Flame-retardant viscose/aramid 1313 blended camouflage fabric, active carbon fiber fabric and PTFE (polytetrafluoroethylene) film combined multifunctional protective fabric

A technology of activated carbon fiber cloth and flame-retardant viscose, applied in protective clothing, textiles, papermaking, textiles, etc., can solve problems such as penetration, weakening of protective performance, loss of protective clothing function and meaning, and achieve long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

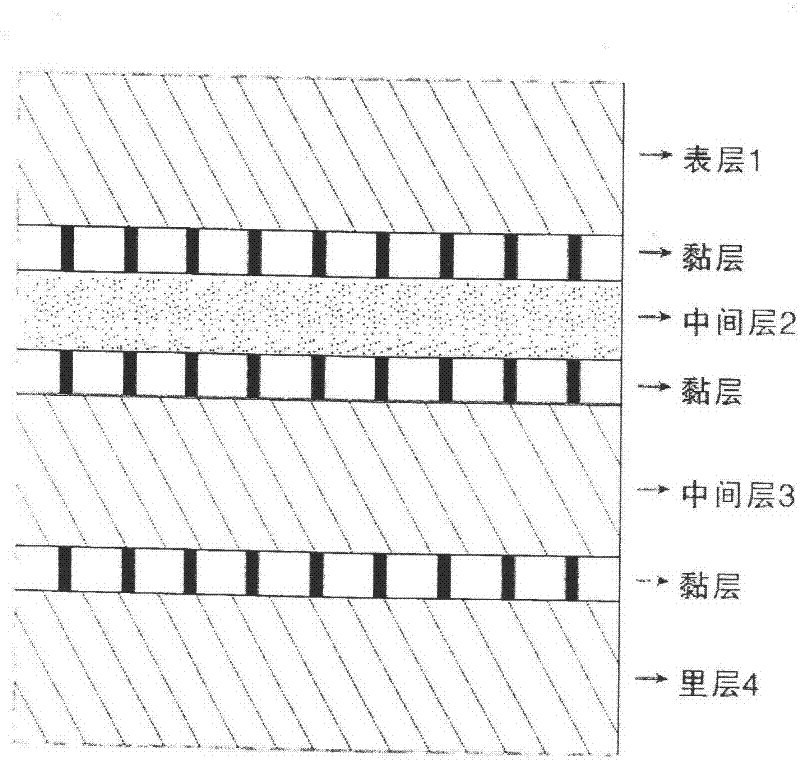

[0020] figure 1 As shown, it includes surface layer 1, middle layer 2, middle layer 3 and inner layer 4.

[0021] The surface layer 1 fabric warp and weft are all selected 32 s / 2 Flame-retardant viscose / aramid 1313 and carbon black conductive fiber blended yarn, warp density 320 / 10cm, weft density 256 / 10cm, warp weight 196.5g / m, weft weight 159.7g / m, the warp And the weft adopts two up and one down twill weave;

[0022] Described middle layer 2 selects polytetrafluoroethylene (PTFE) clothing film for use;

[0023] Described middle layer 3 selects active carbon fiber for use, and warp thread and weft thread all select 60 for use s / 2 Activated carbon fiber (ACF) has a warp density of 250 / 10cm, a weft density of 180.5 / 10cm, a warp weight of 85.5g / m, and a weft weight of 61.5g / m. The warp and weft adopt two upper and two lower twill weaves;

[0024] The inner layer 4 is made of 75D / 48F moisture-absorbing and sweat-wicking polyester low elastic yarn with a grammage of 160...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com