High-pressure gas cylinder for gas transportation vehicle

A high-pressure gas cylinder and gas technology, applied in pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve problems such as gas volume limitations, improve service life, ensure surface quality, and avoid resin brittleness increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

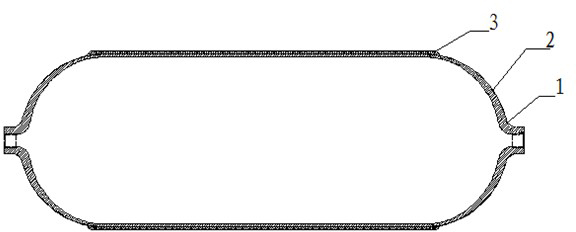

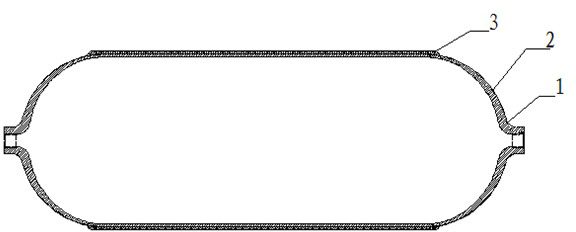

[0026] Such as figure 1 As shown, the high-pressure gas cylinder used for the transportation vehicle is a steel-lined glass fiber hoop-wound gas cylinder with a volume of 200 L to 400 L and a working pressure of 25 MPa to 35 MPa. The high-pressure gas cylinder includes a barrel section located in the middle, two bottle mouths located at both ends and a head connecting the barrel section and the bottle mouth, and its walls include: an inner tank 1 made of steel; A bonded coating 2 made; a composite material layer 3 made of glass fiber-epoxy system composite material; an outer protective film.

[0027] The liner 1 is made of chromium-molybdenum steel pipes in the way of spinning and closing. It provides space for storing compressed natural gas, directly contacts with the filling medium, acts as a seal and holds a part of the pressure. After the liner 1 is processed and shaped, heat treatment is required. The steps are: put the liner in a heating furnace, heat it to 860°C to 910...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com