Antistatic flame-retardant ultra high molecular weight polyethylene composition and preparation method thereof

A technology of ultra-high molecular weight and composition, applied in the field of polymer materials and their molding and processing, can solve problems such as no literature reports, and achieve the effects of enhancing compatibility, improving processing rheological properties, and excellent antistatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

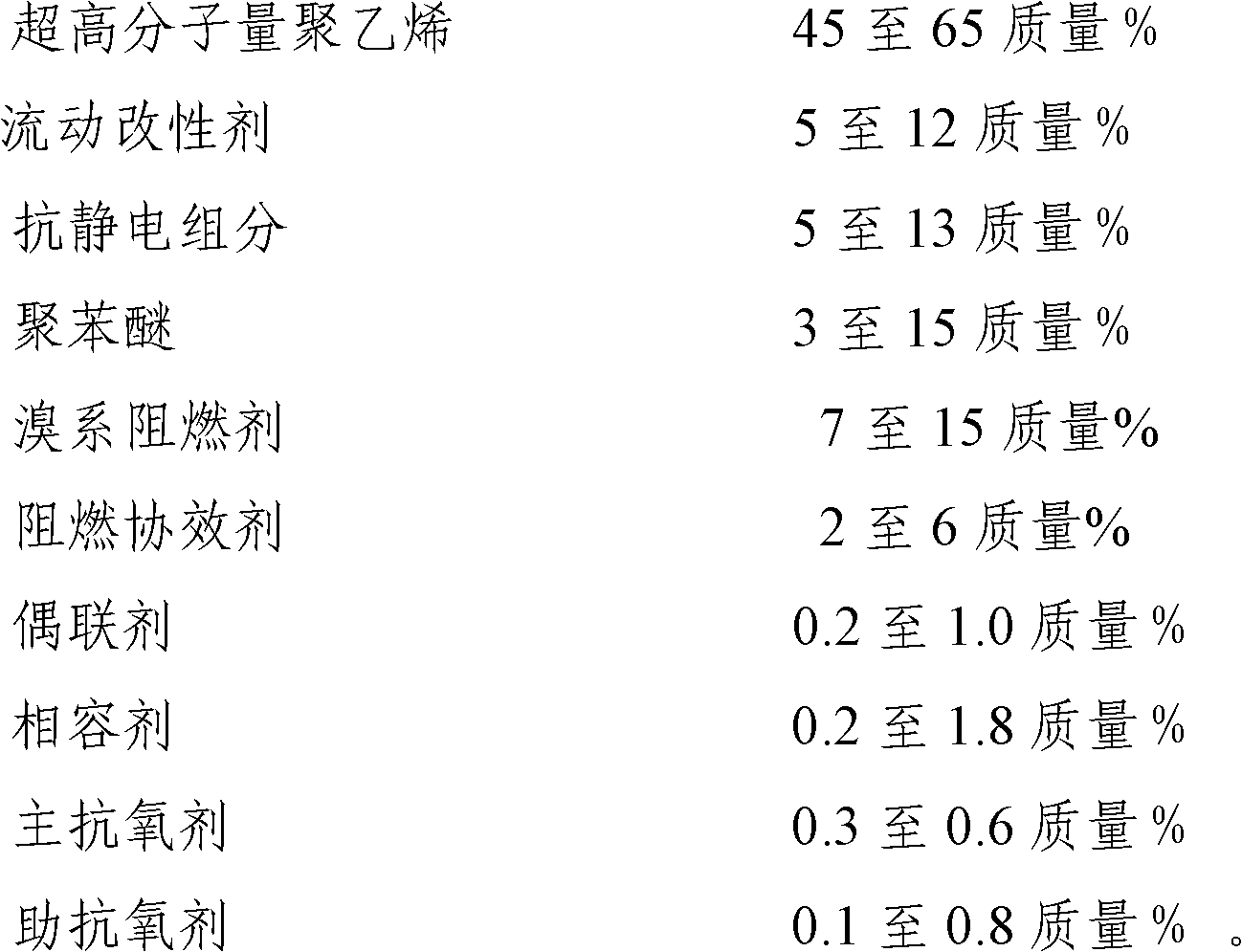

Method used

Image

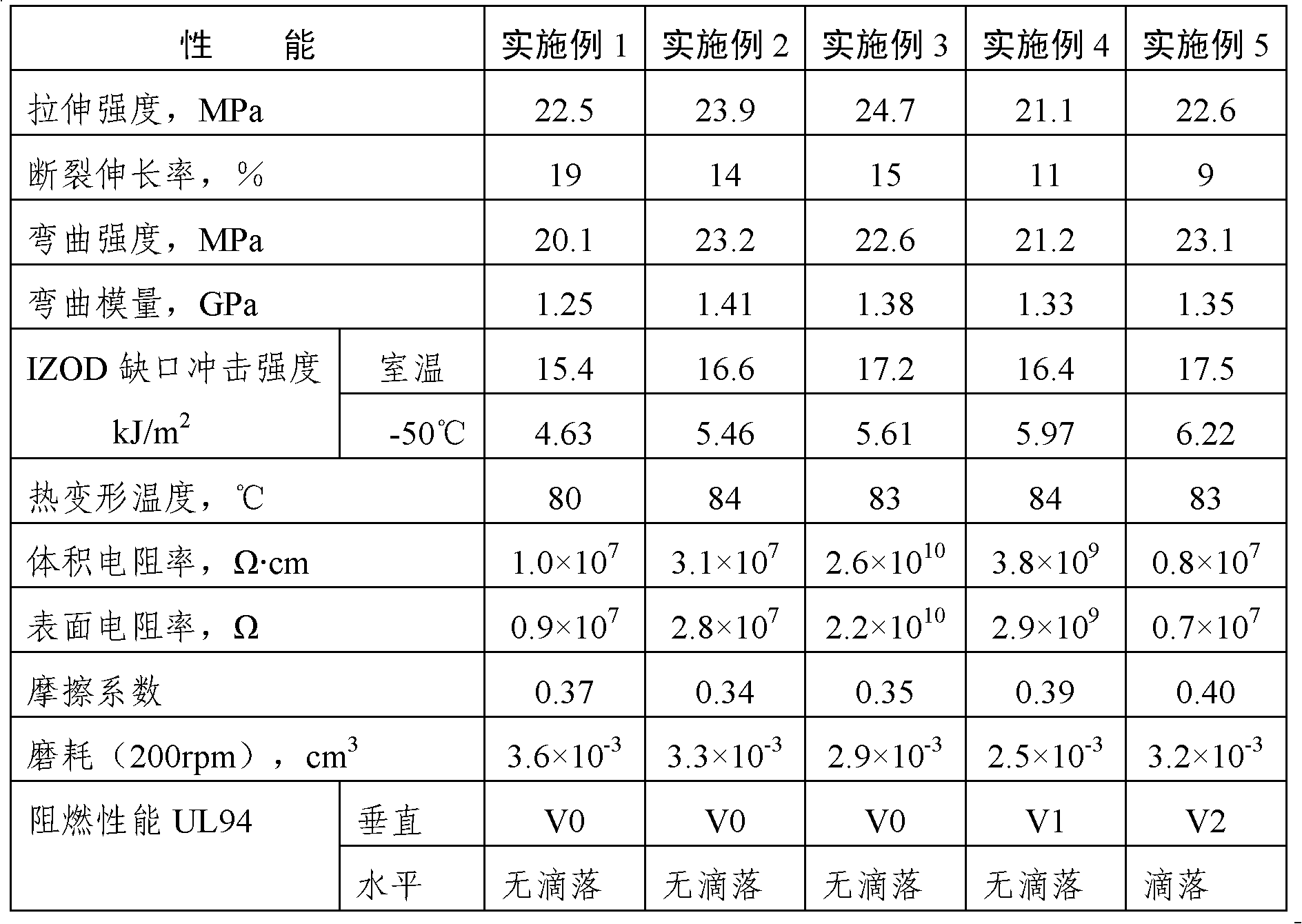

Examples

Embodiment 1

[0050] (1) Premixing: First, add polyphenylene ether, brominated flame retardant, and flame retardant synergist to the low-speed mixer in sequence according to the ratio shown in Table 1 for premixing. The mixing temperature is 50° C., the rotation speed of the mixer is 60 rpm, and the mixing time is 8 minutes. The three components are ground and mixed to form a PPE composite flame retardant. Then, add conductive carbon black, graphite, coupling agent, and compatibilizer in turn according to the ratio shown in Table 1, and continue mixing under the same conditions. The output is called Premix 1.

[0051] (2) High-speed mixing: add ultra-high molecular weight polyethylene, flow modifier, premix 1 in step (1), primary antioxidant and secondary antioxidant to the high-speed mixer in sequence according to the ratio shown in Table 1 premixed. The mixing temperature is 30° C., the rotation speed of the mixer is 200 rpm, and the mixing time is 5 minutes.

[0052] (3) Extrusion gr...

Embodiment 2

[0054] (1) Premixing: First, add polyphenylene ether, brominated flame retardant, and flame retardant synergist to the low-speed mixer in sequence according to the ratio shown in Table 1 for premixing. The mixing temperature is 55°C, the speed of the mixer is 50 rpm, and the mixing time is 10 minutes. The three components are ground and mixed to form a PPE composite flame retardant. Then, add conductive carbon black, graphite, coupling agent, and compatibilizer in turn according to the ratio shown in Table 1, and continue mixing under the same conditions. The output is called premix 2.

[0055] (2) High-speed mixing: add ultra-high molecular weight polyethylene, flow modifier, premix 2 in step (1), primary antioxidant and secondary antioxidant to the high-speed mixer in sequence according to the ratio shown in Table 1 premixed. The mixing temperature is 35° C., the rotation speed of the mixer is 150 rpm, and the mixing time is 4 minutes.

[0056] (3) Extrusion granulation: ...

Embodiment 3

[0058] (1) Premixing: First, add polyphenylene ether, brominated flame retardant, and flame retardant synergist to the low-speed mixer in sequence according to the ratio shown in Table 1 for premixing. The mixing temperature is 50°C, the speed of the mixer is 50 rpm, and the mixing time is 5 minutes. The three components are ground and mixed to form a PPE composite flame retardant. Then, add conductive carbon black, graphite, coupling agent, and compatibilizer in turn according to the ratio shown in Table 1, and continue mixing under the same conditions. The output is called premix 3.

[0059] (2) High-speed mixing: Add ultra-high molecular weight polyethylene, flow modifier, premix 3 in step (1), primary antioxidant and secondary antioxidant to the high-speed mixer in sequence according to the ratio shown in Table 1 premixed. The mixing temperature is 25° C., the rotation speed of the mixer is 200 rpm, and the mixing time is 3 minutes.

[0060] (3) Extrusion granulation: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com