and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com