Open gear lubricating grease composition

A kind of grease composition and open gear technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of bad environmental impact, unsuitable grease, difficult to carry out, etc., and achieve excellent environmental friendliness, excellent extreme pressure and anti-wear performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0049] Add 40 parts (40%) of soybean oil and 25 parts (25%) of pentaerythritol ester into a small test kettle, raise the temperature to 85°C, stir for 10 minutes, add 20 parts (20%) of polyisobutene, stir for 15 minutes, add 15 part (15%) of lithium-based grease, stirred for 20 minutes, and then based on the total amount of base oil and thickener as 100%, add 0.5% diisooctyl diphenylamine, 2% dialkyl dithioaminomethyl ester, 8% potassium borate, 1% dialkyl dithiophosphate, 3% sulfurized olefin cottonseed oil, 10% graphite and 2% molybdenum disulfide. Finally, grind and homogenize on three-axis rollers, and measure the grease performance.

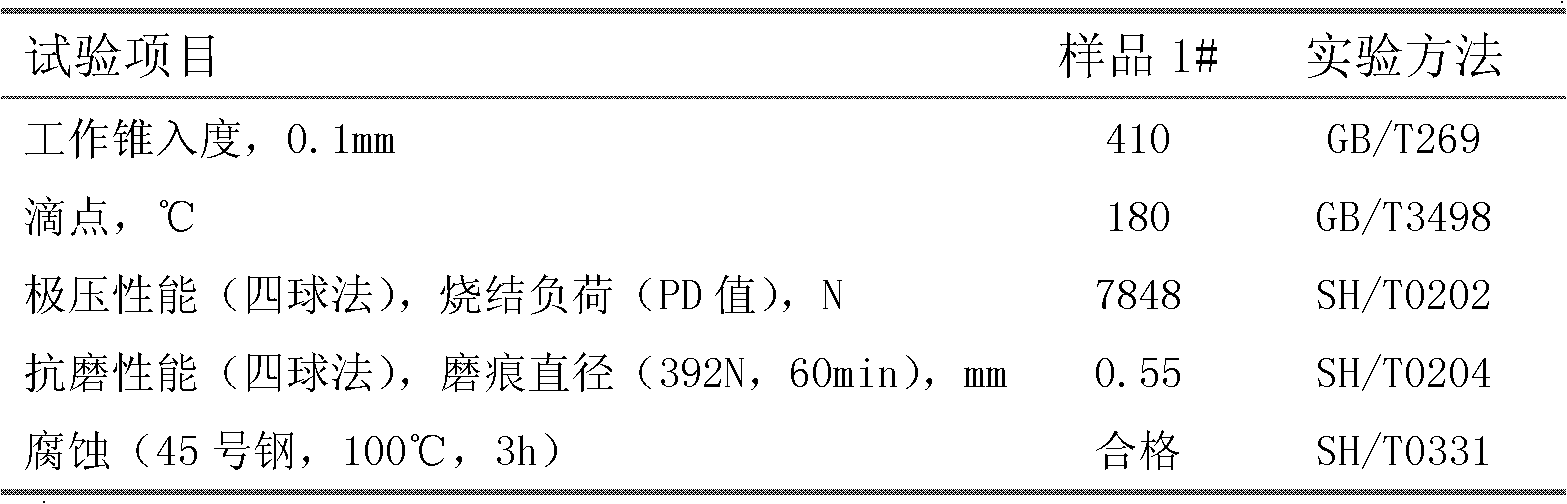

[0050] The performance of the lubricating grease that process formula of the present invention makes is listed in table 1

[0051] Table 1

[0052]

example 2

[0054] Add 50 parts (50%) of cottonseed oil and 15 parts (15%) of dipentaerythritol ester into a small test kettle, raise the temperature to 90°C, stir for 10 minutes, add 10 parts (10%) of polyisobutylene, stir for 15 minutes, add 25 parts (25%) of composite aluminum-based grease, stirred for 20 minutes, then based on the total amount of base oil and thickener as 100%, add 0.5% diphenylamine, 5% dialkyl dithiocarbamate , 4% borate ester, 3% potassium borate, 3% dialkyl dithiophosphate, 10% sulfurized olefin cottonseed oil, 2% calcium petroleum sulfonate, 3% graphite and 5% molybdenum disulfide. Finally, grind and homogenize on three-axis rollers, and measure the grease performance.

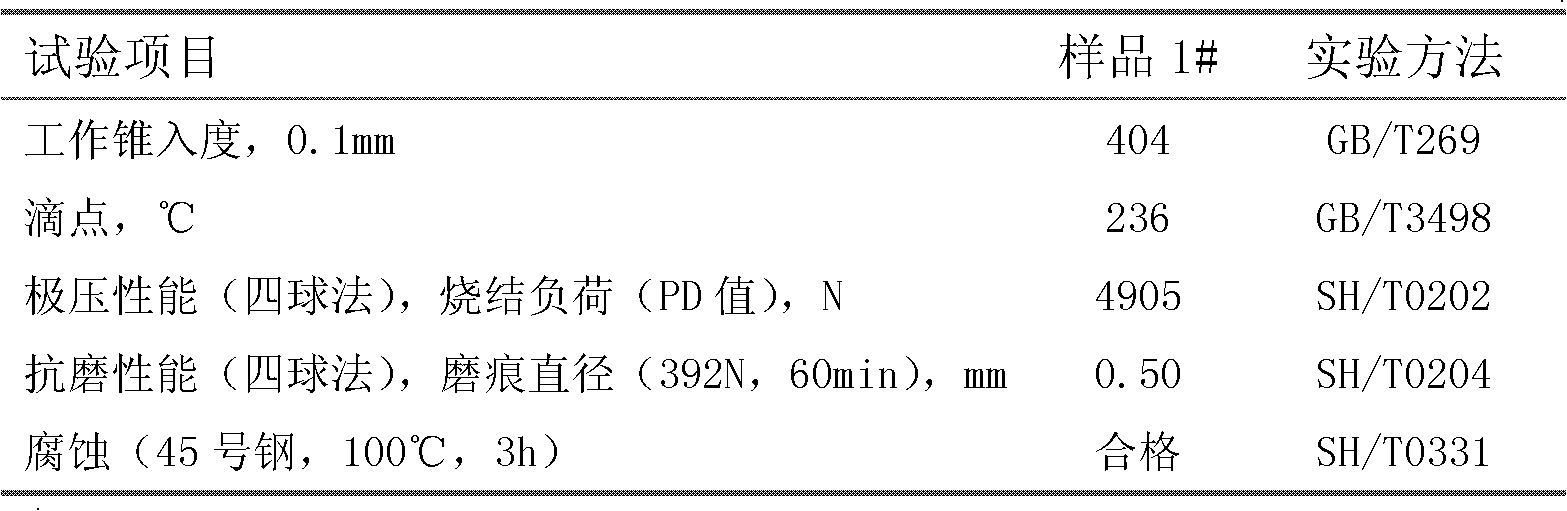

[0055] The performance of the lubricating grease that process formula of the present invention makes is listed in table 2

[0056] Table 2

[0057]

example 3

[0059] Add 45 parts (45%) of castor oil and 20 parts (20%) of pentaerythritol ester into a small test kettle, raise the temperature to 90°C, stir for 10 minutes, add 15 parts (15%) of polyisobutene, stir for 15 minutes, add 20 parts of (20%) lithium / calcium-based grease, stirred for 20 minutes, then based on the base oil and thickener as 100%, add 1% diphenylamine, 3% dialkyl dithiocarbamate, 2% borate ester, 5% potassium borate, 2% dialkyl dithiophosphate, 6% sulfurized olefinic cottonseed oil, 1% calcium petroleum sulfonate, 4% graphite and 8% molybdenum disulfide. Finally, grind and homogenize on three-axis rollers, and measure the grease performance.

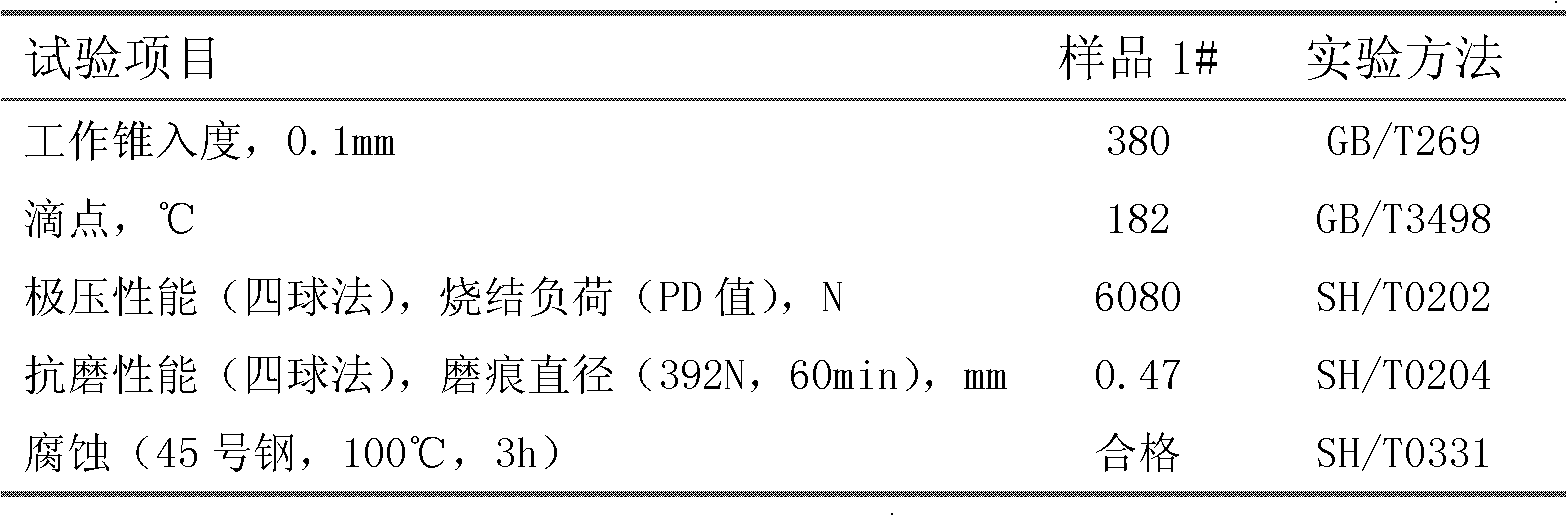

[0060] The performance of the lubricating grease that process formula of the present invention makes is listed in table 3

[0061] table 3

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com