Palladium-based dual functional film and its preparation method

A dual-function, palladium-based technology, applied in separation methods, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as hydrogen consumption, reduce costs and energy consumption, and achieve the effects of simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

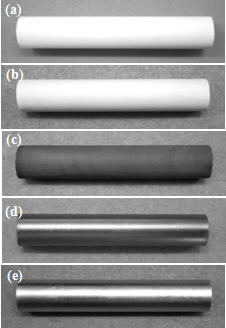

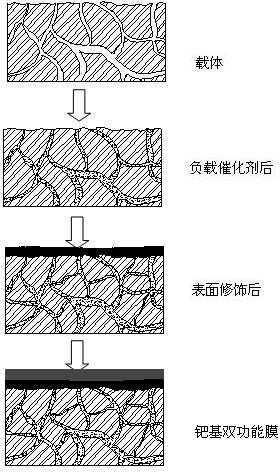

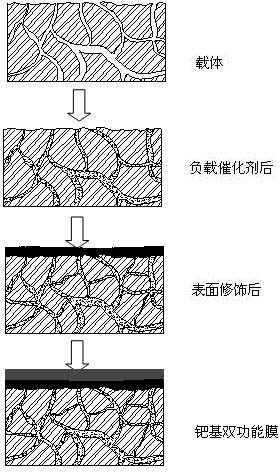

[0038] A palladium-based bifunctional membrane, comprising a palladium membrane deposited on the surface of a tubular porous ceramic, a methanation catalyst is loaded in the porous ceramic channel, and its preparation method comprises the following steps (see figure 1 and figure 2 ):

[0039] (1). A tubular porous ceramic with an average pore size of 3 μm and a maximum pore size of 9 μm was selected as the carrier of the bifunctional membrane. Before use, the carrier was first cleaned with commercially available detergent, then boiled and washed with hot deionized water, and then dried in an oven at 120°C.

[0040] (2). Immerse the support in saturated Ni(NO 3 ) 2 solution, take it out after 24 hours, and dry it in an oven at 120°C. Then the impregnated carrier was calcined at 450 °C in an air atmosphere for 3 hours. from figure 2 From (a) to (c), it can be seen that the surface of the carrier is uniformly covered with NiO particles after being impregnated and calcine...

Embodiment 2

[0046] A palladium-based bifunctional membrane comprises a palladium membrane deposited on the surface of a porous ceramic, and a methanation catalyst is loaded in the pores of the porous ceramic, and its preparation method comprises the following steps:

[0047] (1). Asymmetric porous ceramics with an average pore size of 0.1 μm and a maximum pore size of 0.2 μm were selected as the carrier of the bifunctional membrane. Before use, the carrier was first cleaned with commercially available detergent, and then washed with hot deionized water. , and then dried in an oven at 120°C.

[0048] (2). Immerse the support in Pd(OH) 2 In the colloid (the preparation of the colloid: weigh 0.2 g PdCl 2 Add 0.06 g NaOH to 20 ml deionized water, shake well, and ultrasonically shake for 0.5 hours), take it out after 24 hours, and dry it in an oven at 120 °C. Then the impregnated carrier was calcined at 450 °C in an air atmosphere for 3 hours.

[0049] (3). The palladium film was prepared b...

Embodiment 3

[0053] A palladium-based bifunctional membrane comprises a palladium membrane deposited on the surface of a porous ceramic, and a methanation catalyst is loaded in the pores of the porous ceramic, and its preparation method comprises the following steps:

[0054] (1). Asymmetric porous ceramics are selected as the carrier, with an average pore size of 0.5 μm and a maximum pore size of about 5 μm. The carrier was washed with commercially available detergent, washed with deionized water, and then dried in an oven at 120 °C.

[0055] (2). The sol-gel method is used to modify the carrier to increase the specific surface area of the carrier. The composition of the sol and the ratio of each component are: γ-AlOOH sol, polyethylene glycol and 8 wt.% polyvinyl alcohol, and the volume ratio of the three is 1: 0.007: 0.2. The carrier channels and inner and outer surfaces were dip-coated with sol by vacuum impregnation method, and then aged in a constant temperature and humidity box a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com